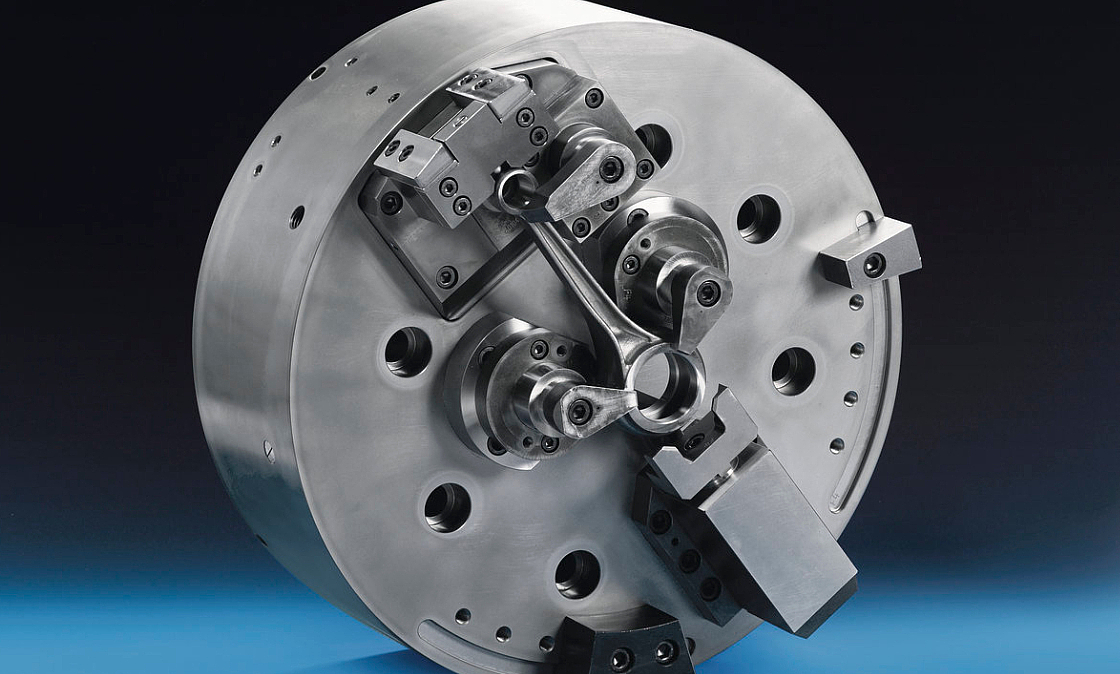

Clamping Device Maintenance

To ensure maximum productivity, clamping devices need regular maintenance. At EMAG, we will provide you with the clamping device maintenance regardless of the manufacturer.

Defective or worn clamping devices lose their precision, holding force and rigidity – which can result in decreased quality and production downtimes. With perfect clamping devices, you can make use of the full potential of production systems. With clamping maintenance, you can re-establish the like new condition of your clamping device. The performance of the clamping device is improved, which can help achieve an optimum workflow throughout the entire process chain.

Maintenance includes the removal, cleaning, inspection and repair of the clamping device. For all wearing parts and spare parts, the costs are always calculated after consultation and with proof of the individual costs. You will have full cost transparency and are guaranteed a clamping device in perfect condition.

Additionally, all necessary points are lubricated after every 20 hours in operation, in the event of severe soiling after up to every 8 hours in operation.

Complete cleaning with disassembly of the chuck is required every 2,000 - 3,000 hours in operation.

Advantages

- Reliable clamping ensures optimum machining processes

- Maximum safety for personnel and the machine

- Recovery of precision

- Higher rigidity during clamping

- Protection from premature wear of the clamping device

Technical Hotline

Our technical hotline records all inquiries and gives you technical assistance

+49 7162 17-4300

service.salach@emag.com