Deburring and Chamfering of Gears, Gear Shafts and Gears with Synchronizing Wheel

Deburring is an essential procedure in many production processes - after all, burrs that are not removed could break off later and damage bearings or gears in the gear unit. In addition, burrs (that are still present) cause grinding tools to wear more quickly in the subsequent process, for example.

Short Cycle Times Always “Designed into“ the Deburring

During the mechanical machining of metal, undesired burrs frequently occur. These can be removed using special tools. In addition, the component is given a chamfer.

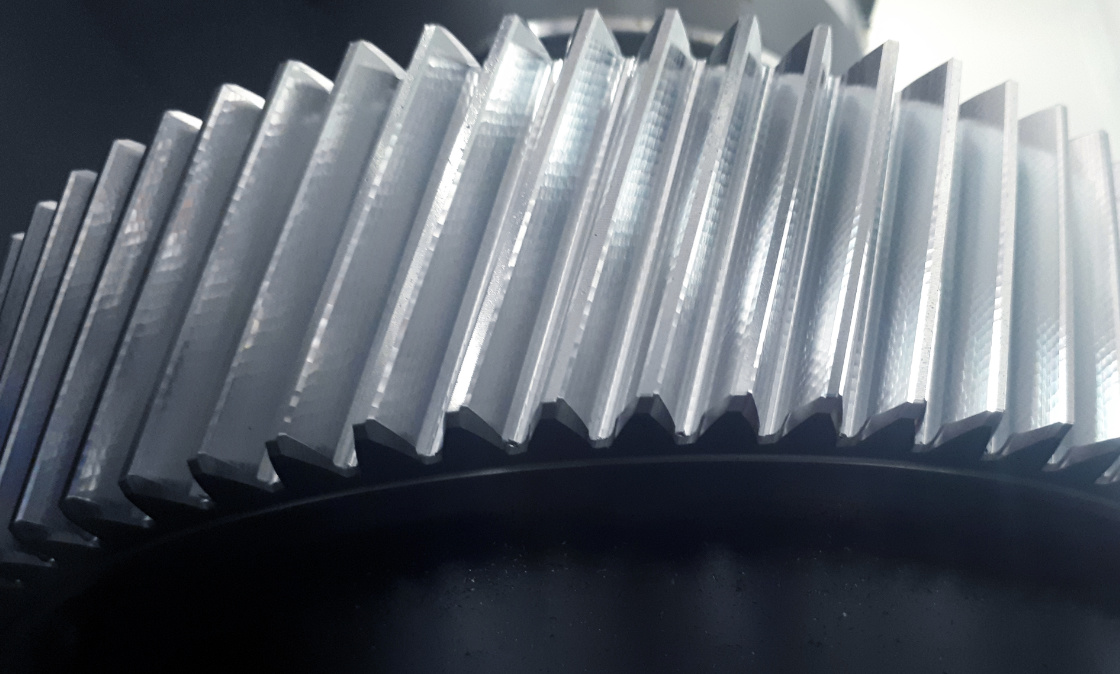

Flow-turning deburring

Flow-turning deburring on the SCT 3 is a forming process. With this process, the chamfer is formed using a flow-turning deburring tool and the burr on the face is removed using secondary blades. Using a combined tool, the toothing is smoothed at the same time so that there is no material throw-up in the flank line. Due to the simultaneous machining of both gear sides, this procedure is highly productive and therefore ideally suited for mass production.

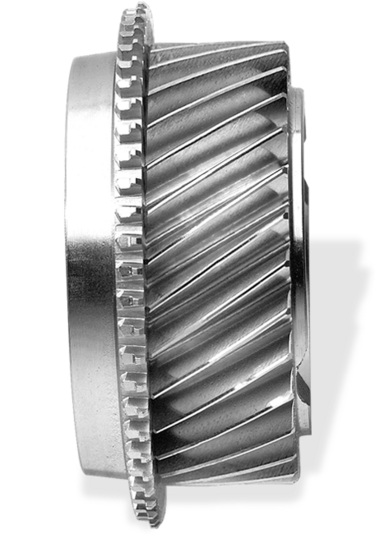

Deburring with grinding wheels

For this, a small grinding wheel is positioned on each side of the gearing and pressed against the rotating workpiece by spring force. This method is suitable in the event of arge numbers of component variants.

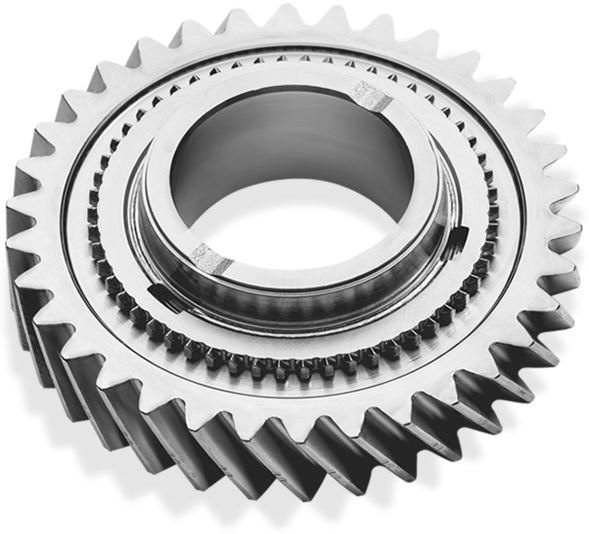

Deburring with hob or side milling cutter

We only offer this procedure as a combination solution on the hobbing machines in the 90° position of the 4-station ring loader. Here a milling cutter is used to deburr and chamfer the right and left sides of the gear without interrupting the main machining operation.

Advantages Deburring

- Indispensable: Deburring prevents premature wear and damage.

- Fast: The combination of deburring and chamfering results in extremely short cycle times.

- Holistic: The secondary burrs of the chamfer are also removed.

Workpieces