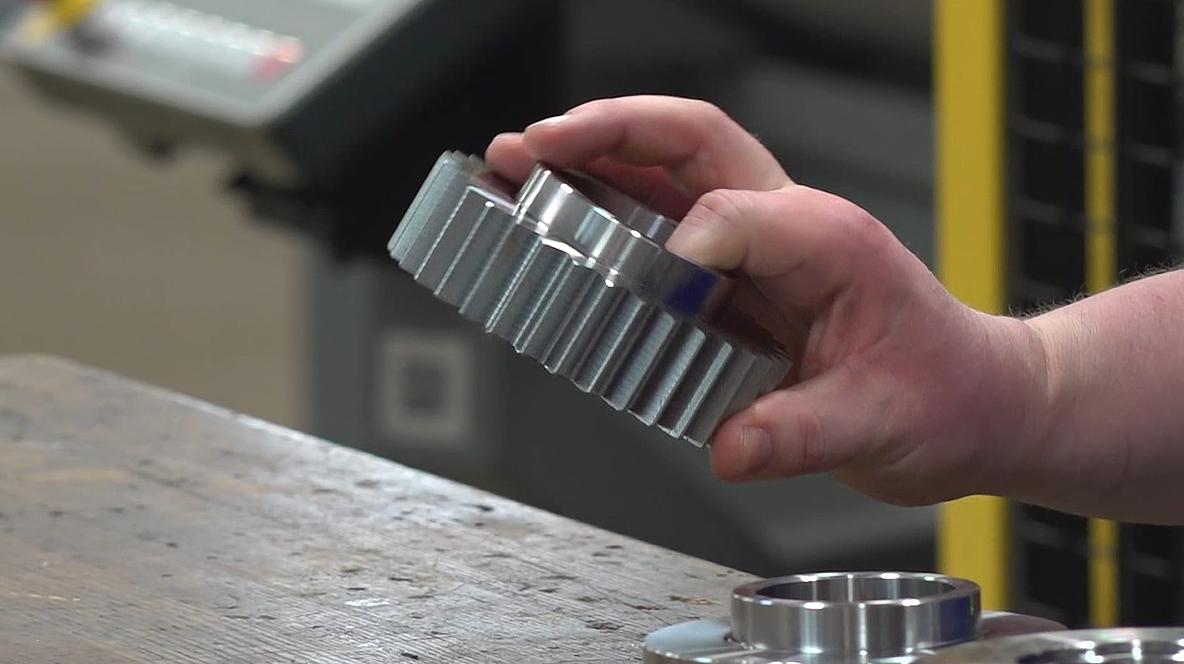

Engrenage

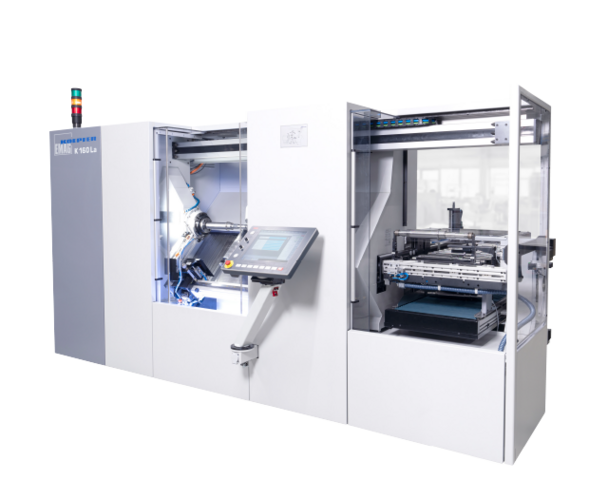

The machining process for gears utilizes machines of the VL platform, with four key operations carried out sequentially. Turning the first side and second side of the gear (OP 10 and OP 20) is done on VL 2 machines. A VLC 200 H then carries out the gear cutting process (OP 30) using a milling hob, with the concluding chamfering operation (OP 40) carried out on a VLC 100 C. The use of two different control systems (Fanuc on the VL and Siemens on the VLC) in one manufacturing system exemplifies the possibilities offered by combing different machines.

Gear manufacturing: short machining times – exceptional output rates

Demands on the manufacture of transmission components continues to increase. Modern gearboxes are becoming smaller while the number of speed-gears increases, leading to a general increase in the quantity of all gears and toothed components required. It follows that these components must be produced at the highest precision and that calls for an ever increasing number of processes. Ideally, all of these processes should also be highly flexible, with a large variety of transmission components – such as shafts, gears, planetary gears and plate carriers – frequently being manufactured at the same site.

The technologies which successfully fulfil these demands have been developed by the gearing specialists from EMAG. With innovative machine designs they have expedited developments in the production of transmission systems.

Avantages Pièce

- Compact, space-saving design

- Tailor-made automation solutions for every application

- Efficient workpiece flow, with short travels and short idle times

- Modular manufacturing concept that can be expanded and adapted at anytime

- Simple to operate manufacturing system that offers short resetting and maintenance times

- Integrated development and construction from a single source – from machine to process and automation

Technologies

Des systèmes de fabrication complexes provenant d'une seule source grâce à un large éventail de technologies

Deburring is an essential procedure in many production processes - after all, burrs that are not removed could break off later and damage bearings or…

For those who want to produce gearing on workpieces with interfering contours – including a small overrun – gear shaping is frequently the only…

Gear shaving takes place before the hardening process and is a cost-effective process. It results in low-noise gear surfaces - a major benefit that…

Machines pour vos demandes

(3) machines trouvées

Lignes de fabrication

![[Translate to French (4):] [Translate to French (4):]](https://cdn.emag.com/fileadmin/_processed_/9/d/csm_vl-3-duo_preview_69a54b85fd.png)

![[Translate to French (4):] [Translate to French (4):]](https://cdn.emag.com/fileadmin/_processed_/0/4/csm_k-300_preview_9d415d7feb.png)

![[Translate to French (4):] [Translate to French (4):]](https://cdn.emag.com/fileadmin/user_upload/content/automation_systems/trackmotion/trackmotion_preview.png)