The Vertical Turning Technology

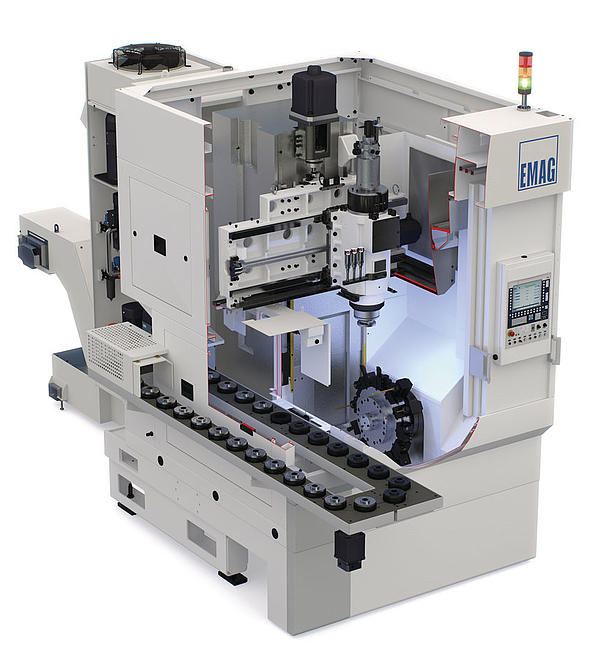

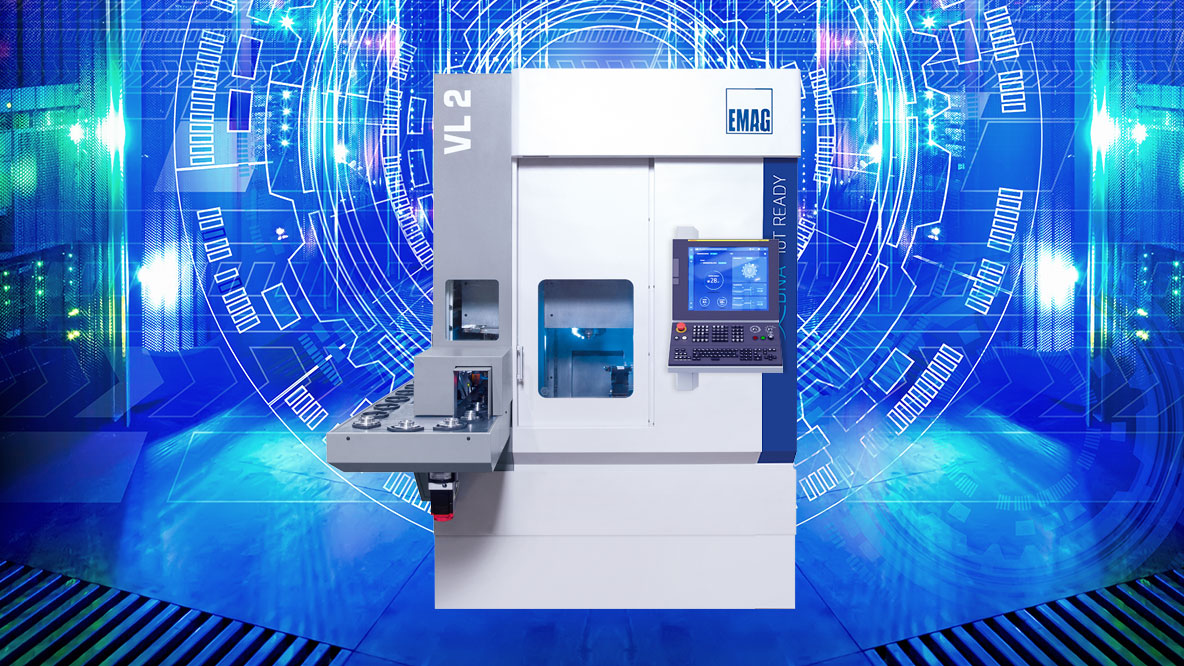

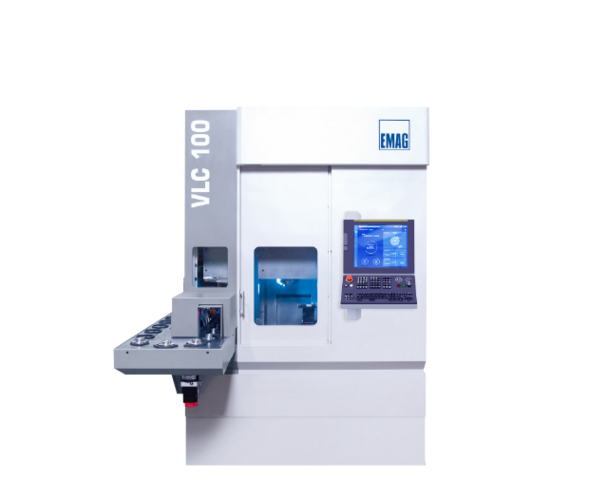

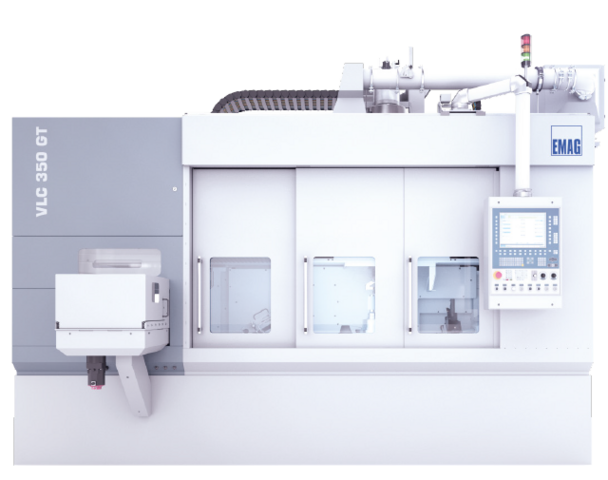

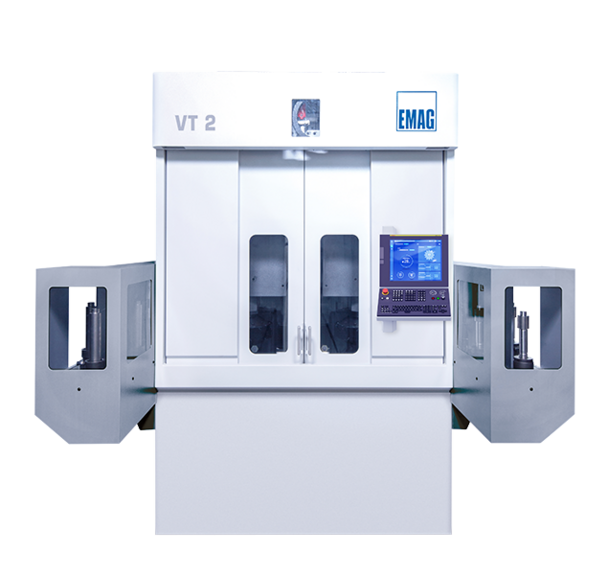

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process with suspended spindle. In vertical turning with suspended spindle (also called vertical „pick-up“ turning) the workspindle takes over both the workholding function for the machining process (vertical turning, drilling, milling, ...) and the automation process. So called vertical turning machines or vertical pick-up turning machines are primarily used in the manufacture of large batches of high-quality metal components.

EMAG’s first, world-renowned series of vertical turning machines was the VSC. But what began life as a machine for vertical turning soon developed into a multi-functional production centre.

Vertical turning is a highly productive process for the machining of round workpieces

