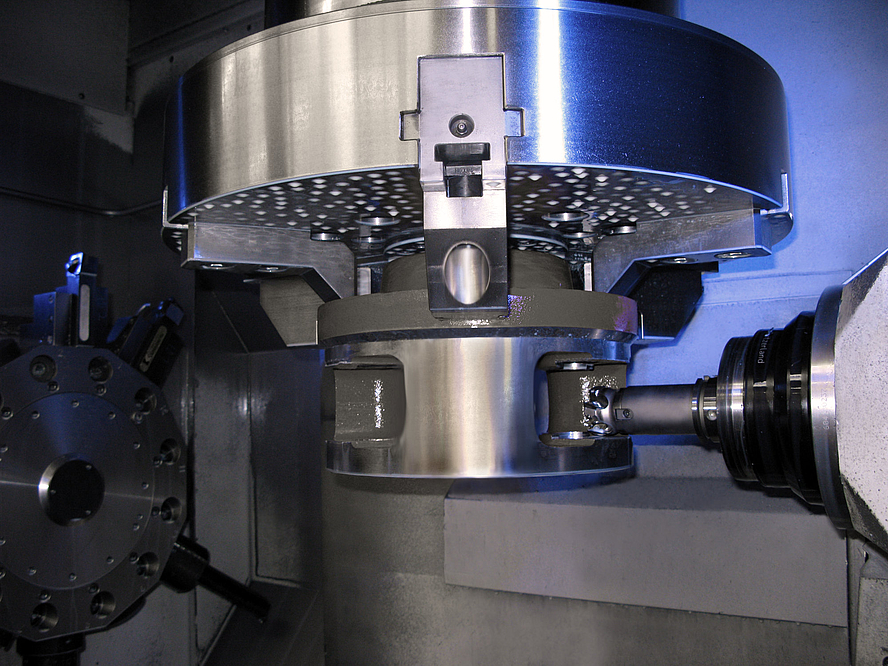

The azimuth drive: manufacturing solutions for the wind power industry

The boom in the wind power industry is showing no sign of stopping. All around the world, renewable energies are a popular investment vehicle and wind turbines are playing an increasingly important role. Accordingly, the demand for drives for building wind turbines is also growing. This is a sector in which EMAG is already represented in the market, with a variety of manufacturing solutions. The focus lies on the production of azimuth drives for swiveling the nacelle as well as pitch drives for adjusting the angles of the individual rotors.

Manufacturing of components for the azimuth drive/wind direction tracking system on EMAG machines

Line concepts for every batch size

Line concept | Envelope | 2 x VL 8 - Flexible solution for small batches

The production line with two VL 8 machines optimally combines flexibility and efficiency. Parts can be handled between the two machines either manually by the operator or automatically using TrackMotion. The machining of the shell is carried out in two operations, consisting of precision turning and drilling.

The advantages:

- Flexible production with minimal footprint

- Low capital investments

- Suitable for smaller series and varying production batches

Advantages Azimuth drive

- Technology, automation, and process development come from a single source – with the focus always on short delivery times and a rapid start to production.

- All machines and the automation system are perfectly coordinated.

- Simple automation systems, optimized interfaces, and short transport distances create rapid production processes.

- High machining quality

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Drilling is one of the oldest production methods and has been used by humans since the Stone Age.

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process…

Machines for your requirements

(1) machines found