新闻中心

09/09/2024 - Oliver Hagenlocher - 新闻中心

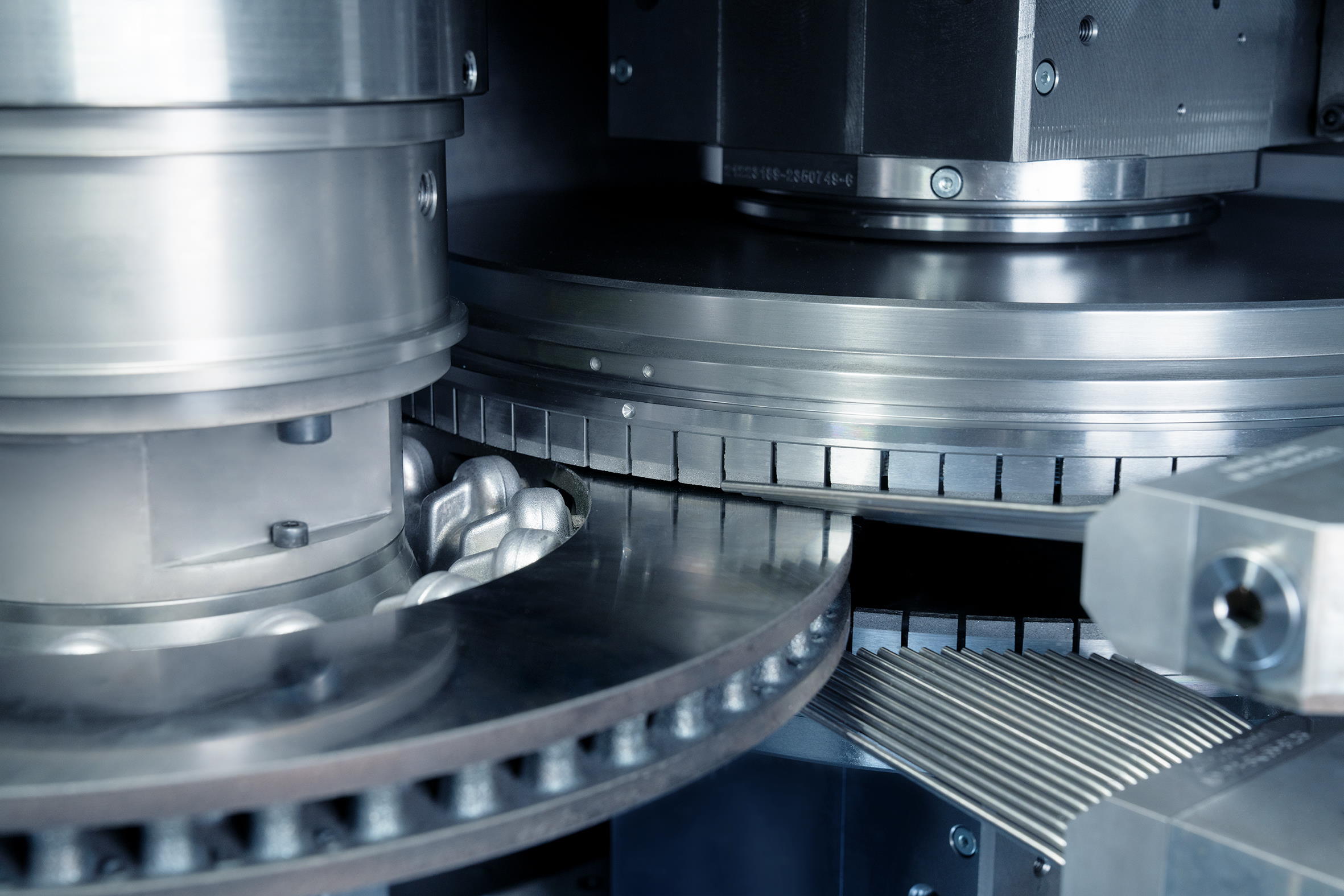

The new VST 50 from EMAG: A new ball pin leaves the machine every seven secondsWhether in the steering system or in the chassis - ball joints are indispensable in our cars. They not only act as a kind of pivot point between different elements, but are also usually in constant motion and exposed to high physical loads. In this context, ball pins and ball sleeves are among the…

07/09/2024 - Oliver Hagenlocher - 客户案例

MR Components relies on intelligent automation with EMAG machines and benefits from unmanned production in the evening hoursMR Components, a medium-sized company from Grigno, Italy, has significantly increased its production capacity and simultaneously improved quality by introducing intelligent automation with EMAG machines. The company, which specializes in the production of parts for differential and planetary gears,…

05/03/2024 - Oliver Hagenlocher - 新闻中心

New opening of the EMAG plant in Querétaro, MexicoThe EMAG Group opened its new plant in the San Isidro Business Park in Querétaro, Mexico, on April 25, 2024. This step is another milestone in the company's 20-year success story in the Mexican market and underscores EMAG's commitment to the region.

