Saldatrici laser

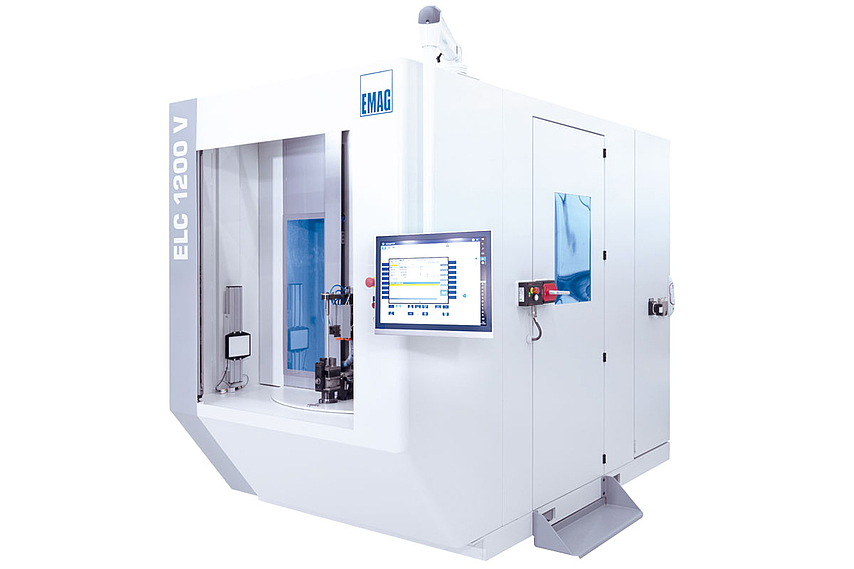

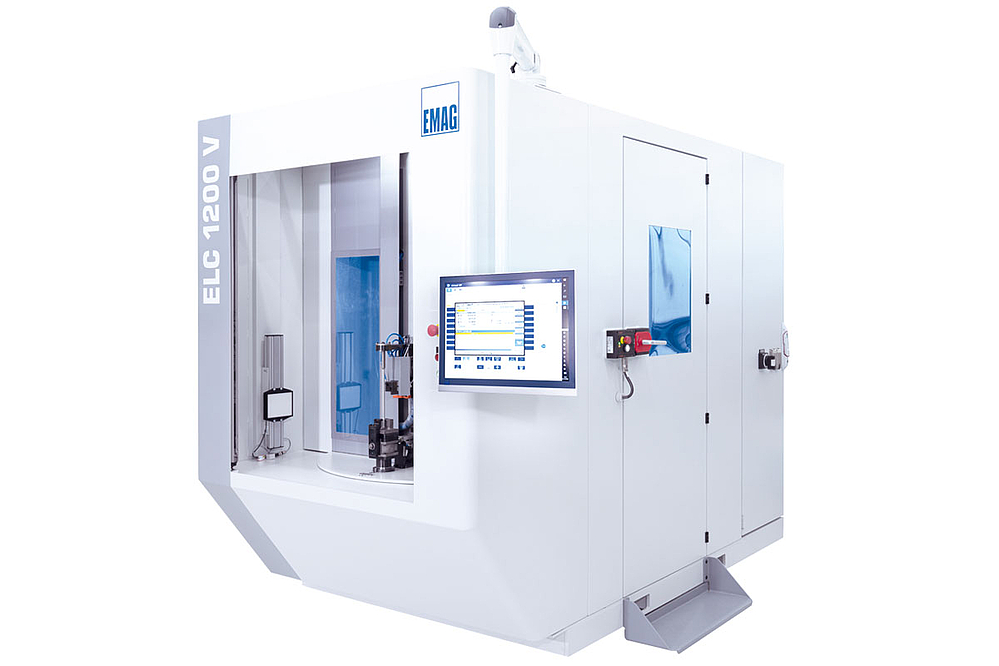

ELC 1200 V

- Ø max. pezzo: 300 mm | 12 in

- Lunghezza max. pezzo: 1,200 mm | 47 in

- Workpiece length, min.: 50 mm | 2 in

ELC 1200 V Vertical Laser Processing Machine for Shaft Components

The vertical laser processing machine ELC 1200 V is designed for workpieces up to 1200 mm in length and impresses with its fast processing, a small footprint and extreme ease of operation. In addition to laser welding, other laser processes such as laser cleaning and laser hardening can be used on this new machine.

ELC 1200 V Vertical Laser Processing Machine with EDNA HMI for easiest operation

The ELC 1200 V offers maximum flexibility in production. The 3-axis laser lens is NC-controlled and can be configured to meet a wide variety of individual requirements.

