Presse

09/09/2024 - Oliver Hagenlocher - Presse

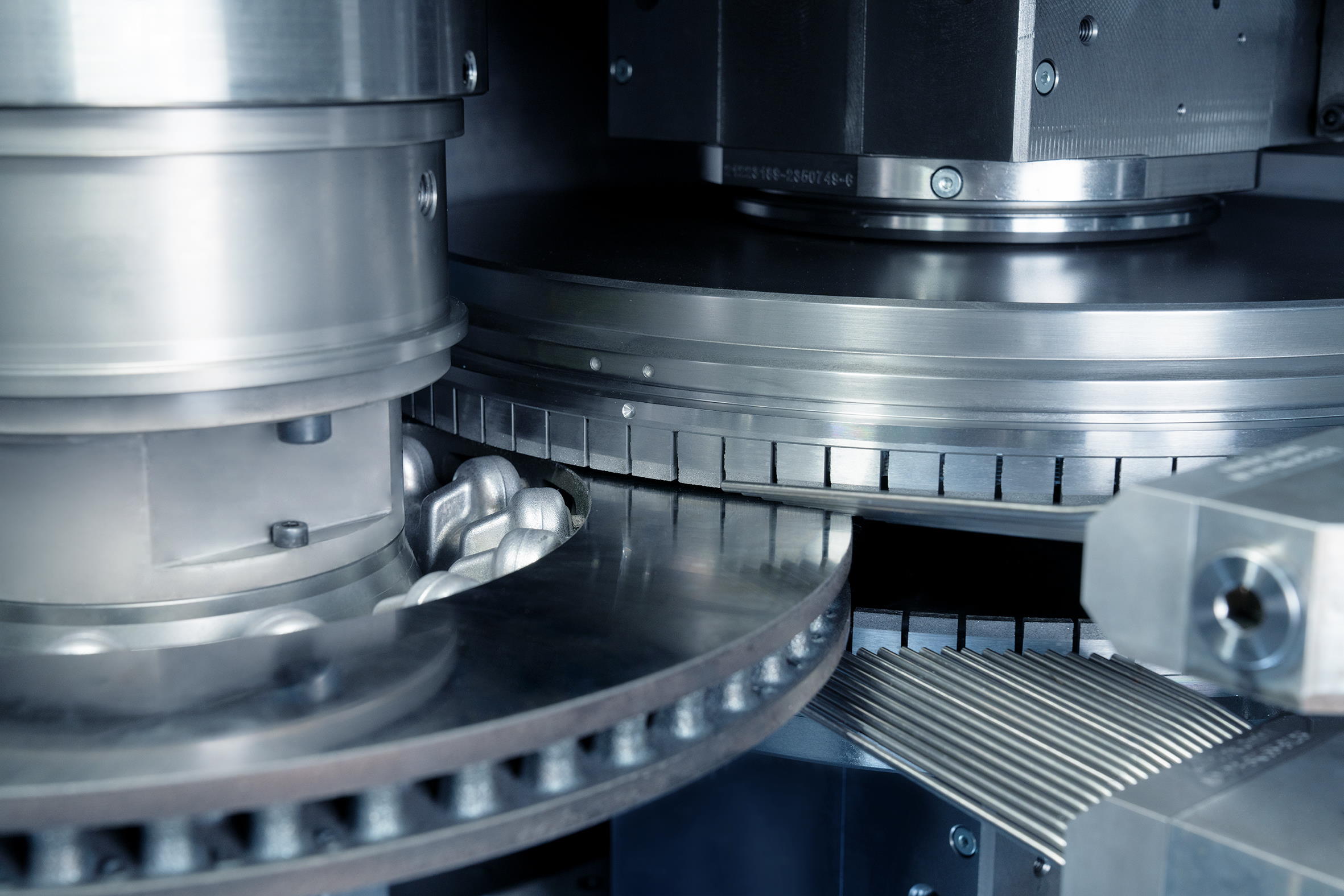

The new VST 50 from EMAG: A new ball pin leaves the machine every seven secondsWhether in the steering system or in the chassis - ball joints are indispensable in our cars. They not only act as a kind of pivot point between different elements, but are also usually in constant motion and exposed to high physical loads. In this context, ball pins and ball sleeves are among the…

09/07/2024 - Oliver Hagenlocher - Témoignages clients

MR Components relies on intelligent automation with EMAG machines and benefits from unmanned production in the evening hoursMR Components, a medium-sized company from Grigno, Italy, has significantly increased its production capacity and simultaneously improved quality by introducing intelligent automation with EMAG machines. The company, which specializes in the production of parts for differential and planetary gears,…

03/05/2024 - Oliver Hagenlocher - Presse

New opening of the EMAG plant in Querétaro, MexicoThe EMAG Group opened its new plant in the San Isidro Business Park in Querétaro, Mexico, on April 25, 2024. This step is another milestone in the company's 20-year success story in the Mexican market and underscores EMAG's commitment to the region.