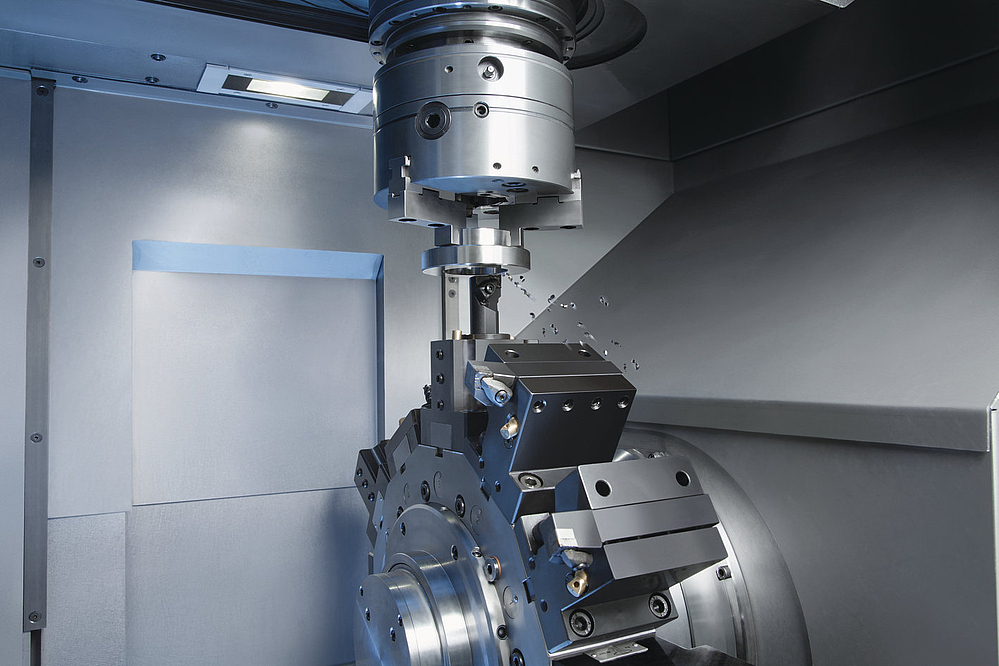

When vertical turning (on vertical pick-up turning machines) was first contemplated, the experts asked themselves: What will be the advantage if the mainspindle of a turning machine collects the workpiece like a movable pick-up arm, holds it during machining and afterwards unloads it? The answer is obvious. Practically every application will show enormous time savings, as different processes are combined in one continuous, compact cycle. An important core element of the vertical turning machine is the overhead slide with integrated pick-up spindle. It carries the quill that contains the workspindle and travels in X, Y and Z axis.

Other advantages of the VL and VSC machines are their extreme rigidity, high rapid travers speeds, short strokes and an integral cooling system that guarantees precision, great productivity rates and short idle times.

