Modular VL

VL 4

- Workpiece dia., max.: 200 mm | 8 in

- Workpiece length, max.: 200 mm | 8 in

- Chuck dia., max.: 260 mm | 10 in

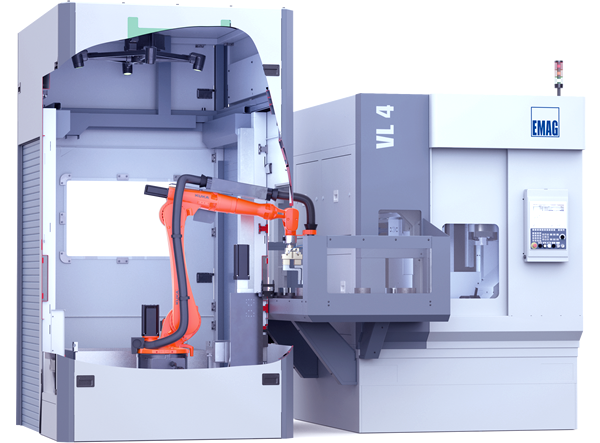

Vertical turning center VL 4 for chucked components up to 200 mm in diameter

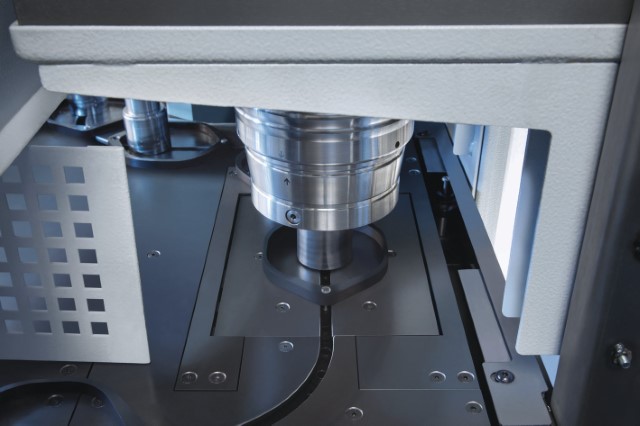

The VL 4 vertical turning center is able to machine workpieces having a maximum diameter of up to 200 mm. The VL 4 is one of EMAG's modular turning centers that stand out by their very compact design. Like all vertical turning centers in this series, the VL 4 also features an integrated pick-up automation system.

Mass production manufacturing with the VL 4 vertical turning center

The modular concept of the VL 4 makes it possible: The vertical turning center perfectly adapts to various applications, features an extremely compact design and has powerful drives. The design of the VL 4 turning center allows for the flexible implementation of various manufacturing technologies for soft and hard machining.

