History

EMAG starts construction of a new plant in Mexico

On June 19, 2023, the symbolic groundbreaking ceremony was held for the EMAG Group's new plant in the San Isidro Business Park in Querétaro, Mexico. This marks the start of an ambitious investment program by the EMAG Group in the region.

The EMAG Group founds a new sales company, EMAG Middle East, based in the International Free Zone Authority (IFZA) in Dubai.

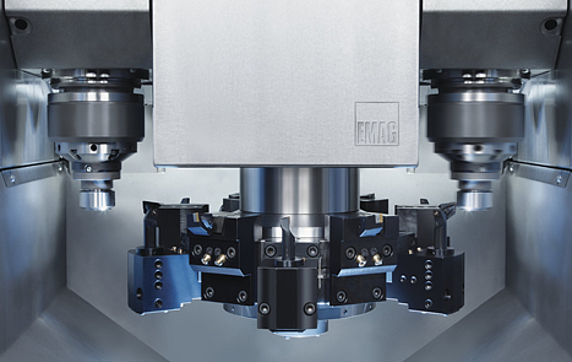

EMAG presents combination machining power skiving and turning for complex gearing solutions

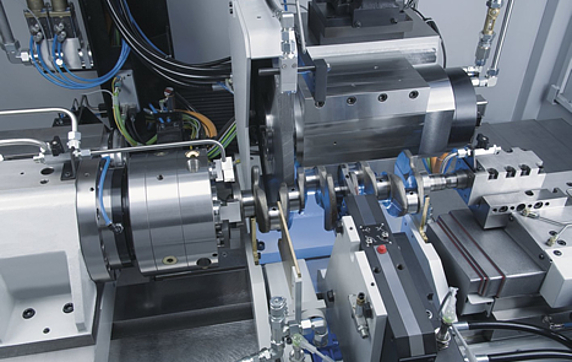

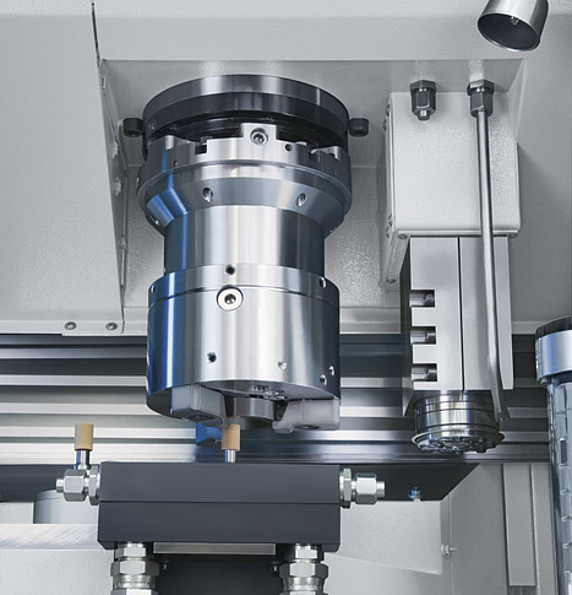

Power skiving is becoming increasingly important in the production of tooth profiles, as it is faster than the shaping process and more flexible than hobbing and broaching. The new VSC 400 PS from EMAG simplifies the previously complex process through simple operation and the ability to efficiently and reliably machine complex components in a single setup.

EMAG SU opens new production plant in Anzola

EMAG S.p.A., the EMAG Group's specialist for tooth flank grinding, gear shaving, power skiving, profile grinding and gear generating grinding, opens its new production plant in Anzola, Bologna, Italy.

Laser Metal Deposition: EMAG develops production solution for hard coating of brake discs

EMAG presents manufacturing solution for the brake disk of the future. The car brake disk of the future is wear-resistant - and lasts the life of the car. This is made possible by a two-layer hard coating that is applied to the disk by laser welding. For the first time, EMAG is presenting the complete brake disc machining process from soft machining to coating and hard machining.