How a vertical pick-up turning machine works

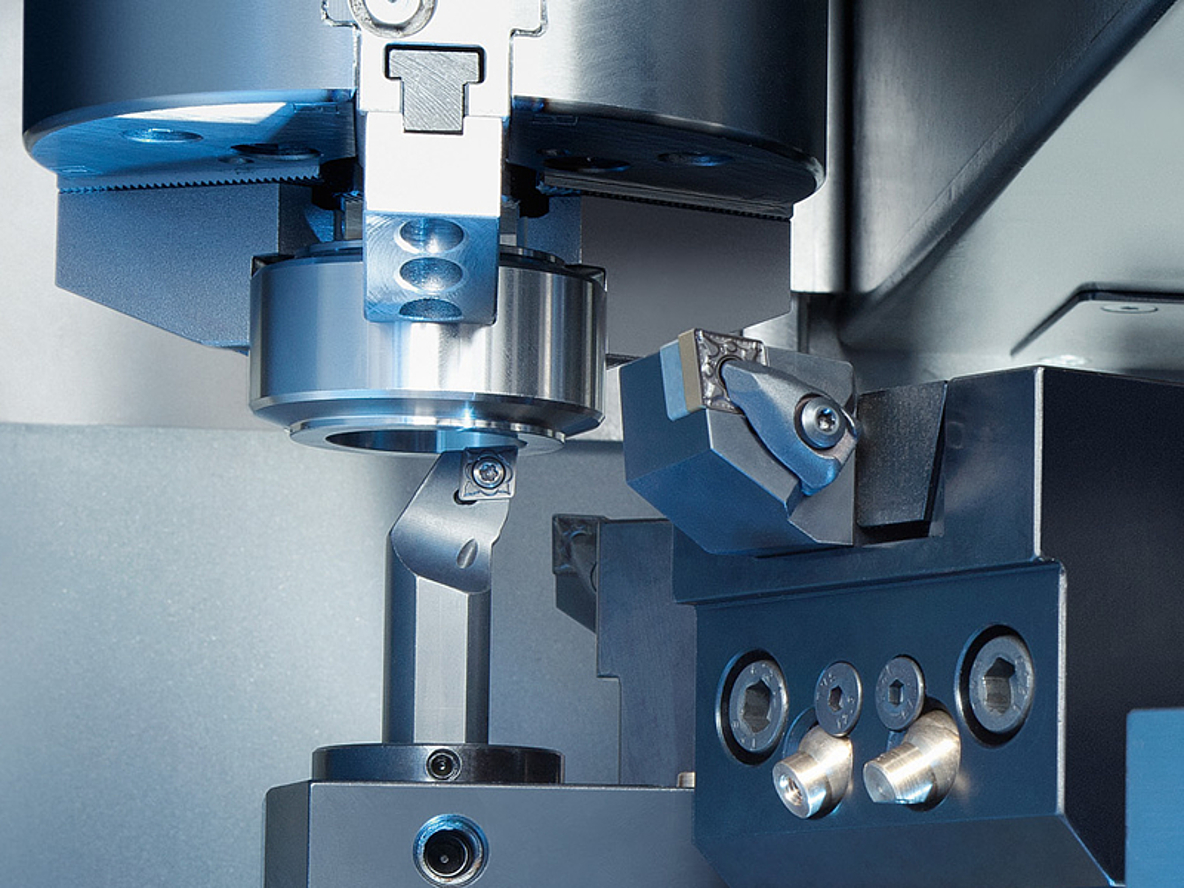

The mainspindle with the workpiece carries out all necessary movements in the machine axes. The traverse from collection point to machining point of the workpiece and the removal of the finished component, are carried out at speed.

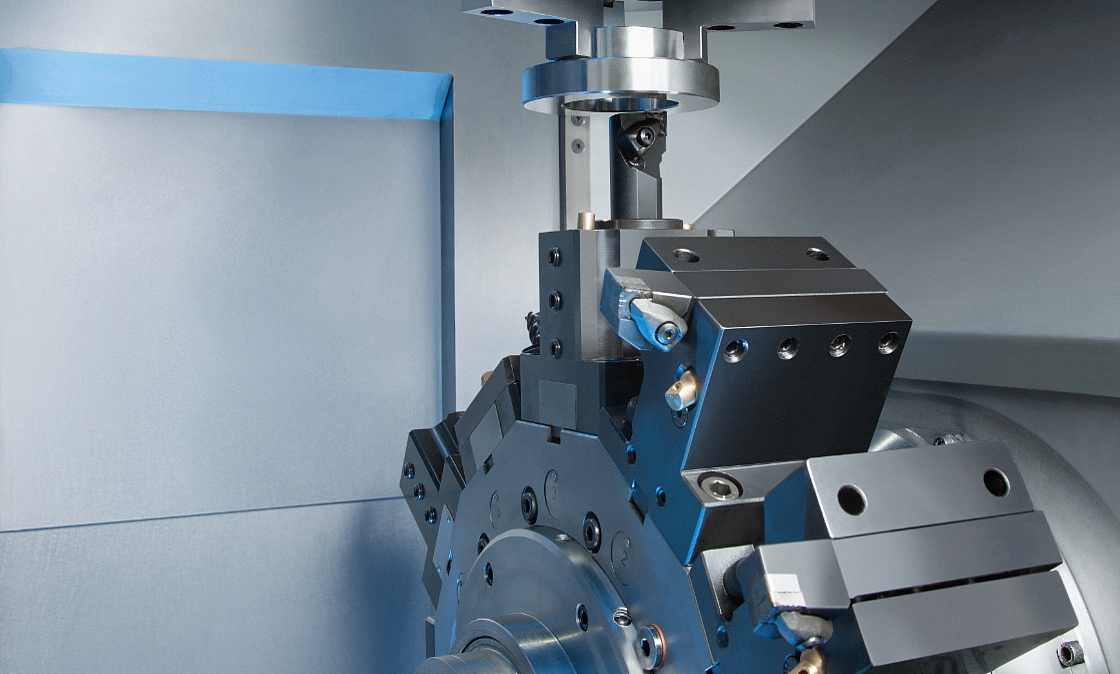

The tool is firmly fixed below the workpiece and never moves during the vertical turning operation (machining).

