ECM / PECM Machines

PO 100 SF

- Machining area: mm 750 x 600 x 360

- Clamping surface: mm 370 x 450

- Generator capacity: A (DC) 2 x 2.500 – 5.000

The Cost-Effective Solution for Complex Turbine-Blade Machining with PECM Technology.

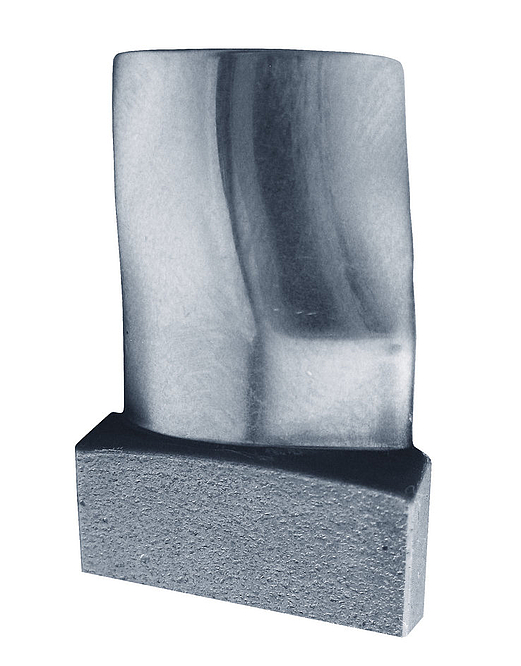

The machine construction technology used for producing turbine components is developed at EMAG ECM GmbH – the technology center for Electro-Chemical Machining (ECM) within the EMAG Group. The compact PO 100 SF model is configured for the machining of turbine blades.

PECM Technology for "Soft" Turbine-Blade Machining

EMAG's PECM technology is used on the PO 100 SF.

This technology is a targeted refinement of the ECM process, where the gap between the workpiece and the tool through which the electrolyte solution flows is especially narrow. Simultaneously, the feed is superimposed by a mechanical oscillation movement. The two factors together ensure an even more effective, precise removal of the material – which generates financial benefits as well. Expensive milling tools are no longer required, and thermal influences do not impact the turbine blades. This and perfect surfaces with low roughness values produced by the PECM process ensure that post-processing is practically eliminated.

Advantages PO 100 SF

- MINERALIT® polymer concrete machine base

- Two Oscillators with zero backlash

- Y-axis

- Hydraulic zero point clamping system

- Machine control unit SIEMENS SINUMERIK 840D sl

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Electro-Chemical Machining (ECM) is the generic term for a variety of electro-chemical processes. ECM is used to machine workpieces through the anodic…

The use of electro-chemical metal removal processes guarantees surfaces of the highest quality - even on filigreed components. To achieve even greater…

Technical Data

Machining area

750 x 600 x 360 mm

Clamping surface

370 x 450 mm

Generator capacity

2 x 2.500 – 5.000 A (DC)

| Machining area | mm | 750 x 600 x 360 |

| Clamping surface | mm | 370 x 450 |