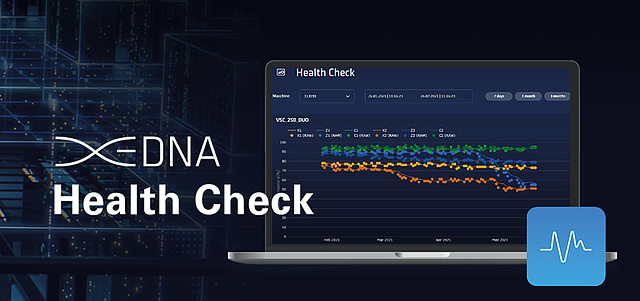

EDNA Health Check: Higher availability through predictive maintenance and lower service costs

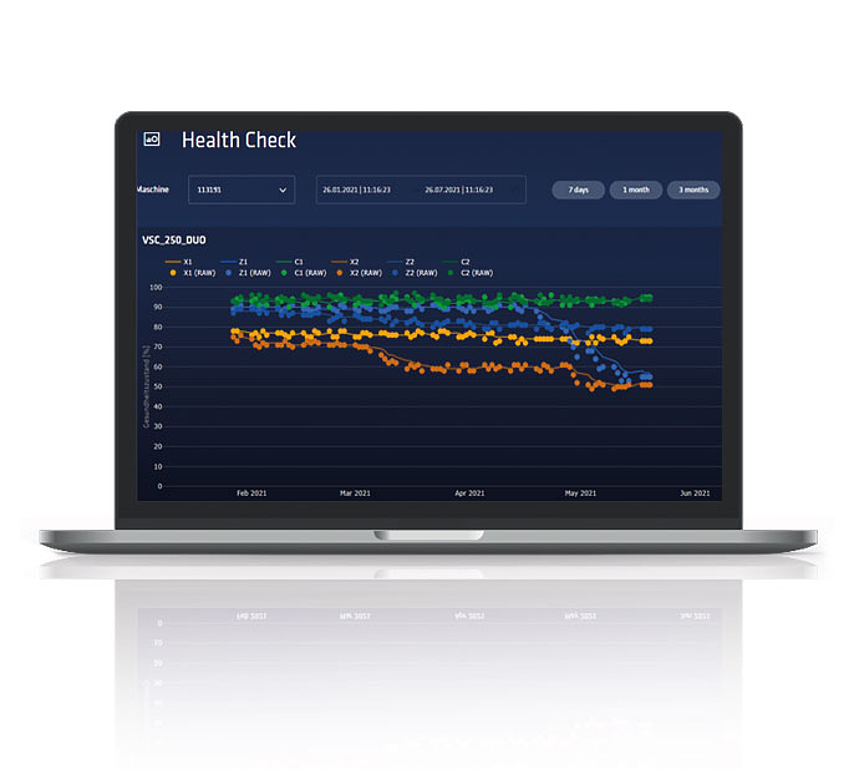

EDNA Health Check assesses the condition of your machine by analyzing regular vibration measurements. The combination of EMAG’s expertise and machine learning provides an in-depth look at the state of wear of different machine components.

Health Check: Systematic servicing for more productivity

With the Health Check, EMAG supports the health assessment of machines - a valuable early warning system for servicing. The special feature: The experience of experts is mapped in the analysis software. The entire solution scores highly in terms of usability. The result of the check is displayed within a few minutes.

This is the technical basis

1. Automated: With the full version "Health Check", a measurement run is started automatically at regular intervals in the machine, whereby the vibrations of the machine are recorded with the aid of 3D acceleration sensors and transferred to the EMAG Health Check analysis.

2. Analyzed: The user reads the health values in an app. They can also analyze the data in a report.

3. Valuable: Trends in the health values serve users as a valuable early warning system for servicing, as the interpreted vibrations can indicate bearing play and damage, spindle vibrations or other interference frequencies, for example.

Advantages

- Information on the health trend of the machine

- Early warning system for servicing

- Evaluation of the data by EMAG experts

- Automatic or manually triggered data transfer

Further solutions for every application

Alternatively, a semi-automated process is available to the customer with an already set up measurement run called Health Check Lite. Here, users download the (manually triggered) measurement run results and then send them to EMAG by e-mail.

Who benefits from this approach?

Users receive precise and up-to-date information on the health trend of their machine. In addition, the EMAG service department involved can be informed automatically if the health values of a machine deteriorate. The experts can then take a detailed look at the measurements and decide whether further steps are necessary.

Contact IoT

Do you have questions or need more detailed information? Please contact us!

iot@emag.com