Generating Grinding: Precise Geometries and High-Precision Surfaces for Gearing

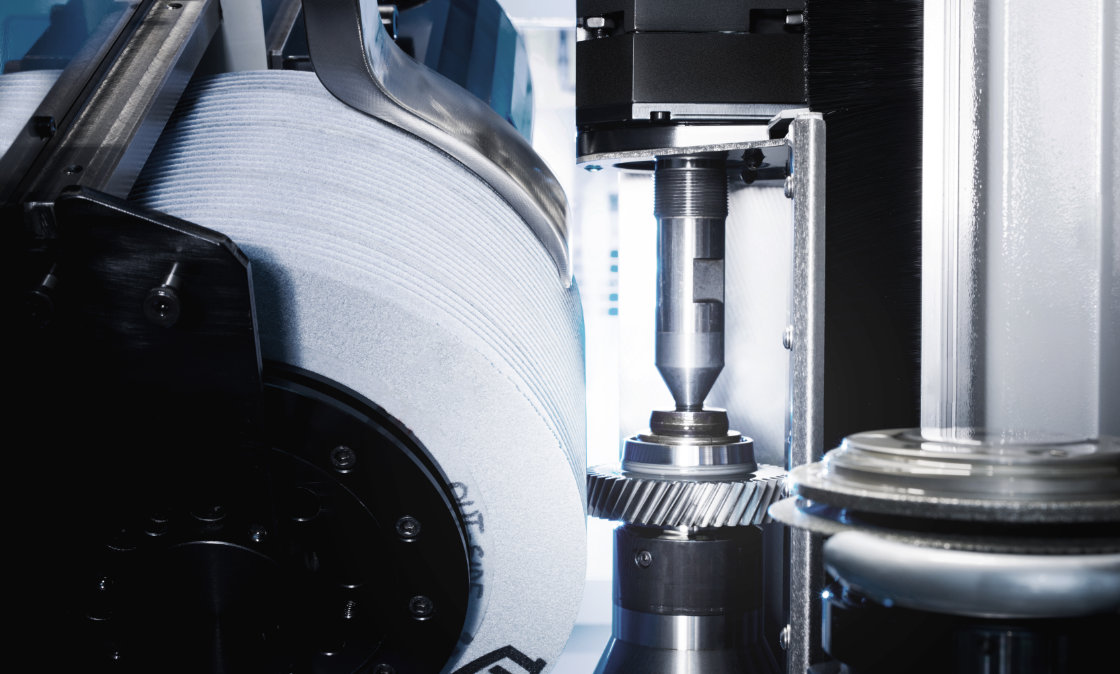

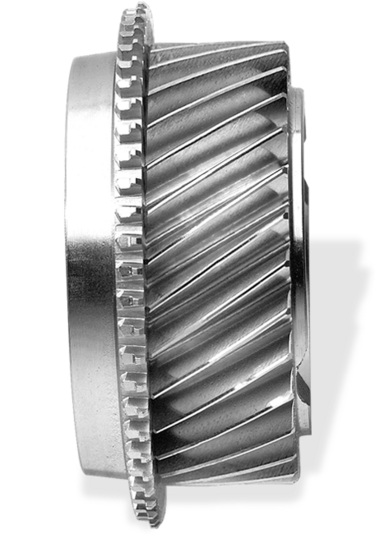

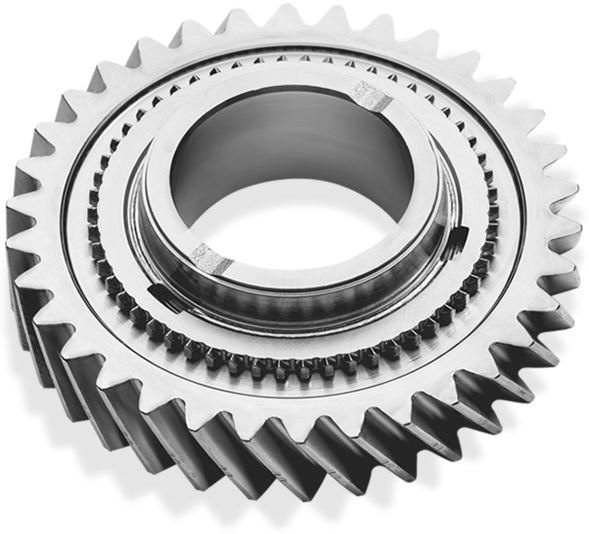

During the machining of the tooth flanks of shafts and gears by means of generating grinding or gear grinding, it is important to achieve dimensionally accurate results in the mµ range, because even minimal ripple in the surface appearance of the components can cause interference noise in the finished drive.