Many successes scored in the application of vertical turning

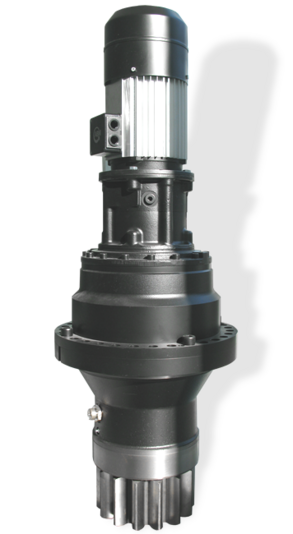

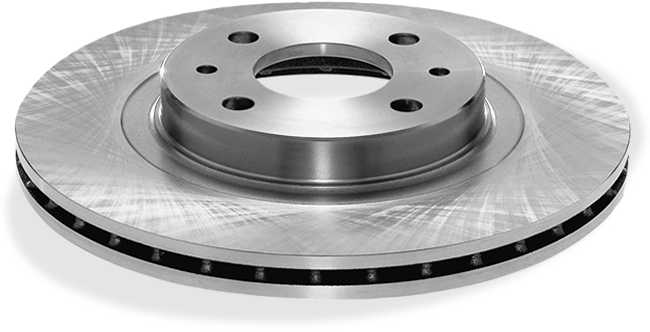

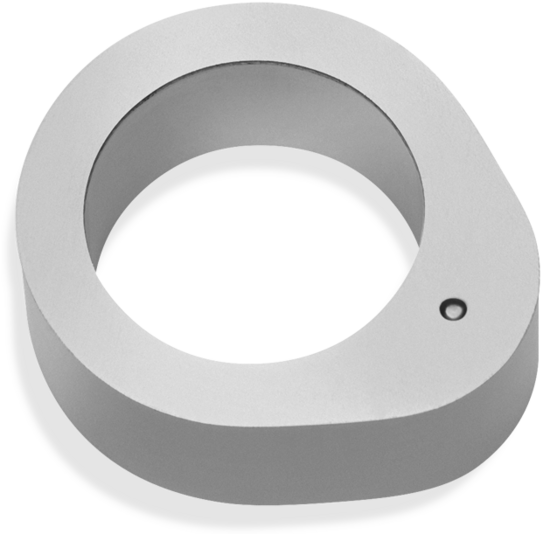

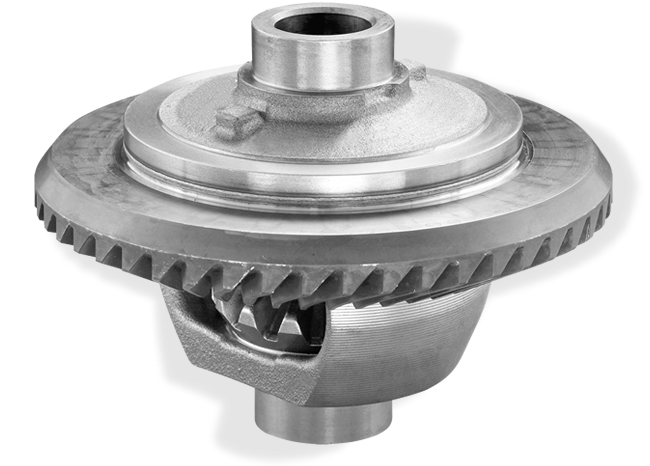

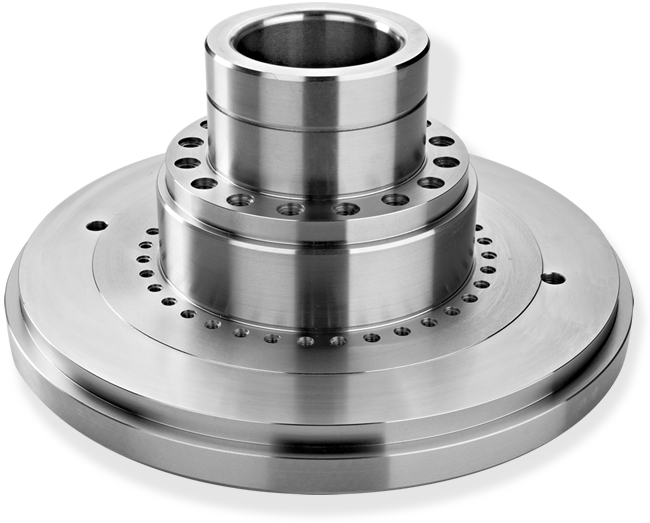

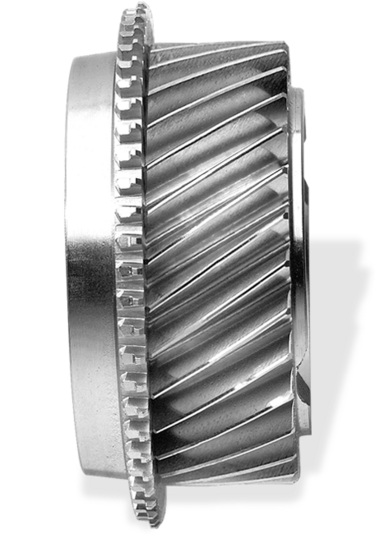

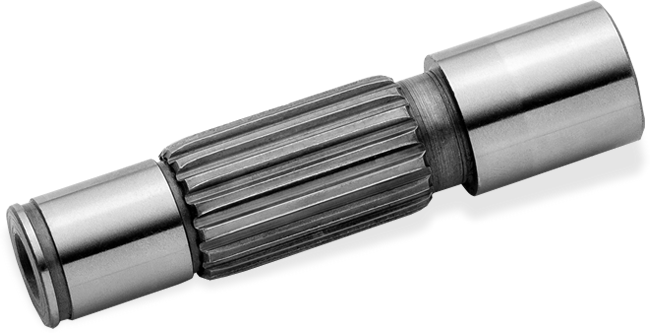

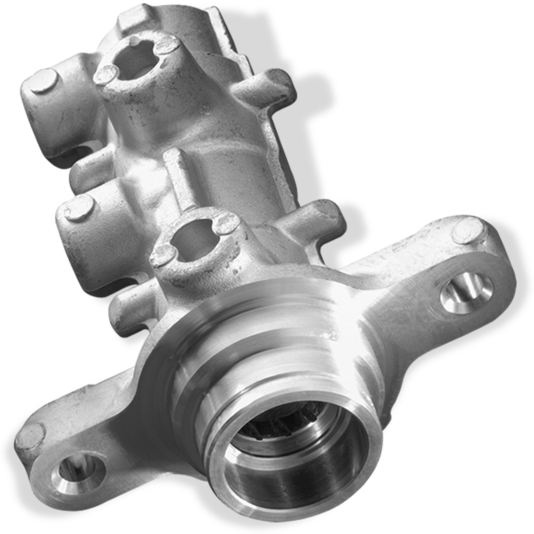

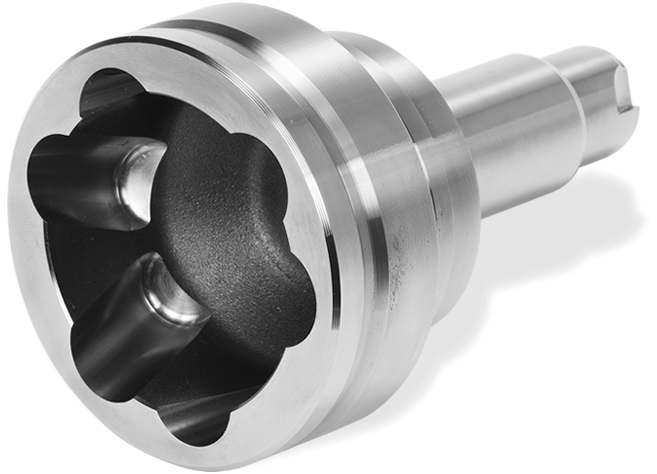

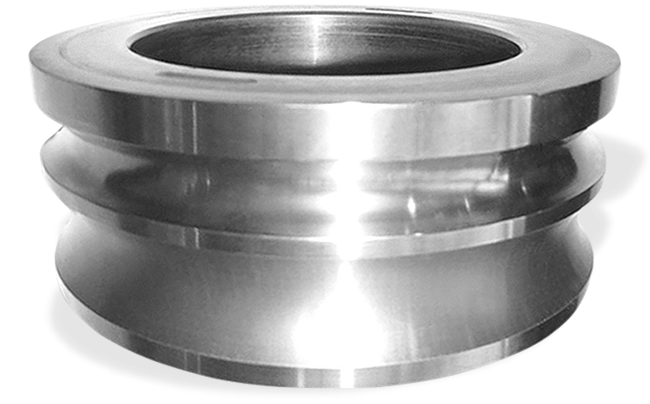

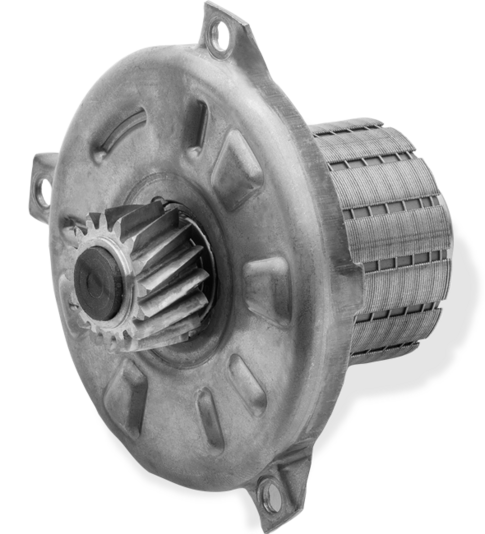

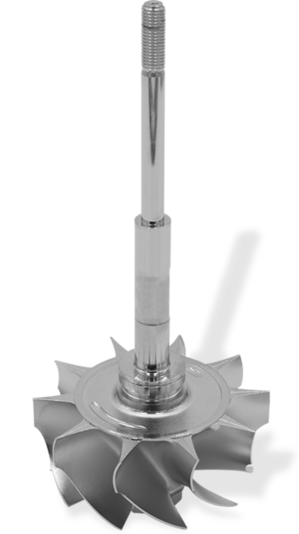

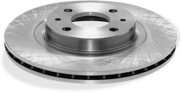

