Press

06/30/2025 - Oliver Hagenlocher - Press

VLC 450 DG from EMAG: Perfecting the coated car brake disc in the grinding processThe car brake disc of the future is coated - the only way to meet the stricter particulate matter limits of the Euro 7 standard. The braking surface is also protected against corrosion and wear. But which machining process can guarantee that this quality can be achieved reliably in large quantities?…

05/28/2025 - Oliver Hagenlocher - Press

Comprehensive machining expertise: EMAG VL lathes in the PENN GmbH production chainThe increasing complexity of requirements in metal processing and international cost pressure pose particular challenges for manufacturing companies in high-wage countries. The Austrian company PENN GmbH has established itself as an internationally active metal processor through a high level of…

04/29/2025 - Oliver Hagenlocher - Press

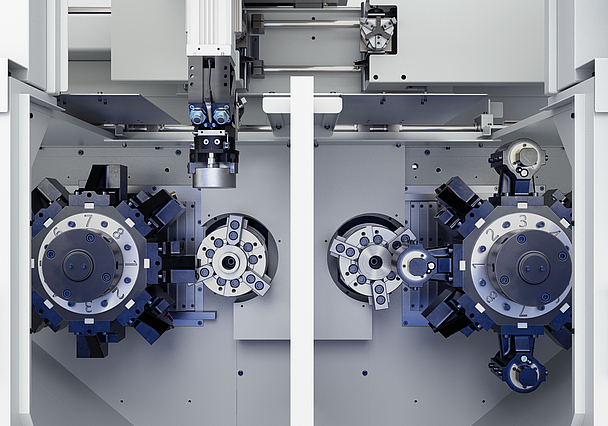

MSC 5 DUO: Front-loading CNC turning center for economical soft turningIn today's world, manufacturing companies are facing major challenges: increasing cost pressure, a shortage of skilled workers and rising energy costs. This combination requires machine tools that generate more output with less manpower and are energy-efficient at the same time. The MSC 5 DUO from…

03/07/2025 - Oliver Hagenlocher - Press

Hard coating of brake discs using laser deposition welding: Efficient coating of brake discs - and compliance with EURO 7 regulationsThe EURO 7 standard will immensely change the automotive industry: for the first time, not only emissions from combustion engines will be regulated, but also the abrasion of brakes, among other things. The initial conclusion is that the particulate matter produced by many models must be…

11/19/2024 - Oliver Hagenlocher - Customer Stories

Precision manufacturing of high performance transmission components on vertical pick-up turning machinesZoerkler Gears GmbH & Co KG, a renowned manufacturer of high-precision drive systems for the aerospace and automotive industries, is using the VL 6 vertical pick-up turning machine from EMAG for machining high-precision transmission components. This strategic investment underlines Zoerkler's…

09/09/2024 - Oliver Hagenlocher - Press

The new VST 50 from EMAG: A new ball pin leaves the machine every seven secondsWhether in the steering system or in the chassis - ball joints are indispensable in our cars. They not only act as a kind of pivot point between different elements, but are also usually in constant motion and exposed to high physical loads. In this context, ball pins and ball sleeves are among the…

07/09/2024 - Oliver Hagenlocher - Customer Stories

MR Components relies on intelligent automation with EMAG machines and benefits from unmanned production in the evening hoursMR Components, a medium-sized company from Grigno, Italy, has significantly increased its production capacity and simultaneously improved quality by introducing intelligent automation with EMAG machines. The company, which specializes in the production of parts for differential and planetary gears,…