Samputensili Machine Tools and Samputensili CLC have become EMAG SU

The acquisition of Samputensili Machine Tools and Samputensili CLC by the EMAG Group - including the 87 employees across two sites near Bologna and Reggio Emilia, Italy - took place on February 3, 2021. The two companies will be legally integrated into the newly founded EMAG technology company, EMAG SU Srl.

SCHERER Feinbau becomes part of the EMAG Group

Founded in 1978 in Mömbris, Lower Franconia, the company stands for the effective and economical production of vertical CNC lathes for chuck and shaft parts, thus ideally complementing the group's machine portfolio.

EMAG acquires CNC-Technik Weiss GmbH

EMAG acquires CNC-Technik Weiss GmbH, headquartered in Neckartailfingen, Germany

20th anniversary

EMAG Leipzig celebrates its 20th anniversary with a big event for all employees and their families.

Axia Best Managed Companies Award

EMAG receives the “Axia Best Managed Companies Award.”

New production facility in Salach

The newly built production facility in Salach, Germany, is inaugurated with a major technology forum on digitalization, electromobility, and modern manufacturing systems.

Grand opening of EMAG Taicang

The technology center in Taicang, China, opens following extensive renovation.

EMAG acquires share in anacision

EMAG invests in the data science company anacision with the aim of working together to develop innovative AI products and solutions for the machinery industry.

EMAG buys a stake in Gefertec

Gefertec, located in Berlin, develops and builds machines in additive manufacturing processes (3D metal printing).

EMAG celebrates construction start for new production and office wing of the EMAG Group in Salach

Grand Opening EMAG Milano

Grand Opening of the EMAG Milano market subsidiary at a new location in Milan

EMAG presents more ground-breaking innovations at EMO 2017. The HLC 150 H by EMAG KOEPFER, the laser welding machine ELC 160 HP by EMAG Automation, the CI 400 by EMAG ECM, and the VMC 450-5 MT by EMAG Leipzig.

EMAG celebrates 150th anniversary with a great party for all employees and their families.

EMAG presents the new turning center VLC 50 TWIN for transmission components of up to 75 mm diameter at the in-house exhibition. The machine has two main spindles in one machining area that are able to process two identical workpieces simultaneously.

EMAG acquires RICHARDON's gear technology

On May 1st, EMAG acquired the entire gear cutting business and related name rights from Richardon. This step continues to enhance the application expertise of the EMAG Group. Richardon is a leader in large-module gear production using gear hobbing and skiving processes. The acquisition perfectly complements the existing technologies in the EMAG Group.

Grand Opening of EMAG Chongqing

The grand opening of EMAG’s new facility in China.

Presentation of the vertical dual-spindle turning center VL 3 DUO for chucked parts at AMB 2016. With its capacity for parts up to 150 mm diameter, the VL 3 DUO is ideal for manufacturing gear wheels and high-output production.

EMAG presents the new VLC 200 GT combined turning/grinding machine for hard machining of chucked parts with a diameter up to 200 mm. The VLC 200 GT uses a combination of various technologies (internal/external grinding, hard turning) for hard machining of chucked parts.

EMAG (Chongqing) Machinery Co., Ltd. is founded

Presentation of the TrackMotion automation system

This system was specially developed for EMAG's modular machines. The compact automation system enables several modular machines to be easily linked into complete production systems.

Presentation of the VM 9

The VM series developed at EMAG Leipzig is ideal for machining large components with complex geometries. The work spindle positioned at the bottom and the 12 position tool turret facilitate difficult machining processes.

Grand Opening of EMAG Jintan

The opening of EMAG's new production plant in China was celebrated with more than 1,000 guests. Jintan is the EMAG Group's central production site for the Asian market.

Development of the VMC 450 MT at EMAG Leipzig

The VMC series of machines is the first in the EMAG Group with work spindles mounted at the bottom. The optimum accessibility of the machining area, combined with the tool magazine with up to 40 tools, is ideal for producing large workpieces with complex geometries.

20 years of WEMA

WEMA Zerbst (plant for CNC machines) celebrates its 20-year anniversary as a central production site of the EMAG Group.

