Customized Shaft Machining VTC

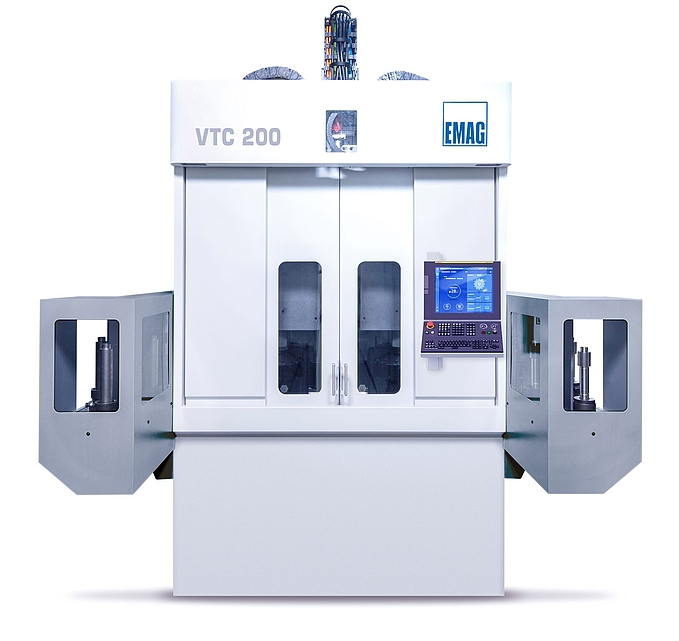

VTC 200

- Workpiece dia., max.: 200 mm | 8 in

- Workpiece length, max.: 630 mm | 25 in

- Chuck dia., max.: 250 mm | 10 in

Vertical Turning Center with Complete Freedom in Equipping for Shaft Production

The VTC 200 turning center is the customized version of the modular VT 4-4 machine. Its multifaceted configuration options make it possible to cover a wide range of applications. The vertical turning center creates diverse possibilities for users to optimize shaft production.

