Stampa

09/09/2024 - Oliver Hagenlocher - Stampa

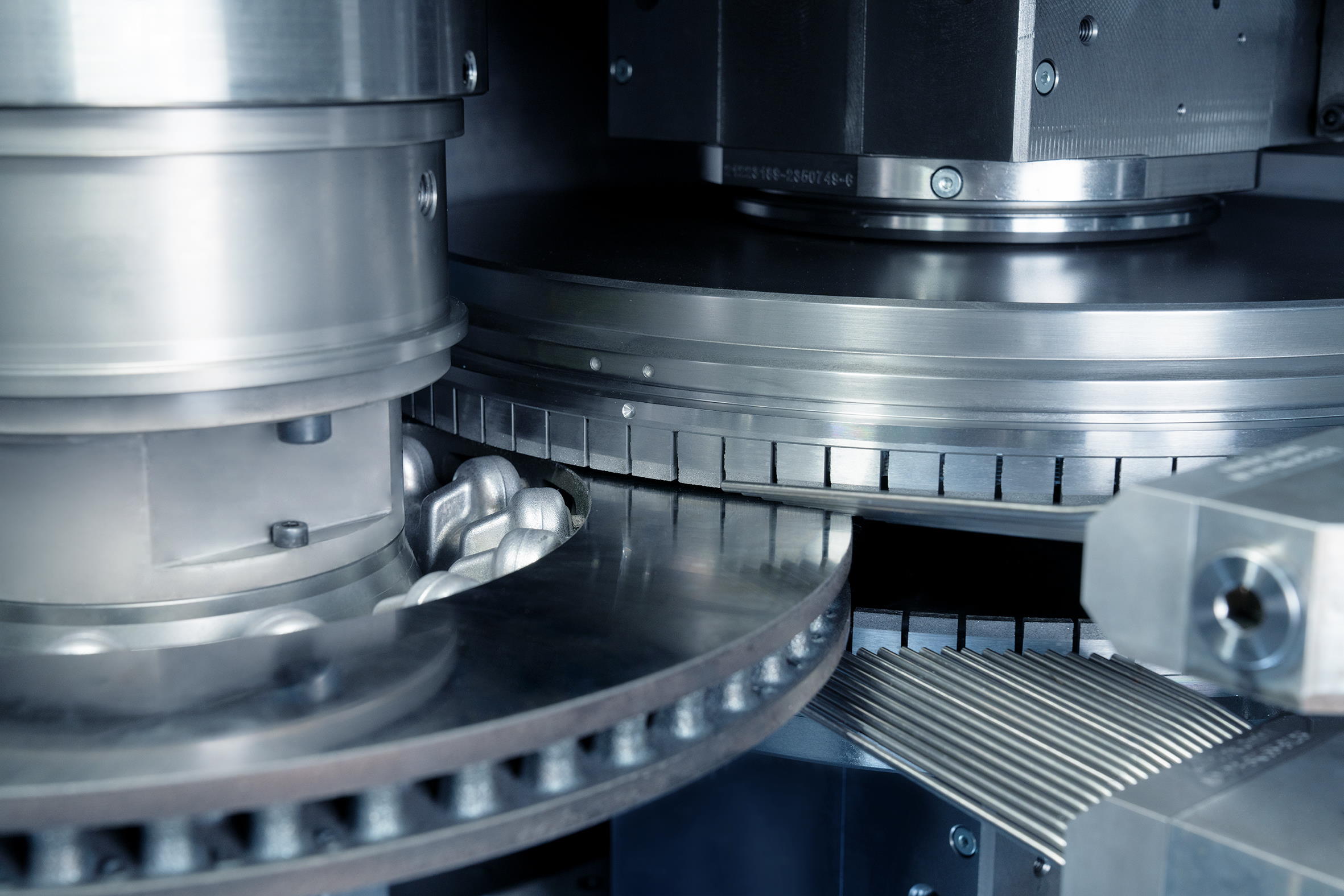

The new VST 50 from EMAG: A new ball pin leaves the machine every seven secondsWhether in the steering system or in the chassis - ball joints are indispensable in our cars. They not only act as a kind of pivot point between different elements, but are also usually in constant motion and exposed to high physical loads. In this context, ball pins and ball sleeves are among the…

09/07/2024 - Oliver Hagenlocher - Storie di successo dei clienti

MR Components si affida all’automazione intelligente di EMAG per trarre il massimo vantaggio anche nella produzione non presidiataA Grigno, nelle Dolomiti del Trentino si trova MR Components, un’azienda che ha saputo sfruttare al massimo i vantaggi offerti dalla produzione automatizzata delle macchine EMAG, aumentando la propria capacità produttiva e specializzandosi nella lavorazione completa di scatole differenziali e corone…

03/05/2024 - Oliver Hagenlocher - Stampa

New opening of the EMAG plant in Querétaro, MexicoThe EMAG Group opened its new plant in the San Isidro Business Park in Querétaro, Mexico, on April 25, 2024. This step is another milestone in the company's 20-year success story in the Mexican market and underscores EMAG's commitment to the region.