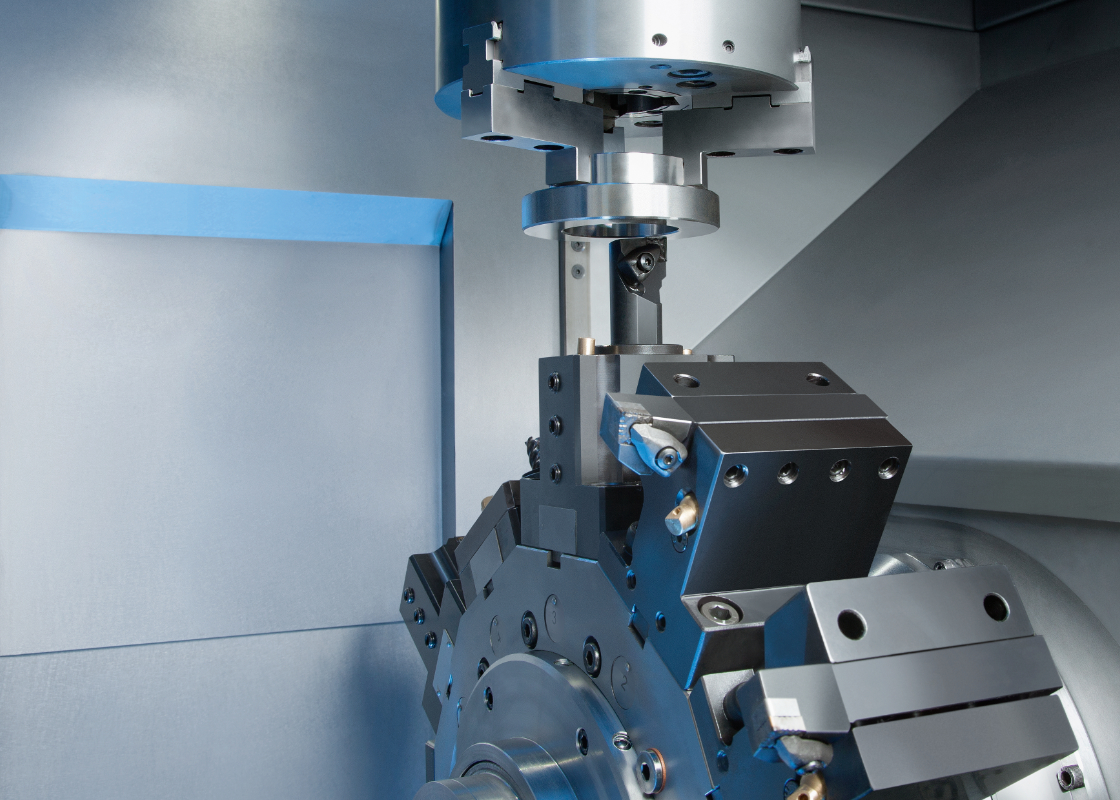

The machine base made from MINERALIT® polymer concrete allows for low-vibration machining and ensures long tool life as well as very high machining quality when turning workpieces. The main spindle is fastened to the front side by means of a compound slide rest and enables dynamic motion along the X and Z-axes. A Y-axis for complex geometries is available as an option.

A 12-post tool turret, which stands out by its very short indexing times and outstanding stability, is used for the actual machining. Excellent accessibility of the machining area and tool turret allow for the vertical turning center to be retooled in a comparably short time.

A measuring station outside the machining area is available as an option for the vertical turning centers of the VL series. The measuring station is installed between the machining area and the pick-up station. Measuring is thus performed while loading/unloading, which saves considerable time.

Vertical turning centers with integrated automation

The working spindle of the turning center loads and unloads itself from the integrated parts storage using the integrated pick-up automation system. This has two distinct advantages: On the one hand, non-productive times are reduced to an absolute minimum, as the loading position is directly alongside the machine tool’s machining area. On the other, any automation solution can be integrated to supply the vertical turning center with raw parts.

TrackMotion—modular automation solution for modular machines

The VL series turning centers can also be easily interlinked. The automation of the line is thus tailored to the customer’s preference using “modular automation systems.” The TrackMotion automation system has been specifically designed for modular vertical turning centers and makes it very easy to interlink several machines.

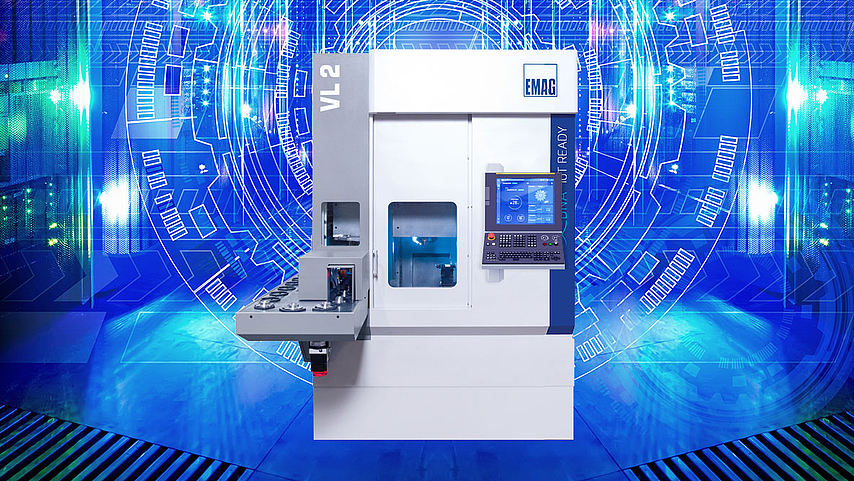

EDNA IOT-READY EX-WORKS: Get started with data-optimized production with VL series

Using data analysis, unnecessary downtimes – due to component wear or, in the worst case, due to the failure of a machine – can be reduced or even avoided entirely. Productivity increases of over 10% are the rule here. To make entering the world of data-optimized production as easy as possible for our customers, all the machines of the VL Series now come standard in an IoT-ready state. This means that data analysis on the machines can be started virtually immediately.