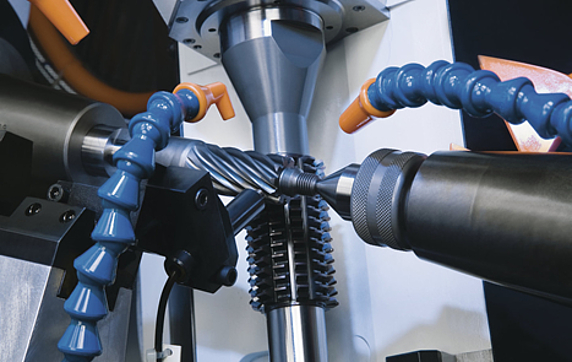

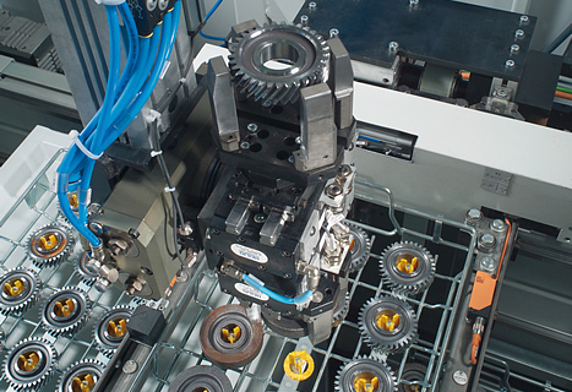

Presentation of the VLC 200 H vertical gear hobbing machine

KOEPFER developed the VLC 200 H vertical pick-up gear hobbing machine on the basis of the modular machine series.

EMAG presents a complete modular machine series at AMB

The modular machine series celebrated its world premiere at AMB in 2013. Along with the vertical turning machines for chucked components, VL 2, VL 4, VL 6, VL 8, the VT 2-4 and VT 4-4 machines for producing shafts were also presented.

Induction Hardening

EMAG eldec develops and manufactures innovative induction hardening machines, generators for induction heating systems as well as inductors.

The heating technology specialists joined the EMAG Group in February 2013.

"Energy Efficiency Award" – the ZF Group honours EMAG’s engagememt.

From the most efficient machine building technology to the cost-saving design of their manufacturing systems, the machine builders from EMAG demonstrated their total know-how in this area, to ensure that they were ideally poised to receive the “Energy Efficiency Award” from ZF.

The results convinced the jury: EMAG’s competition entry was honoured as one of the “Top 5 Projects”.

60 years of EMAG Salach

The plant in Salach, new at the time and today the EMAG Group's headquarters, was acquired in 1952.

Jintan

The construction of the EMAG production in Jintan broke ground. The production base in Jintan will become the most state-of-the-art machine tool manufacturing plant in China, where the Platform No. 2 machine tools for the Chinese market will be built, which have been designed and developed in Germany.

EMAG develops the Platform 2

The machines of the Platform 2 are vertical turning centres that round off the product portfolio of the EMAG Group downward. The platform offers the choice to use a variety of technologies on the various machines covered by it.

EMAG is honoured with the AAM award “Supplier of the Year”.

AAM (American Axle, Mexico) has honoured the EMAG Group with its “Supplier of the Year” award for their outstanding performance in the areas of quality, service and delivery times. Particular mention was made of the superb assistance given during the production run-in. The dedicated engagement of all EMAG service personnel ensured that AAM was able to meet the extensive demands made by their customers. Two further factors – a quick service response and the excellence of the service given – were also of decisive importance in being awarded the honour.

EMAG is honoured with the "Daimler Supplier Award 2010"

Stuttgart, 18.03.2011 – on the occasion of its annual supplier conference – the “Daimler Key Supplier Meeting” – at the Mercedes-Benz subsidiary in Stuttgart, Daimler honours their best suppliers with the “Daimler Supplier Award 2010”. As in previous years, the award goes to 13 sub suppliers covering the various categories of goods and services.