VTC 200 Turning Center for Flexible and Productive Shaft Manufacturing

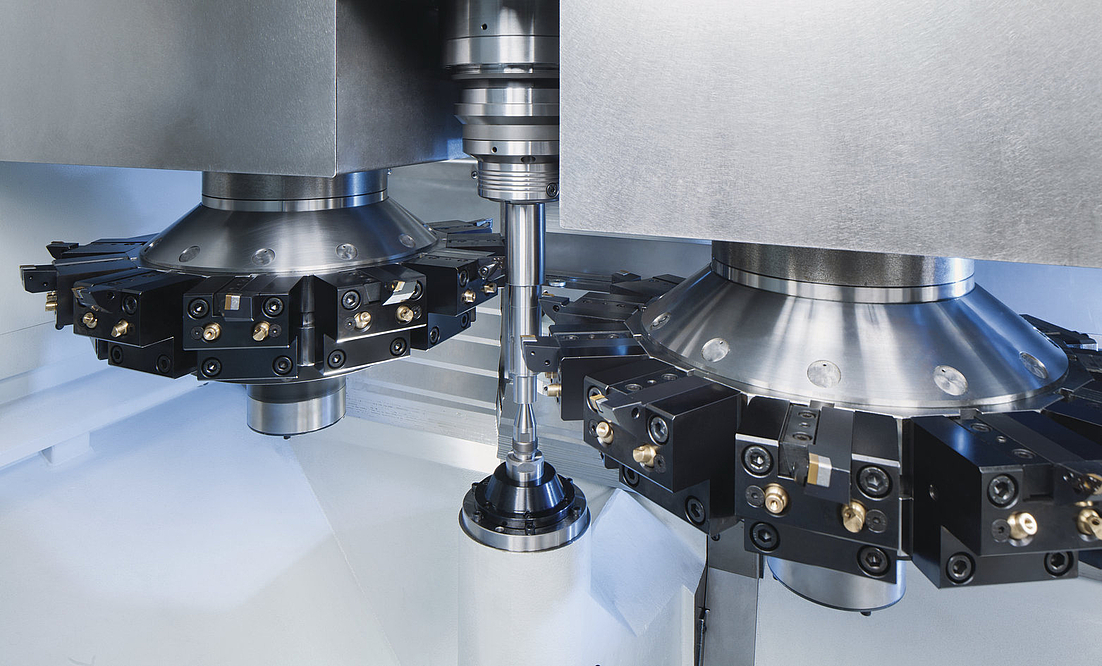

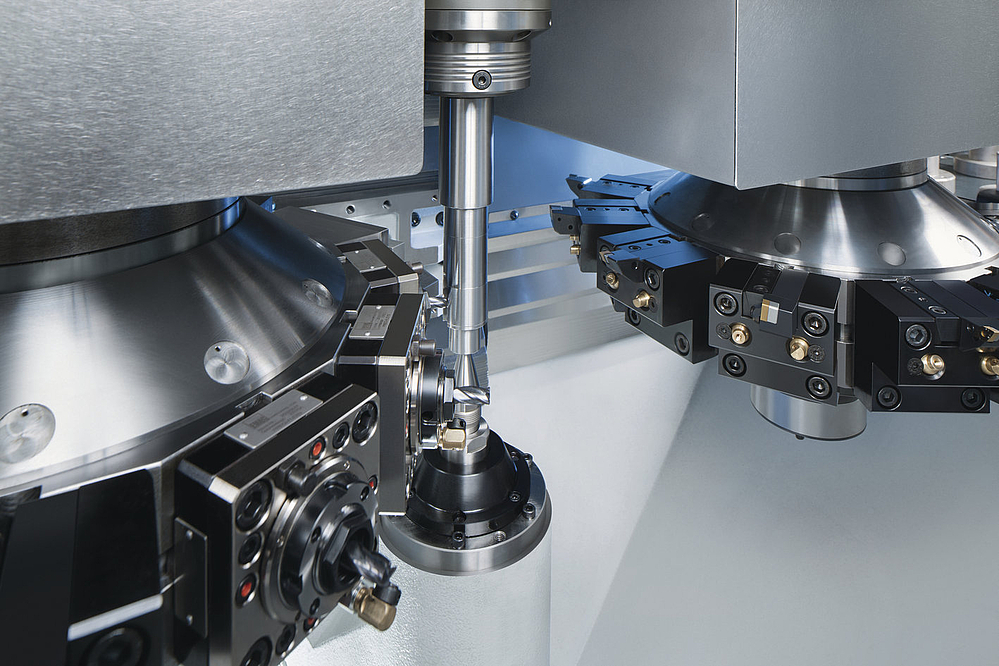

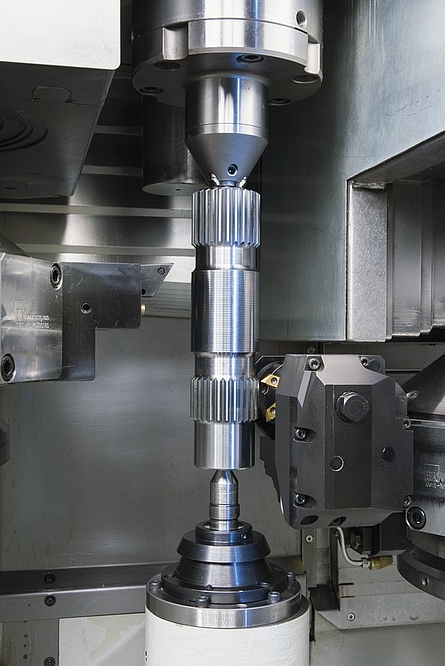

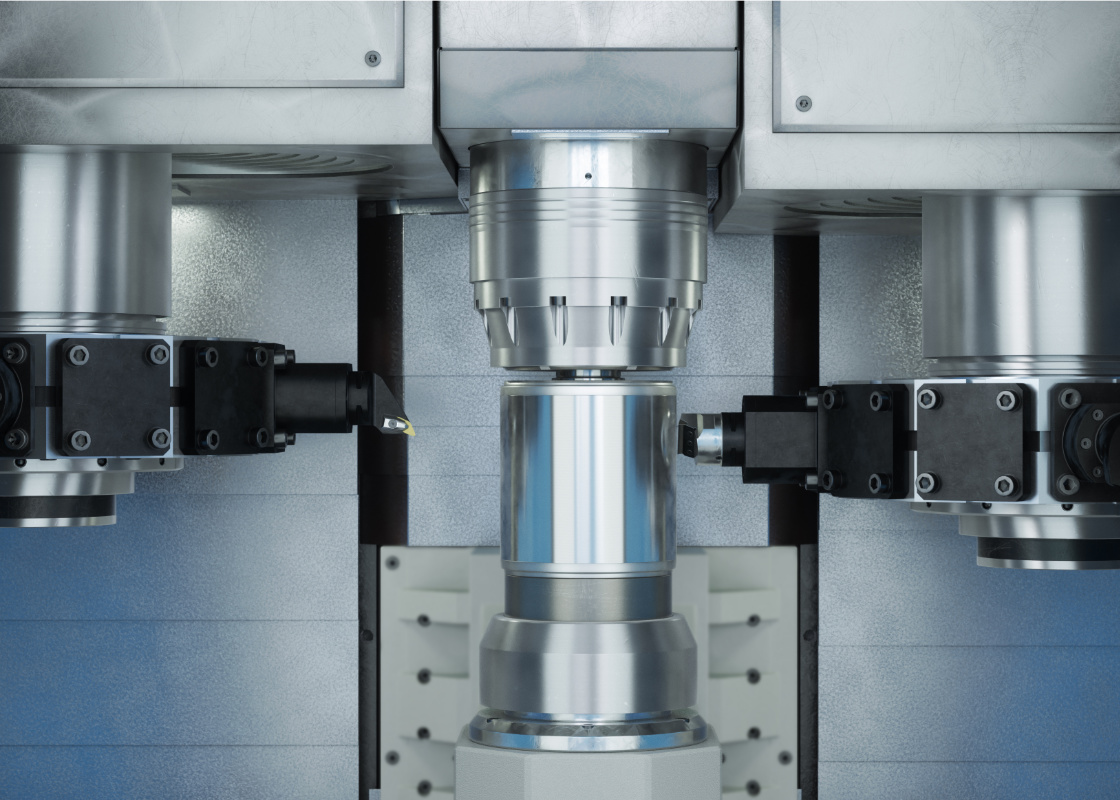

The VTC 200 vertical turning center is designed for the most productive manufacturing of shafts with a length of up to 630 mm and a diameter up to 200 mm. The turning center has two tool turrets, each with 11 tool positions for machining shafts (with the 12th position occupied by the tool gripper). This enables the four-axis machining of workpieces simultaneously from two sides, leading to a significant reduction in cycle times.

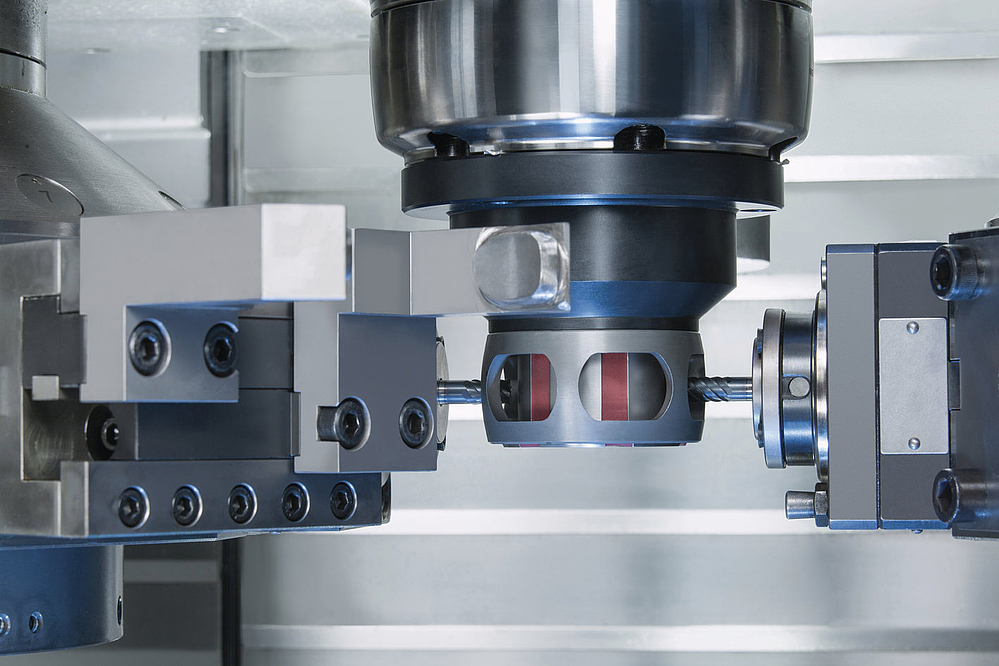

The integrated pick-up automation uses the turning center's tool grippers to optimize non-productive times. While one spindle unloads the finished part from the machining area onto the integrated conveyor belt, the other work spindle takes the next raw part from the parts storage section on the other side of the turning center and transports it to the machining position.

Advantages VTC 200

- Reduced cycle times with 4-axis machining

- Less expense for sensory equipment thanks to directly driven machine axes and modern control-system technology

- Short tooling and retooling times with exceptional accessibility and user friendliness

- Fewer manual interventions (tailstock and steadies proceed under CNC control, the operator accesses the turret directly)

- The machine's vertical setup creates an unhindered chip flow, eliminating chip clusters

- Fewer costs for automation and peripherals

- Raw and finished parts storage areas are integrated components of the machine

- Shorter idle times with time-saving parts loading and unloading

- Use as individual machine or in combination as a manufacturing system

- Lower space requirements with compact, vertical design

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Scroll-free turning technology developed by EMAG offers new possibilities for fine machining. With scroll-free turning, you are able to produce…

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process…

Technical Data

Workpiece dia., max.

200 mm

8 in

Workpiece length, max.

630 mm

25 in

Chuck dia., max.

250 mm

10 in

| Workpiece dia., max. |

mm

in |

200

8 |

| Workpiece length, max. |

mm

in |

630

25 |

| Chuck dia., max. |

mm

in |

250

10 |

| Swing diameter |

mm

in |

270

10.5 |