Rolling Movement Ensures Material Removal

Generating grinding or gear grinding are at the end of the process chain and are used after heat treatment of the component. During this process, production-related dimensional and shape deviations are eliminated. After the roughing stroke, the worm shifts tangentially and brings an unused area of the grinding wheel into position for the finishing stroke of the machining operation. This ensures that the gear geometry and the surfaces of the component meet the highest demands.

Since several flanks of the workpiece are usually in contact with the grinding worm and this has a positive effect on the metal removal rate, generating grinding is very productive. The two workpiece spindles provide an additional performance bonus: while one component is being machined, another component is being loaded onto or unloaded from the second workpiece spindle. In addition, the centering process, i.e., the introduction of the grinding wheel into the rough-cut gear component, takes place in this position in parallel with the main machining operation. On machines with only one machining spindle, the centering process is additional to the time for the main operation.

Generating grinding ensures constant shapes and flank lines along the entire circumference of the gearing. Dressing is an important factor. During this process, a diamond-coated dressing wheel is used to reset the profile of the grinding wheel to its original state, thus ensuring the required quality. All common dressing procedures are possible on the machines, including with high-speed worms.

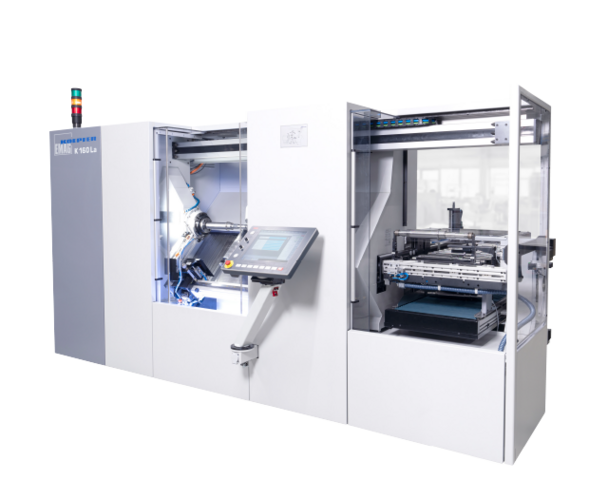

In addition to generating grinding, profile grinding wheels can also be used on EMAG SU machines. The EMAG SU G 250 HS (high speed) and G 250 are also ideally suited for workpieces with interfering contours. Grinding can be carried out with very small generating and profile grinding wheels.

Topological grinding, i.e., the compensation of surface twisting in crowned and helical gearing, can be visualized on the machine and easily modified by the machine operator. This ensures short setup times. The left and right flanks can be modified differently.

Fine or polishing grinding is carried out using a combined grinding wheel. For this purpose, the tangential axis moves into the area with the other grinding wheel condition and performs the polishing or finishing stroke.

Dry grinding, i.e., grinding without coolant, is possible on the EMAG SU SG 160, which makes the machine unique on the market. It also sets the benchmark in terms of space requirements and energy consumption (no coolant conditioning). This machine is also suitable for components that are ground before the hardening process. The (non-toothed) turning workpiece is machined on the SG160, using hobbing and generating grinding. This results in extremely short machining times and thus significantly reduces costs.

Gear grinding currently plays an important role in the production of components for e-drives, for example: Production planners are demanding new solutions for a perfect surface that ensures the required smooth running at high torques and speeds.

Avantages Generating grinding

- Fast: Highly productive machining as well as the short chip-to-chip time ensure short floor-to-floor times.

- Controlled: Short contact times reduce the risk of overheating.

- Precise: The process ensures a constant involute shape and flank lines along the entire circumference of the gearing. With special machine concepts, the fine ripple of the surface is at an extremely low level.

Pièces

The Right Manufacturing Solution for Every Workpiece

Machines pour vos demandes

(4) machines trouvées