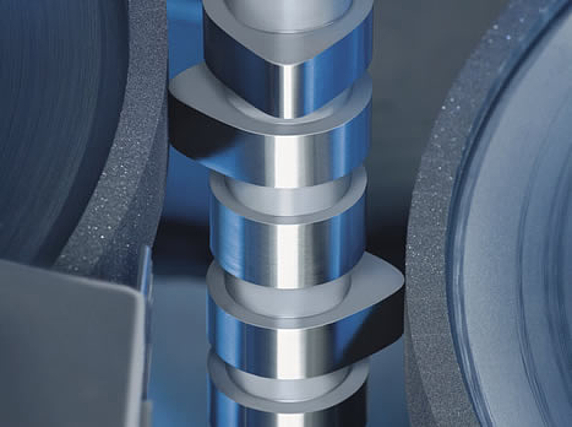

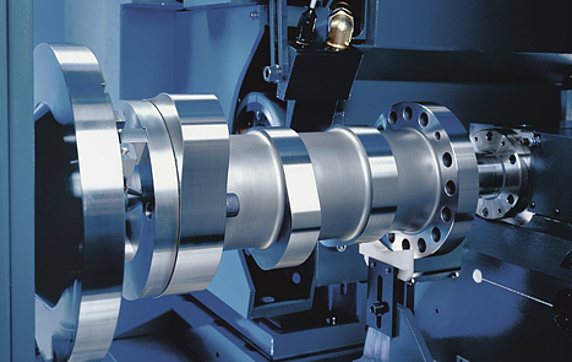

EMAG introduces the complete-machining (grinding) of crankshafts on a single machine, using synchronous support grinding technology.

End 2010 - EMAG achieves a turnover of € 317 million.

At the EMO in Milan EMAG introduces their Platform 250

The Platform 250 consists of three basic machines: The VL 5i, configured as a standard machine, is primarily aimed at the sub-contractor and the turned parts manufacturer. The VSC 250 is a front-operated production machine that can be customised to suit individual machining requirements. And the VLC 250 – a cross-operated vertical manufacturing system with focus on universality – is ideal for multi-technology applications.

EMAG presents their synchronous support grinding technology for the first time.

Synchronous support grinding allows for the application of exceptionally high feedrates, which considerably shortens machining times. The machining time for gearshafts with a number of bearing seats, for instance, has thus been reduced by up to 70%.

EMAG also acquired Dorner GmbH in 2009, which was then renamed to EMAG ECM GmbH.

At the AMB trade fair EMAG introduces the VTC 315 DS for the simultaneous vertical grinding of shafts.

Compared to the traditional method, the machine uses two opposing spindles to 4-axis machine the vertically clamped workpiece. The normal forces cancel each other out, and optimal access to the workpiece is guaranteed. With its HL 1000 EMAG presents an oil hole drilling machine that allows for both soft and hardened crankshafts to be machined.

The VL with Y-axis

The VL is now also available with Y-axis. This allows for the machining of very complex geometries. The Y-axis ensures that off-centre milling and drilling operations no longer require special tools. This noticeably widens the application range of the VL.

EMAG receives the MM Award for Innovation for their VSC 400 WF.

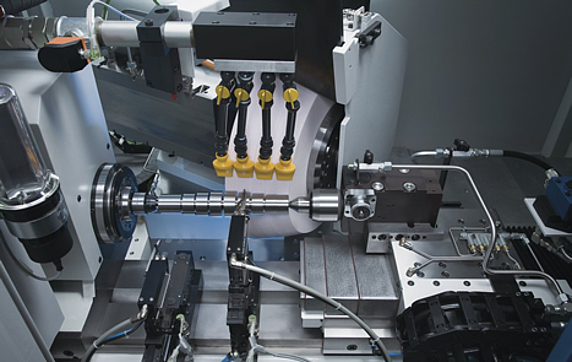

At the EMO exhibition the combination machine VSC 400 WF from EMAG is given the MM Award for Innovation for best lathe work. The VSC 400 WF, developed in cooperation with EMAG’s subsidiary KOEPFER Verzahnungsmaschinen GmbH & Co. KG, combines the technologies Turning and Gear Hobbing on a single machine. This makes it possible to manufacture large quantities of gears of the highest quality at minimum cost. NAXOS-UNION introduce their PM 2 Grinder for small crankshafts of up to 500 mm length at the EMO.

