Sprocket Production with the Hard-turn and Grinding Combination Machine

The combination of different processes within a single machine and a single setup offers enormous savings potential in terms of cycle times. With the machining of chucked components up to 100 mm in diameter, including for example, gears, cam rings, sprockets, pump rings and individual cams, massive time savings can be realized while still achieving top-quality machining results.

Sprockets are especially suitable for machining on a VLC 100 GT.

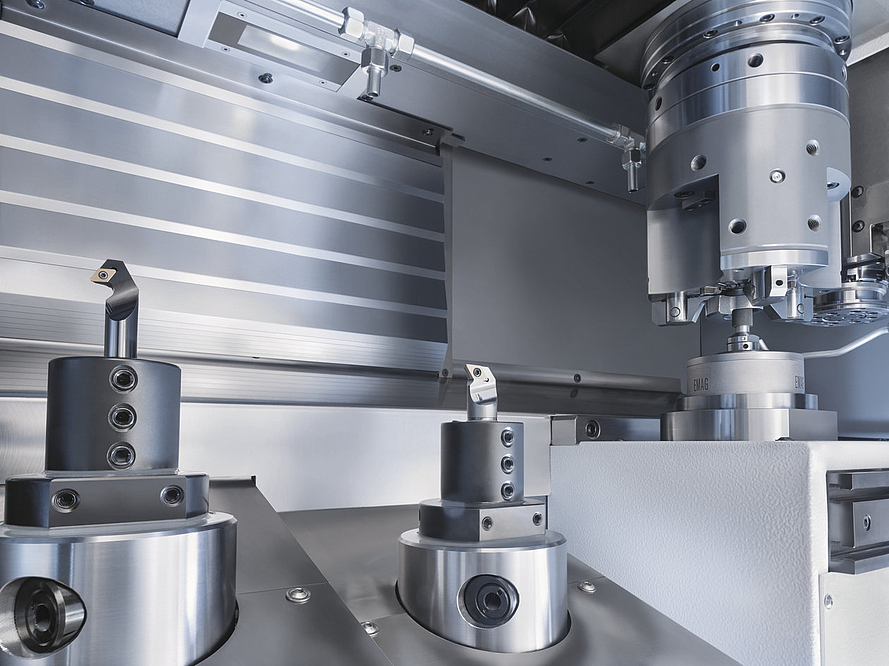

A specific example makes the quality of the VLC 100 GT crystal clear. The benefits of combination machining are immediately visible when one considers sprocket production. After the machine is automatically loaded by means of the pick-up spindle, initial machining begins with the integrated internal grinding spindle. Drilling the sprocket wheel allows minimal allowance and is finish-ground with CBN. The end faces of the sprocket are machined with the two steel block holders also located in the production area. Employing hard turning technology for machining not only facilitates very short production times, it also requires no post-production step. The machining quality of the sprocket is then checked using a probe located between the production area and the loading station. The high performance of the vertical turning and grinding center is underscored by the fact that the entire process takes less than 50 seconds to complete.

With the VLC 100 GT, EMAG has created a system for the combination machining of sprockets that delivers impressive performance despite its compact construction. Loading by means of the pick-up spindle and use of cutting-edge grinding technology in combination with turning operations, in brief: the entire machine is designed for performance, as demonstrated by the sprocket example above. Whether in series production or as a standalone version, the VLC 100 GT from EMAG is a vertical turning and grinding center for a wide range of applications.

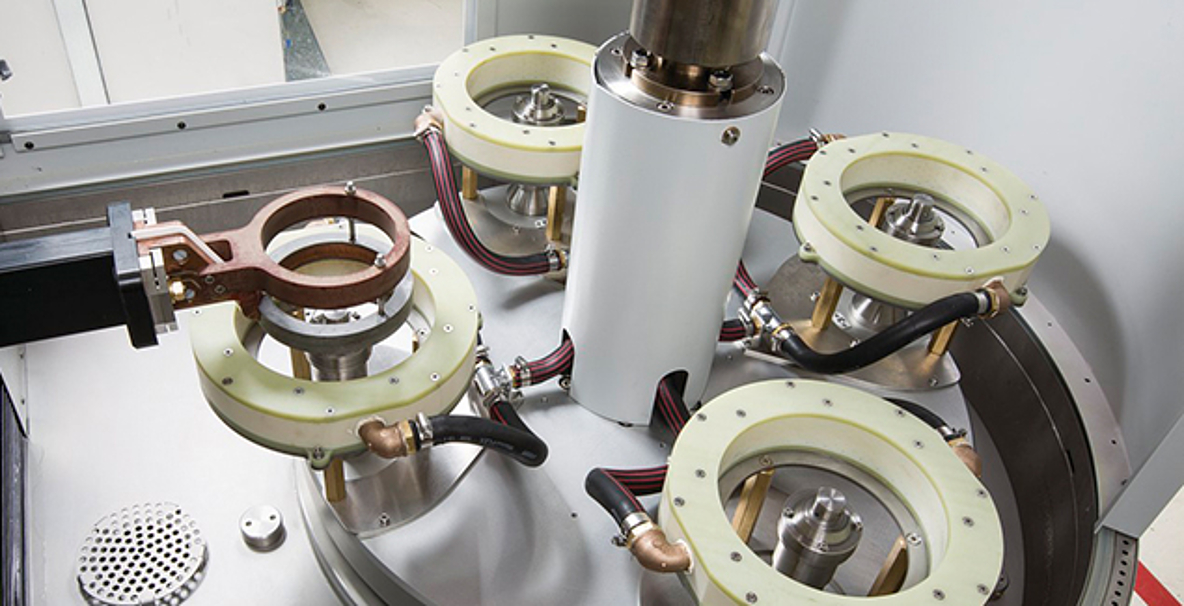

Induction hardening sintered sprockets on the MIND 750 hardening machine

Extremely fast cycle times and high output volumes is the focus of the MIND 750 hardening machine with an annealing module for the induction hardening of sintered sprockets. The fully automated system allows two sprockets to undergo induction hardening at the same time using a twin inductor. With an eldec high-frequency generator is also possible to reduce heating times to under one second. The high precision application of the energy for induction hardening, and the subsequent joint annealing and cooling process, enable the sintered sprockets to achieve the required strength.

The MIND 750 hardening machine used for the induction hardening process features high flexibility, thanks to its modular design, and maximum precision on all movement axes and in the control of energy volumes. Whether a twin inductor, an annealing module or, as here, a complex robot is used for the induction hardening process depends entirely on the requirements of the production planner.

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

The combination of a number of processes – such as hard turning and grinding – on a single machine, allows for the exploitation of considerable…

Machines for your requirements

(1) machines found