04/25/2024 - Oliver Hagenlocher - 新闻中心

EMAG at the GrindingHub 2024 – Grinding technology for the low-emission mobility of the futureGrinding is a key technology for the resource-saving and low-emission mobility of the future. Examples of this include electric drives, which place the highest demands on the precision and surface properties of transmissions and engine components, or brake discs with reduced fine dust and hard…

04/10/2024 - Oliver Hagenlocher - 新闻中心

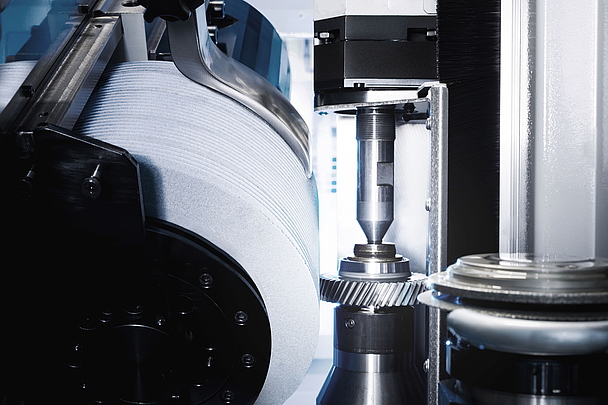

埃马克金坛公司的数控机床 WPG 7:确保在最小的空间内实现快速外圆磨削工艺在许多应用领域中,使用超大型万能外圆磨床对较小的工件进行外圆磨削是不经济的--不仅浪费了大量的占地面积,而且不能充分利用机床的功能。埃马克金坛公司目前正在通过新型 WPG 7 数控外圆磨床向世人展示另一种磨削最大长度为 250 毫米工件的方法。这台非常小的机床只需要很小的占地面积,但同时配备了一系列高科技组件,以提高灵活性和生产率。什么是最重要的细节?

03/13/2024 - Oliver Hagenlocher - 新闻中心

EMAG is working on "green manufacturing": Pulling out all the stops for greater energy efficiencyHow important is the topic of "climate-neutral production" for industry at this moment? A recent survey conducted by the German Engineering Federation (VDMA) among its member companies provided an impressive answer. According to the survey, more than three quarters of companies have set their own…

02/27/2024 - Oliver Hagenlocher - 客户案例

巴拉特锻造公司依靠埃马克公司:全面完善定子外壳的加工工艺Bharat Forge Daun的专家们正在解决的机械加工挑战包括,为高科技应用提供异常复杂的部件和高强度材料,如用于电动汽车的定子外壳,其质量需要保证在微米范围内。就在这一切的中心:埃马克的多台立式车床每周五天全天候工作。对于这样的生产需求,埃马克的服务显然尤为重要。但是,决定投资这些机床的决定性因素究竟是什么呢?

02/02/2024 - Oliver Hagenlocher - 新闻中心

EMAG Middle East Announces Opening of Office with International Free Zone in DubaiThe EMAG Group has officially opened its new sales company EMAG Middle East with the International Free Zone Authority (IFZA) in Dubai. With this expansion, the company is taking an important step into the fast-growing markets of Central Asia and the Middle East.

01/09/2024 - Oliver Hagenlocher - 新闻中心

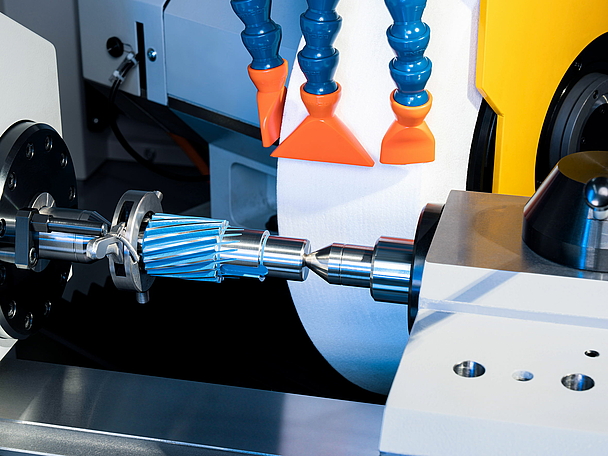

埃马克SU的磨削解决方案:为电动汽车提供极佳的表面质量几十年来,高精度和工艺可靠性一直是汽车工程的特点。然而,随着电动汽车的发展,这些要求再次提高,„“因为许多电动马达组件需要更加“完美”地制造。在大多数情况下,这涉及到微米范围内的最高表面光洁度,从而使齿轮部件不会产生巨大的运转噪音。例如,因为电动马达是静音的,这些噪音会被人听到。在这种情况下,埃马克SU的技术引起了许多生产规划者的关注:另外,专家们还开发高性能的磨齿解决方案,包括短的切换时间、智能轴概念、热稳定性和机械稳定性以及高度的用户友好性。哪些机床和工艺是重点?