Centres d'usinage & Fraiseuses

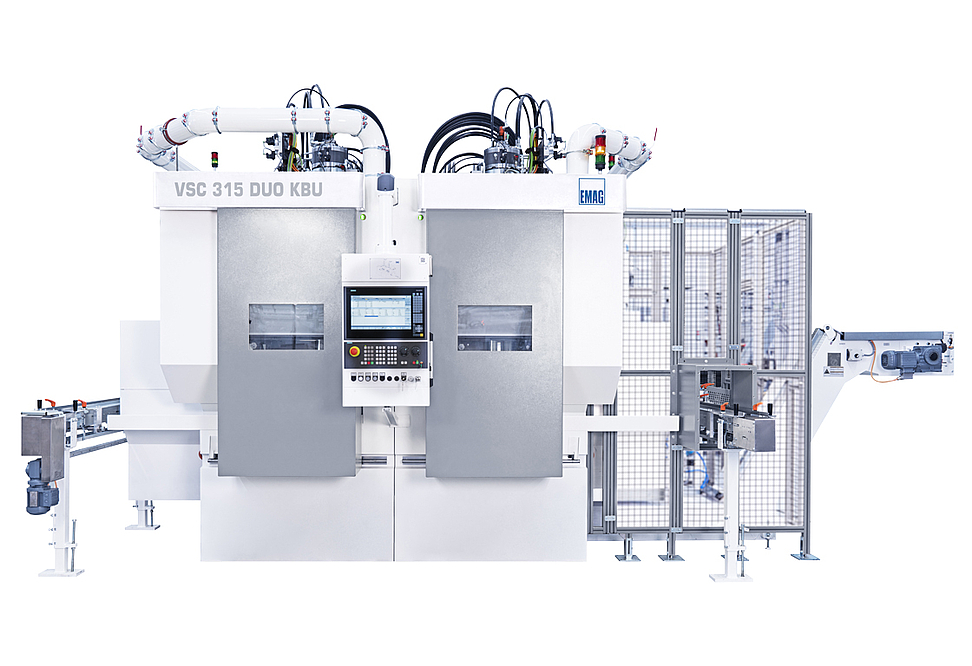

VSC 315 DUO KBU

- Longueur maxi. de la pièce: mm/in 280/11*

- Ø max. de la pièce: mm/in 160/6,5*

- Ball diameter max.: 30 mm | 1 in

Double-spindle vertical spherical milling and turning center - VSC 315 DUO KBU

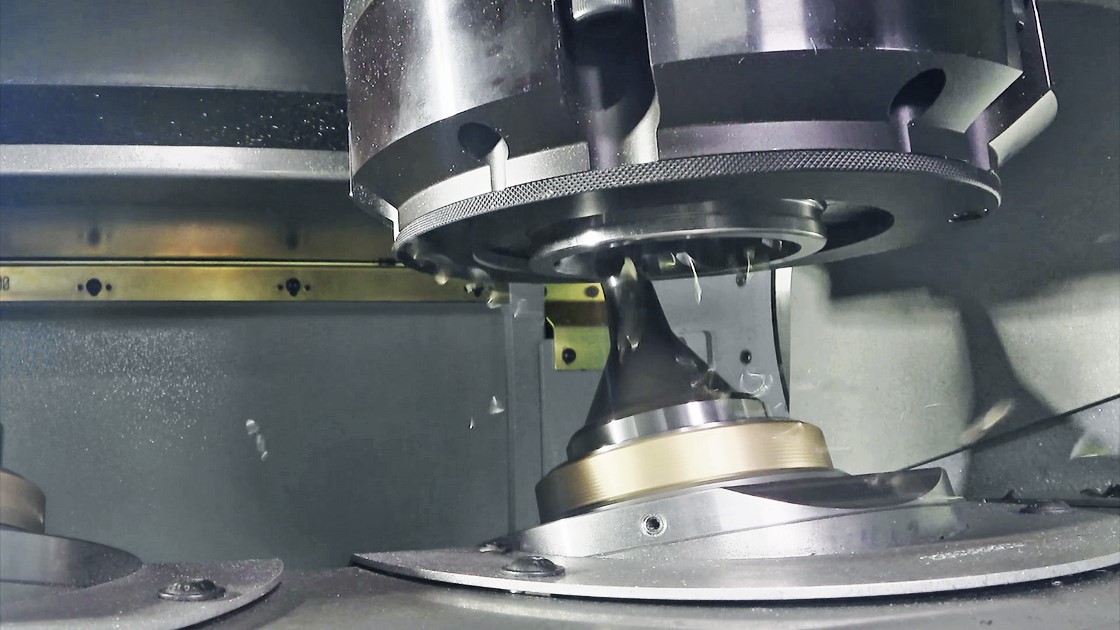

The VSC 315 DUO KBU sets new standards in efficiency and precision. Specially developed for the high-productivity manufacturing of ball raceways in joint housings (axle journals, joint rings) and ball hubs (joint hubs), it combines the technologies of soft turning, soft milling, hard turning and hard milling and enables the machining of the workpieces in one setup.