25/04/2024 - Oliver Hagenlocher - Stampa

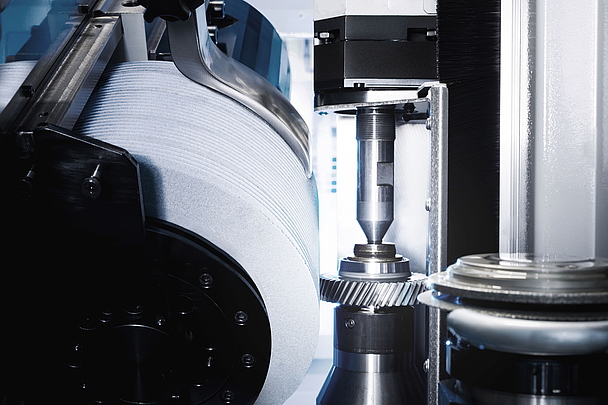

EMAG at the GrindingHub 2024 – Grinding technology for the low-emission mobility of the futureGrinding is a key technology for the resource-saving and low-emission mobility of the future. Examples of this include electric drives, which place the highest demands on the precision and surface properties of transmissions and engine components, or brake discs with reduced fine dust and hard…

10/04/2024 - Oliver Hagenlocher - Stampa

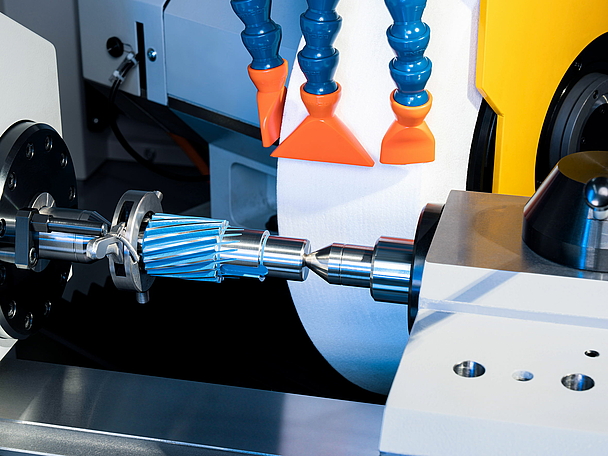

WPG 7 CNC di EMAG Weiss: Garantisce processi di smerigliatura esterna rapidi nello spazio più piccoloIn molti settori di applicazione, l'utilizzo di rettificatrici cilindriche universali sovradimensionate per la lavorazione esterna di componenti più piccoli è antieconomico: si perde molto spazio e non si sfrutta affatto la funzionalità. Con la nuova rettificatrice esterna WPG 7 CNC, EMAG Weiss sta…

13/03/2024 - Oliver Hagenlocher - Stampa

EMAG is working on "green manufacturing": Pulling out all the stops for greater energy efficiencyHow important is the topic of "climate-neutral production" for industry at this moment? A recent survey conducted by the German Engineering Federation (VDMA) among its member companies provided an impressive answer. According to the survey, more than three quarters of companies have set their own…

27/02/2024 - Oliver Hagenlocher - Storie di successo dei clienti

Bharat Forge Daun si affida a EMAG: Perfezionamento del processo di lavorazione dell'alloggiamento dello statore in tutte le sue partiComponenti insolitamente sofisticati e materiali ad alta resistenza per applicazioni high-tech: presso Bharat Forge Daun, ad esempio, si producono alloggiamenti per statori per l'elettromobilità, con gli specialisti che garantiscono sempre una qualità nell'ordine del micrometro. Al centro di tutto:…

02/02/2024 - Oliver Hagenlocher - Stampa

EMAG Middle East Announces Opening of Office with International Free Zone in DubaiThe EMAG Group has officially opened its new sales company EMAG Middle East with the International Free Zone Authority (IFZA) in Dubai. With this expansion, the company is taking an important step into the fast-growing markets of Central Asia and the Middle East.

09/01/2024 - Oliver Hagenlocher - Stampa

Soluzioni di rettifica di EMAG SU: Finitura superficiale estrema per la mobilità elettricaParticolare precisione e affidabilità dei processi hanno caratterizzato l'ingegneria automobilistica per molti decenni. Con l'affermarsi della mobilità elettrica, tuttavia, queste esigenze stanno aumentando ancora una volta, perché molti componenti dei motori elettrici devono essere prodotti in modo…