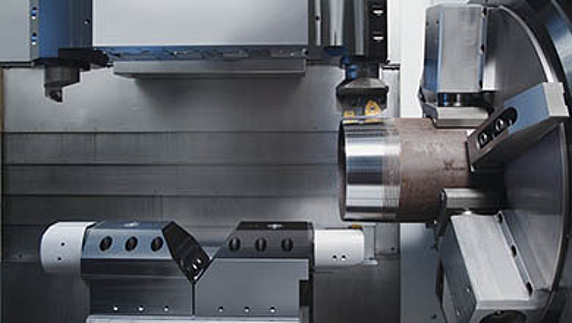

Multi-technology machining of shafts

In the wake of the success achieved with the VSC DS series (turning and grinding of chucked components) EMAG introduces a machine for the multi-technology machining of shaft-type components. With the transfer of the technology combination turning+grinding to the VTC series of machines EMAG becomes the first to offer all end machining processes for shaft-type components on a vertical machine: CBN grinding, hard turning and/or scroll-free turning.

EMAG for the best manufacturing solution

With machines for chucked, shaft-type and cubic components the EMAG Group now offers optimal manufacturing solutions for almost every conceivable customer requirement. The product range covers everything from standard to customised special application machines. It is further complemented by the VSC 400 MODULAR, a series of machines that close the gap between standard and customised solution.

Introduction of the HG 2

With its HG 2 External Cylindrical Grinder EMAG KARSTENS introduces an innovative, highly flexible concept for the precision machining of shaft-type components.

Development of the PM 460

NAXOS-UNION presents the PM 460 Grinder for the machining of crankshafts up to a weight of 6 metric tons and a length of 6 m. The highest degree of contour accuracy and surface finish are achieved using the pin chasing method that NAXOS-UNION developed and in which the company is worldwide leader.

The 1000th VL machine

EMAG delivers the 1000th VL. This makes the VL series one of the most successful products of the EMAG Group.

EMAG Holding GmbH assumes control of the EMAG Group

September – At the EMO Hanover the complete product range of the EMAG Group is presented

In addition to turning und grinding machines the new combined vertical pick-up Turning and Machining Center VLC 400 MT; from EMAG KOEPFER: the new combined Turning and Hobbing Center VSC 400 DUO WF and the new VSC 400 PH gear profiling system for the Power Honing of hardened gears – both vertical pick-up machines with integrated automated workpiece handling.

Autumn – EMAG INDIA Ltd., Bangalore, establishes branch offices in Delhi, Pune and Chennai to offer a better service for existing and new customers.

End 2005 – The EMAG Group employs approx. 2.000 staff worldwide in the service of its customers. This number is augmented by 200 trainees at EMAG's German locations.

The German gear hobbing specialist KOEPFER, Furtwangen, becomes part of the EMAG Group.

With this acquisition EMAG takes yet another gigantic step towards becoming the supplier of complete process streams now also in the field of gear hobbing.

The EMAG Group expands

Further regional sales offices and EMAG market companies take up their duties in Cologne, Austria and Turkey.

EMAG Machine Tools (Taicang) Co. Ltd. is founded (today EMAG (China) Machinery Co., Ltd. Taicang Branch)

EMAG in Korea

To provide an efficient service for its Korean customers and to be able to canvass the local market more intensively, EMAG establishes the market company EMAG KOREA.

EMAG in Denmark

The sales office EMAG Denmark, a regional branch of the market company EMAG Salach, takes up its duties.