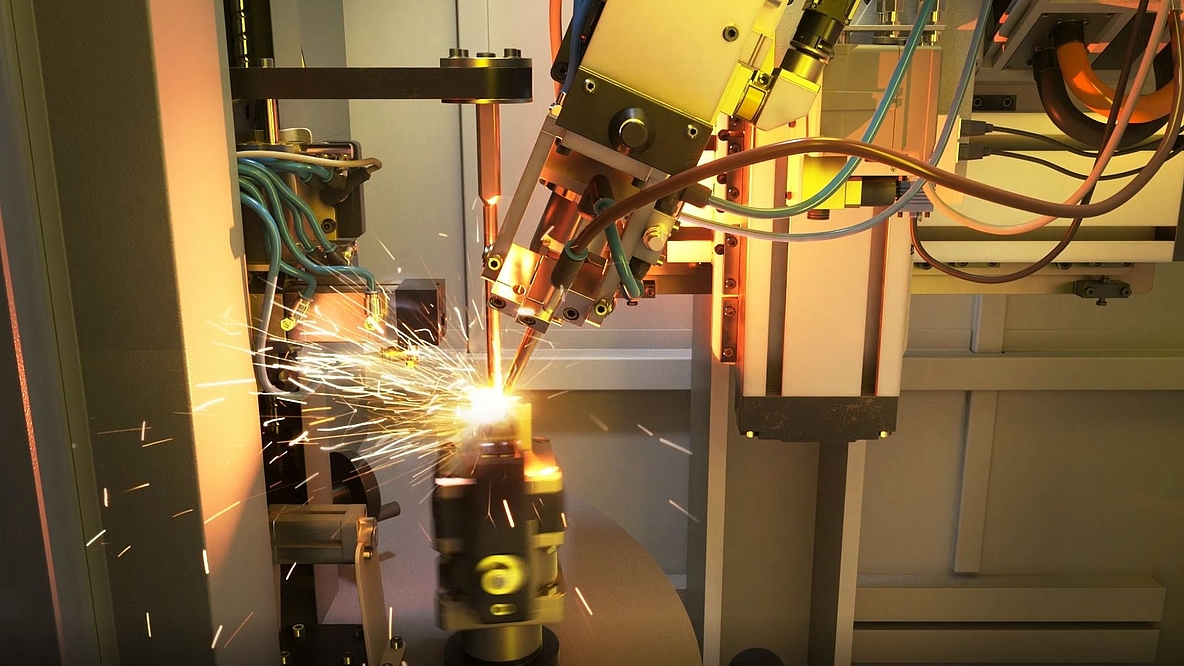

In combination with the NC-controlled C-axis of the clamping device, the welding lens can also produce interpolated welds. This means that, for example, a quick conversion for laser welding of families of parts can be implemented without any problems. The clamping system is, of course, just as flexible as the laser lens.

Highlights:

- Designed for simple workpieces/processes

- Vertical workpiece clamping

- Workpiece lengths between 50 mm and 1,200 mm

- One or more welds

- Flexible due to NC-controlled axes

- Cycle times start at approx. 6 seconds

- Loading and unloading during machining

- Simplified user interface EMAG DNA panel

EMAG DNA Panel

The key highlight, however, is the graphical user interface with which the machine can be controlled and programmed.

HMI Advantages with the ELC 1200 V:

- HMI specially developed and optimized for laser applications

- Easy-to-learn operation through graphical user guidance

- Easy set-up of new workpieces using “Teach in”

- SIEMENS CNC screen still fully usable

- IoT interface for data-optimized production (connection to IPC and other EDNA software)

- Multi-device – data can be called up on mobile devices

More about EDNA HMI

Vantaggi ELC 1200 V

- The vertical machine requires only 4.3 square meters of floor space.

- The new EDNA HMI makes it easier to operate and program the ELC 1200 V.

- The loading and unloading by rotary indexing table takes place parallel to the machining time. The machine practically never stands still.

- The laser lens has an X-axis and a Z-axis, as well as an additional B-axis for rotating the laser lens.

- The ELC 1200 V vertical laser processing machine is designed for workpieces with a length of 50 to 1,200 millimeters.

- The machine can be operated both manually and fully automatically.

Tecnologie

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Laser cleaning is a fast and space-saving process that can replace conventional washing machines in many applications. One of its main strengths is…

Laser welding is a precondition for compact, weight-optimised components and thus for energy- efficient vehicles. Adjustable doses of concentrated…

Industry 4.0

Dati tecnici

Ø max. pezzo

300 mm

12 in

Lunghezza max. pezzo

1,200 mm

47 in

Workpiece length, min.

50 mm

2 in

| Ø max. pezzo |

mm

in |

300

12 |

| Lunghezza max. pezzo |

mm

in |

1,200

47 |

| Workpiece length, min. |

mm

in |

50

2 |

| Peso pezzo max |

kg

lb |

10

22 |