25/04/2024 - Oliver Hagenlocher - Presse

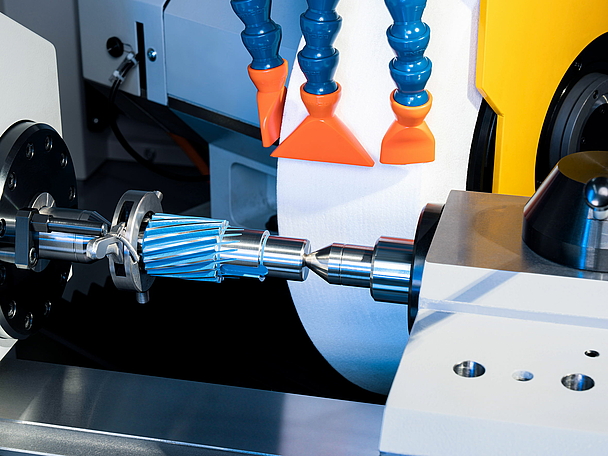

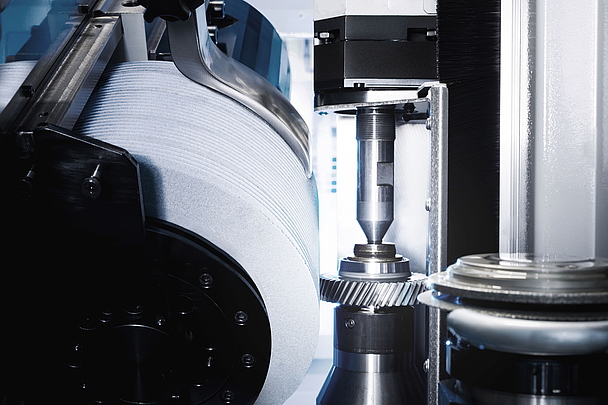

EMAG at the GrindingHub 2024 – Grinding technology for the low-emission mobility of the futureGrinding is a key technology for the resource-saving and low-emission mobility of the future. Examples of this include electric drives, which place the highest demands on the precision and surface properties of transmissions and engine components, or brake discs with reduced fine dust and hard…

10/04/2024 - Oliver Hagenlocher - Presse

WPG 7 d'EMAG Weiss : Assurer des process de rectifications extérieures rapides dans une implantation réduiteDans de nombreux domaines d'application, il n'est pas économique d'utiliser des rectifieuses cylindriques universelles surdimensionnées pour l'usinage extérieur de pièces plutôt petites - on perd ainsi beaucoup de place, sans pour autant exploiter la fonctionnalité. Avec sa nouvelle rectifieuse…

13/03/2024 - Oliver Hagenlocher - Presse

EMAG is working on "green manufacturing": Pulling out all the stops for greater energy efficiencyHow important is the topic of "climate-neutral production" for industry at this moment? A recent survey conducted by the German Engineering Federation (VDMA) among its member companies provided an impressive answer. According to the survey, more than three quarters of companies have set their own…

27/02/2024 - Oliver Hagenlocher - Témoignages clients

Bharat Forge Daun mise sur EMAG : Perfectionner le processus d'usinage du boîtier de stator à tous les niveauxDes composants inhabituellement exigeants, des matériaux hautement résistants pour des champs d'application high-tech - chez Bharat Forge Daun, on fabrique par exemple des boîtiers de stator pour l'électromobilité, les spécialistes veillant toujours à la qualité dans le domaine du micron. Au milieu…

02/02/2024 - Oliver Hagenlocher - Presse

EMAG Middle East Announces Opening of Office with International Free Zone in DubaiThe EMAG Group has officially opened its new sales company EMAG Middle East with the International Free Zone Authority (IFZA) in Dubai. With this expansion, the company is taking an important step into the fast-growing markets of Central Asia and the Middle East.

09/01/2024 - Oliver Hagenlocher - Presse

Solutions de rectification d'EMAG SU : Une qualité de surface extrême pour l'e-mobilitéUne précision et une sécurité particulières des processus caractérisent la construction automobile depuis de nombreuses décennies. Avec l'avènement de l'e-mobilité, ces exigences augmentent encore, car de nombreux composants de moteurs électriques doivent être fabriqués de manière encore plus…