Restructuring of the EMAG group

Spin-off of EMAG REINECKER KARSTENS Technologie GmbH, Salach, for the optimal utilisation of the great variety of technologies now available for process stream production. Spin-off of the market company EMAG Salach, to allow for even greater efficiency in the service for EMAG customers in south-western Germany.

EMAG introduces LaserCell

At EMO in Milan, EMAG presents LaserCell, a completely new kind of production machinery for joining and laser welding multiple different parts to form assemblies.

EMAG in Japan

The joint venture company EMAG TAKAMAZ is founded in Japan. Japanese engineers now look after their home market and service the EMAG machines already installed in Japan.

EMAG in Mexico

The market company EMAG MEXICO is founded to ensure that regional EMAG experts can provide an efficient service for existing and prospective customers.

EMAG LASER TECH is founded in Salach

This represents an important step forward in providing EMAG customers with further processes, together with the application of laser technology, for the manufacture of ready-to-install assemblies. The market company EMAG CHINA, Shanghai, is founded with the objective to intensively work the Chinese market and to use its experienced, highly qualified local staff in the service of its many customers.

NAXOS-UNION becomes part of the EMAG Group

With the Frankfurt-based NAXOS-UNION, leading German manufacturer of crankshaft grinders, the EMAG Group expands its technological competence also in the machining of this range of workpieces.

EMAG acquires HEILIG AUTOMATION

HEILIG AUTOMATION, Heubach, Germany, becomes part of the EMAG Group and its centre of excellence for automation equipment.

KOPP becomes part of the EMAG Group

KOPP Werkzeugmaschinen, Neu-Ulm, a German specialist in the milling and grinding of high precision cams and camshafts, becomes part of the EMAG Group.

EMAG in Italy

The EMAG Group takes over its former agency in Italy and develops it into its market company ZETA EMAG.

EMAG Leipzig machine factory is founded

PITTLER-TORNOS is taken over and incorporated into EMAG Leipzig Maschinenfabrik, which expands to become today's market company for the northern and eastern states of Germany.

Since 2005, EMAG Leipzig has also been the technology center for the machining of tubes and couplings.

REINECKER becomes part of the EMAG Group

The German grinding machine manufacturer REINECKER, Ulm, specialist in internal cylindrical precision grinding of chucked components, becomes part of the EMAG Group.

EMAG in India

EMAG INDIA in Bangalore is founded and takes up its duties in the service of the customers in this growing market.

The VSC 250 DDS is introduced

Introduction of the world's first combined Turning and Grinding Center (also based on the VSC design) with the new GRIND-FINISHING technology.

KARSTENS becomes part of the EMAG Group

Incorporation into the EMAG Group of the German grinding machine manufacturer KARSTENS, a specialist in the external cylindrical grinding of shaft-type components.

Machine tool factory Zerbst becomes part of the EMAG Group

Acquisition of WEMA Werkzeugmaschinenfabrik Zerbst, Germany, and its development into the central manufacturing facility of the EMAG Group.

Introduction of the VSC, the world's first vertical turning center with pick-up spindle.

Development of the VSC machines into multifunctional/multi-tasking Production Centers.

EMAG in Russia

The KP EMAG joint venture in Moscow is founded; now renamed EMAG OOO, this member of the EMAG Group handles all customers in Russia and the other CIS countries.

EMAG in USA

Founding of a subsidiary in the USA. Today, EMAG L.L.C. operates from Farmington Hills, Michigan, taking care of the customers in North America and Canada.

EMAG growth

Worldwide distribution of highly automated CNC turning cells and manufacturing systems for, in particular, the automotive industry and the oil industry.

EMAG in France

Start of the co-operation with NODIER, France. Today, NODIER EMAG is part of the EMAG Group and market company for the customers in France.

The first modular series

Introduction of a series of highly efficient, program-controlled, modular turning automatics. In the 70s the company enters the field of endworking.

EMAG is re-established

Re-established in Eislingen, Baden-Württemberg, manufacturing lathes and special purpose machines. In 1969 move to Salach, today's Group headquarters.

Founded in Bautzen, Saxony, as an iron foundry and engineering works.