Double-spindle complete-machining in a single setup

The heart of the VSC 315 DUO KBU is the twin spindle arrangement. It enables a significant increase in productivity with consistently high quality.

The design of the machine impresses with a double-walled construction, also called gantry design, which in combination with a base body made of polymer concrete ensures maximum stability. This solid base enables both soft and hard machining at the highest level. A special feature is the integration of hard turning and hard milling in one machine. This eliminates possible clamping errors and ensures a consistently high quality of the end product.

Another outstanding feature is fully automated production, which allows the machine to be easily integrated into manufacturing systems.

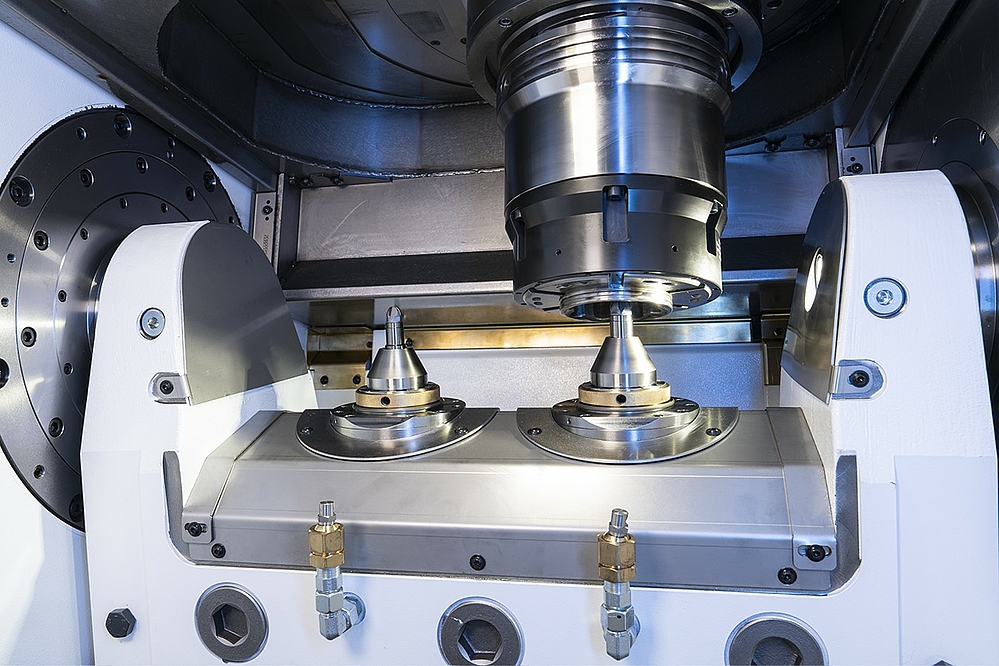

Technically, the VSC 315 DUO KBU impresses with two milling heads with milling spindles mounted on an NC swivel unit (B axis). The swivel angle of -30° to +90° and the drive via a torque motor enable flexible and precision simultaneous machining of two workpieces. The two spindle units with maintenance-free AC synchronous spindle motors stand for performance and durability. The triple bearing and thermo-symmetrical construction guarantee constant accuracy and thus reliable product quality.

Pièces

The Right Manufacturing Solution for Every Workpiece

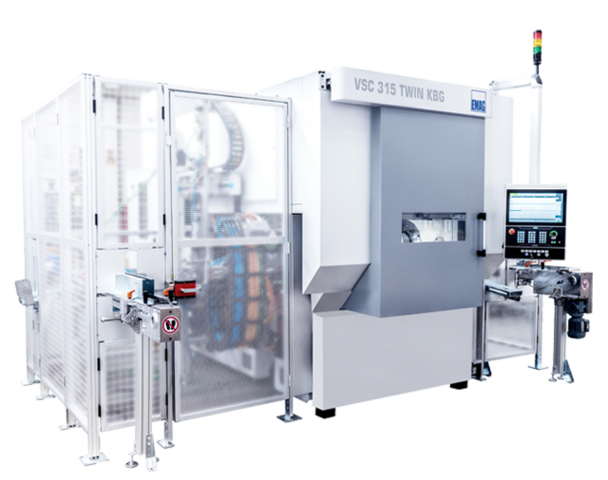

Machines pour vos demandes

(2) machines trouvées

Informations techniques

Longueur maxi. de la pièce

280/11* mm/in

Ø max. de la pièce

160/6,5* mm/in

Ball diameter max.

30 mm

1 in

| Longueur maxi. de la pièce | mm/in | 280/11* |

| Ø max. de la pièce | mm/in | 160/6,5* |

| Ball diameter max. |

mm

in |

30

1 |

| Passage du mandrin max. |

mm

in |

254

10 |

| Ø de passage |

mm

in |

260

10 |