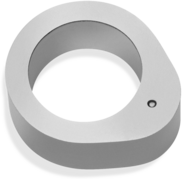

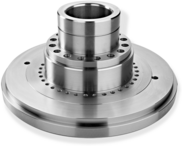

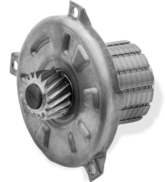

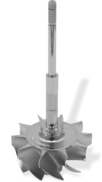

The advantages provided by the highly stable, vertical design of the EMAG vertical turning machine are made obvious by the many applications for which it is being used in the field. In the production of gearwheels, sprockets, sliding sleeves, components for CVTs, link pins, conrods, rockers, bearing rings and piston rings the position of the tool – below the workpiece – is the first decisive advantage.

This design offers ideal chip flow conditions and makes dry machining an uncomplicated process.

Stability – another advantage of vertical turning

All EMAG vertical turning machine assemblies – for instance the base in polymer concrete and the tooling system (turret) firmly integrated in the machine base – are of a stable and vibration resistant design.

Workpieces

The Right Manufacturing Solution for Every Workpiece

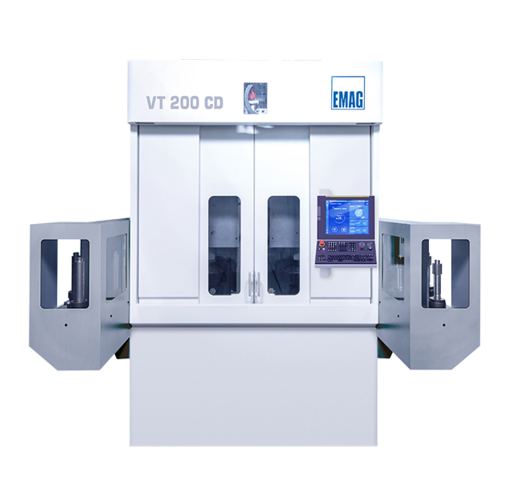

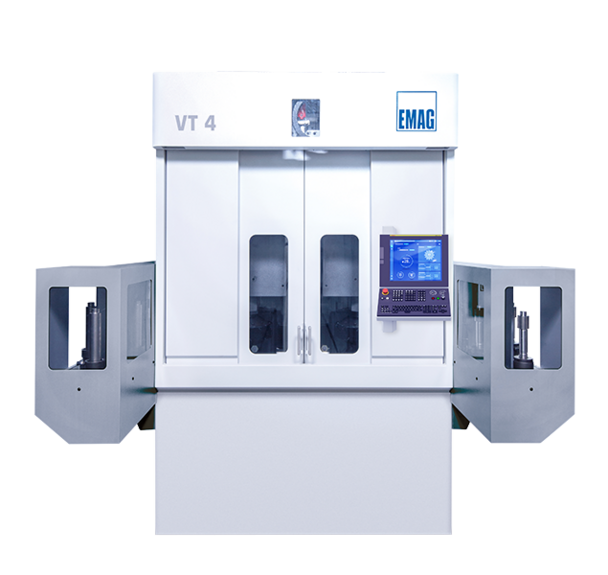

Machines for your requirements

(22) machines found

Manufacturing lines