Rectifieuses par meule mère

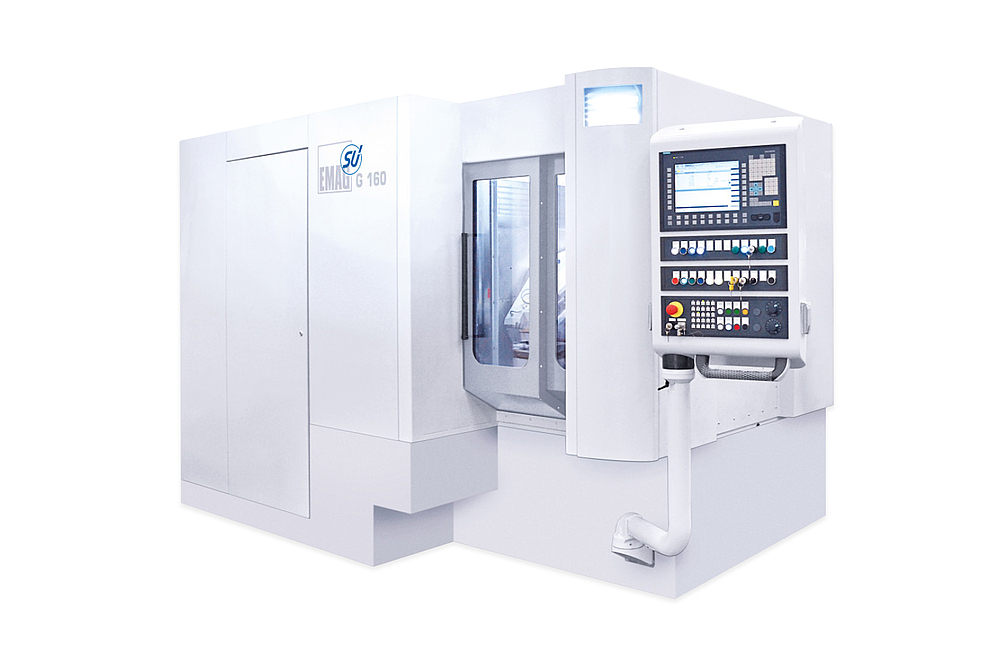

G 160

- Domaine du module: mm 0.5 - 4.0

- Ø max. de la pièce: 160 mm | 6.5 in

- Longueur maxi. de la pièce: 300 mm | 12 in

Gear Generating Grinding G 160

The G 160 gear generating grinding machine presents a unique design to optimize the dynamic stiffness compared to current standard machine architectures.

Producing Gears in the Shortest Possible Time: G 160 Gear Generating Grinding Machine from EMAG SU

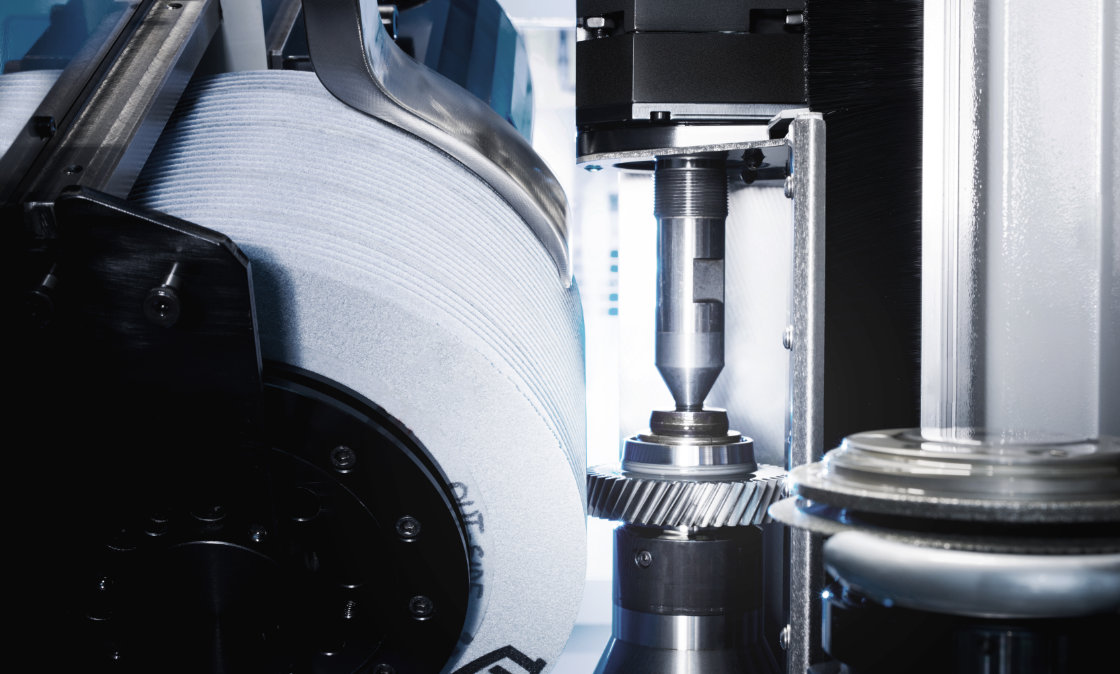

The G 160 gear generating grinding machine splits the X-axis of current machines into two linear slides (X1, X2), each of which carries one workpiece spindle.

So both work-spindles are under full position control anytime. Being driven by high dynamic 30 m/s linear motors, changing spindles comes down under 2 seconds including simultaneous repositioning of the grinding wheel. The machine architecture with only three axes instead of 4 axes concept of current machines, is a breakthrough.

The tangential axes are not in the machine and will be created by an interpolation of Z-Y-axes. This stiff machine concept ensures the best production times on the market. The increasing demand on efficiency and noise emission of the gears pushes the grinding process to its limits. The stiffness and stability of a gear generating grinding machine is the main design target for such a high dynamic process, and the G 160 presents a unique design to optimize the dynamic stiffness compared to current standard machine architectures.

Avantages G 160

- High production machine with extremely short chip to chip time

- Small footprint

- Twist control grinding

- Easy setup of the grinding wheel

- Automatic meshing of the first workpiece

Pièces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

During the machining of the tooth flanks of shafts and gears by means of generating grinding or gear grinding, it is important to achieve…

Informations techniques

Domaine du module

0.5 - 4.0 mm

Ø max. de la pièce

160 mm

6.5 in

Longueur maxi. de la pièce

300 mm

12 in

| Domaine du module | mm | 0.5 - 4.0 |

| Ø max. de la pièce |

mm

in |

160

6.5 |

| Longueur maxi. de la pièce |

mm

in |

300

12 |

| Face width, max. |

mm

in |

180

7 |

| Helix angle degree | +95° / -45° | |

| Ø de la meule | mm 275 max / 210 min |