Machines and manufacturing systems for the machining of steering pinions

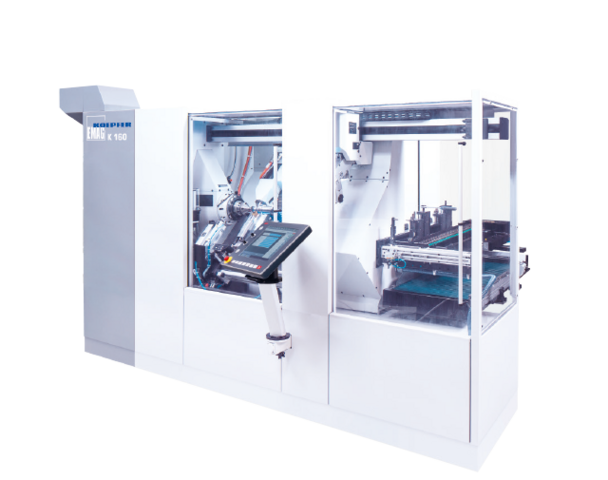

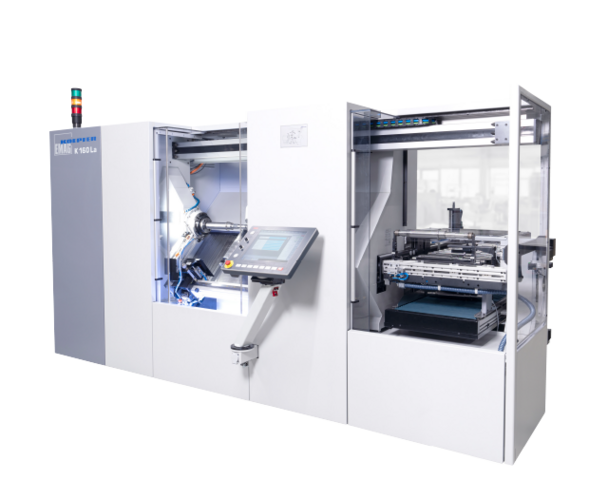

These days, power steering systems are standard in all cars. It is the reason why the steering pinion that transfers the movement of the steering wheel to the steering system’s gear shaft is produced in enormous quantities. For the KOEPFER 160 Hobbing Machine this is a simple task, as it is specially designed for the manufacture of steering pinions. The machine features a cutting-edge 8-axis control and offers high speeds on both hobbing head and mainspindle. It allows for the milling of even the smallest number of teeth on shafts and steering pinions at high cutting speeds.

Machining of steering pinions on K 160 machines.

An integrated loading gantry ensures the automatic loading and unloading of all workpiece variants. A workpiece positioning check and – where necessary – adjustment is carried out early on, when the component is still in the loading magazine. This is necessary, as the gearing on the steering pinion must be machined in alignment with a contour (surface, fluted section).

| Material | 14NiCr14 |

| Machining technologies | soft pre-milling and hard finishing (skiving) of the gearing |

| Machining quality |

|

| Workpiece variants | 2 x 10 steering pinion variants, with left- and right-hand pitched gearing respectively |

| Cycle times |

|

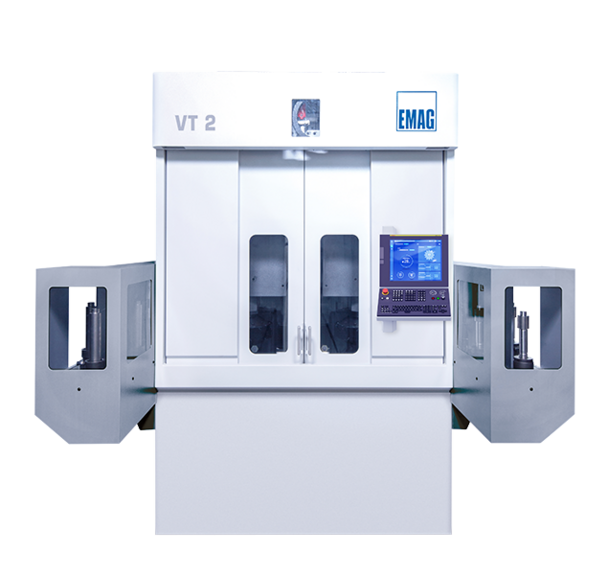

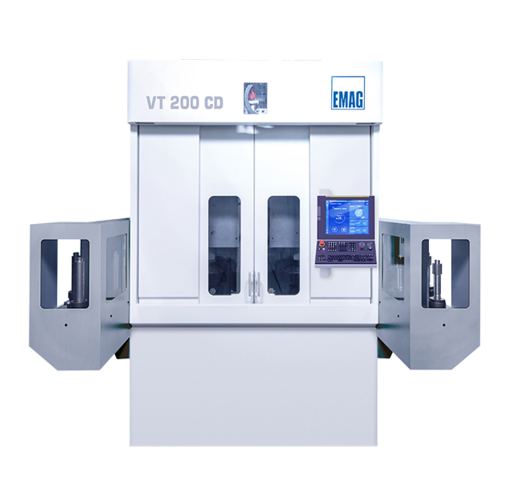

Manufacturing system for steering pinions

What does a modern, highly productive and cost-efficient manufacturing system for steering pinions look like? The answer to the question: like the VL and VT machines from EMAG.

VL/VT production line for steering pinions

The most important facts about the line:

- The 4-axis machining capability brings about an increase in productivity of 30 percent

- Short travels, resulting in short idle times

- Machining in a limited number of setups ensures highest precision (no re-clamping errors)

- A saving in footprint of 15 percent

- Simple resetting and easy maintenance make the machines operator-friendly

VL/VT production line for steering pinions

The most important facts about the production environment:

- Universal, modular manufacturing concept that can be adapted and extended at any time

- Minimal incidental costs, as there is no need for intermediate storage or in-house transport of the workpieces, resulting in low stocks and faster throughput times

- Simple incorporation of own design, specific automation solutions

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

The combination of a number of processes – such as hard turning and grinding – on a single machine, allows for the exploitation of considerable…

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process…

Machines for your requirements

(5) machines found