Advantages VL 4

- Highest productivity due to short distances

- Minimal space requirements owing to compact design of vertical turning centers

- Full automation: the machines load themselves using the pick-up spindle, the raw and finished parts storage is included

- The 12-post tool turret (also for driven tools) features very short indexing times

- All serviceable units are freely accessible and thus easy to reach

- The machine base made from MINERALIT® polymer concrete ensures high stability and outstanding vibration damping

- Vertical machining guarantees optimal chip flow

- With the addition of a Y-axis in the turret, the machine tools can be equipped to machine complex geometries

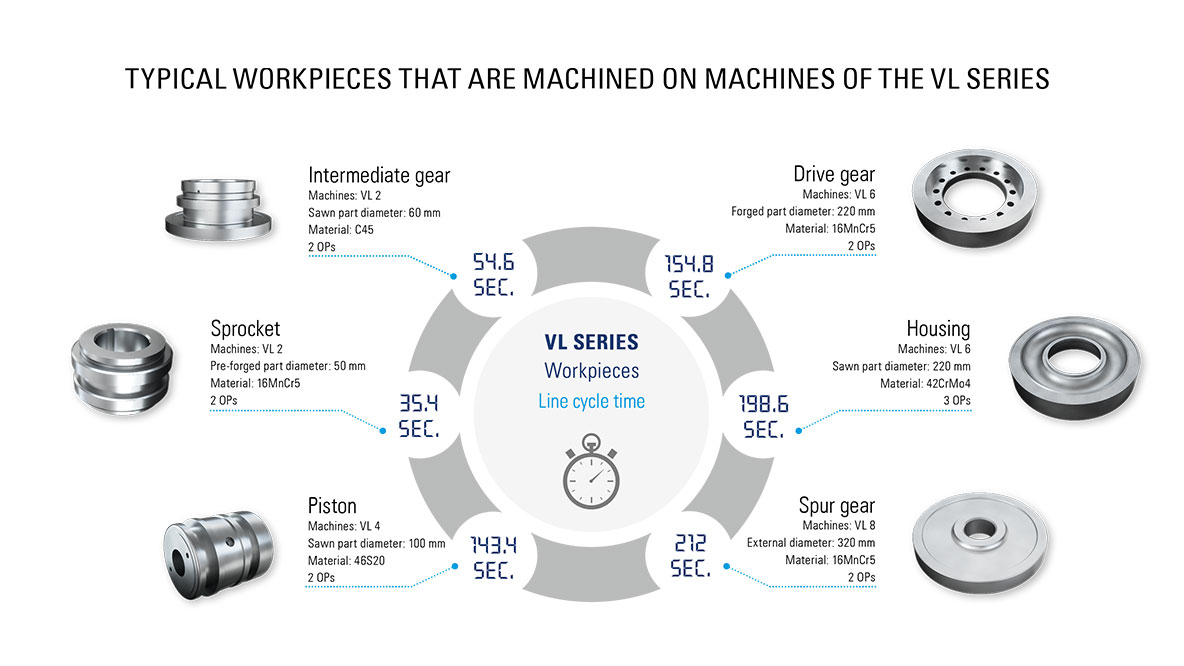

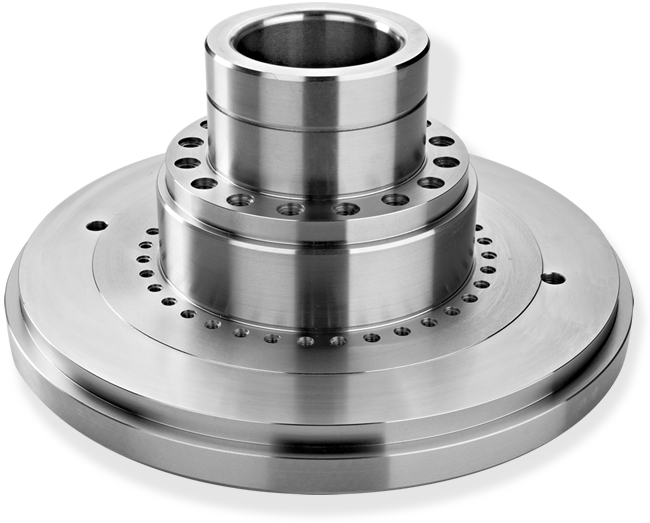

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process…

Manufacturing lines

Complete Manufacturing Lines or Automation Systems from EMAG

Digitalization

Digitalization @ EMAG - The Future is Connected

Technical Data

Workpiece dia., max.

200 mm

8 in

Workpiece length, max.

200 mm

8 in

Chuck dia., max.

260 mm

10 in

| Workpiece dia., max. |

mm

in |

200

8 |

| Workpiece length, max. |

mm

in |

200

8 |

| Chuck dia., max. |

mm

in |

260

10 |

| Swing diameter |

mm

in |

280

11 |

| X-axis travel |

mm

in |

760

30 |