SCS Stacking Cell

- Workpiece size, max.: 200 / 400 mm | 8 / 15.5 in

- Max. basket/pallet size (adjustable height): mm 600 x 500

- Max. weight of basket/pallet (incl. workpieces): 20 kg | 44 lb

Automation: The New Stacking Cells of the SCS Series

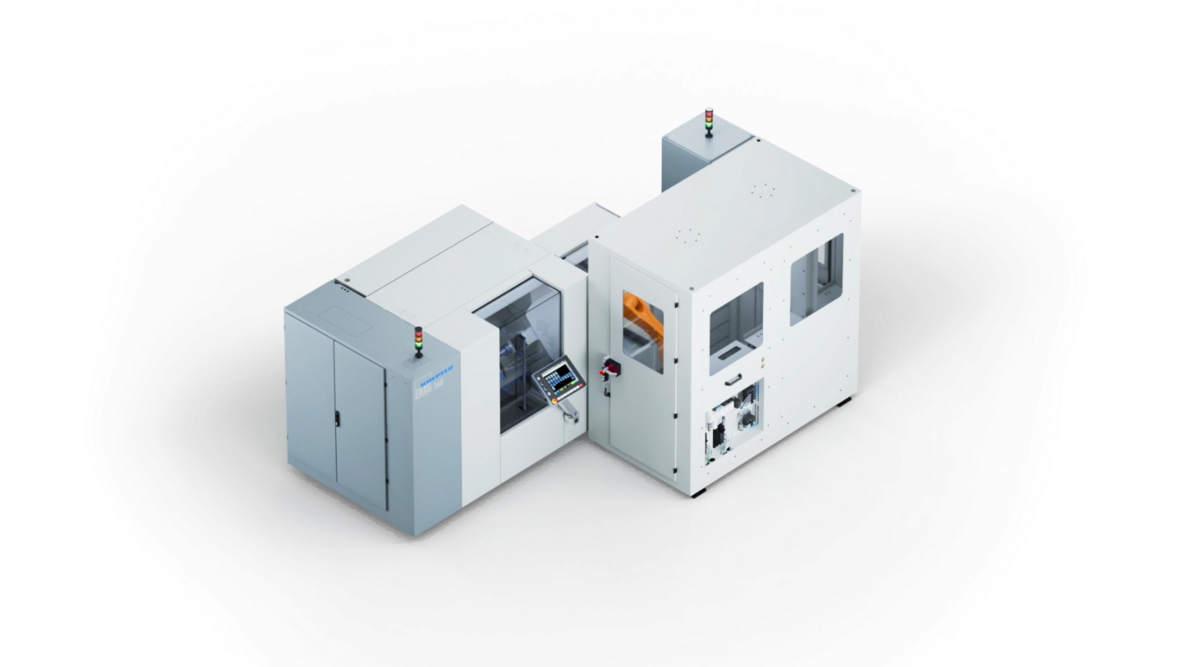

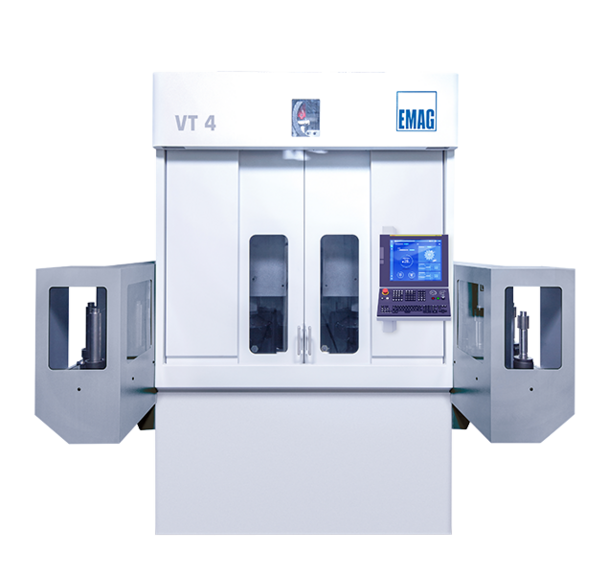

Highly productive production in a confined space – this is what is promised by the new stacking cells of the SCS series in combination with the vertical turning center from EMAG.

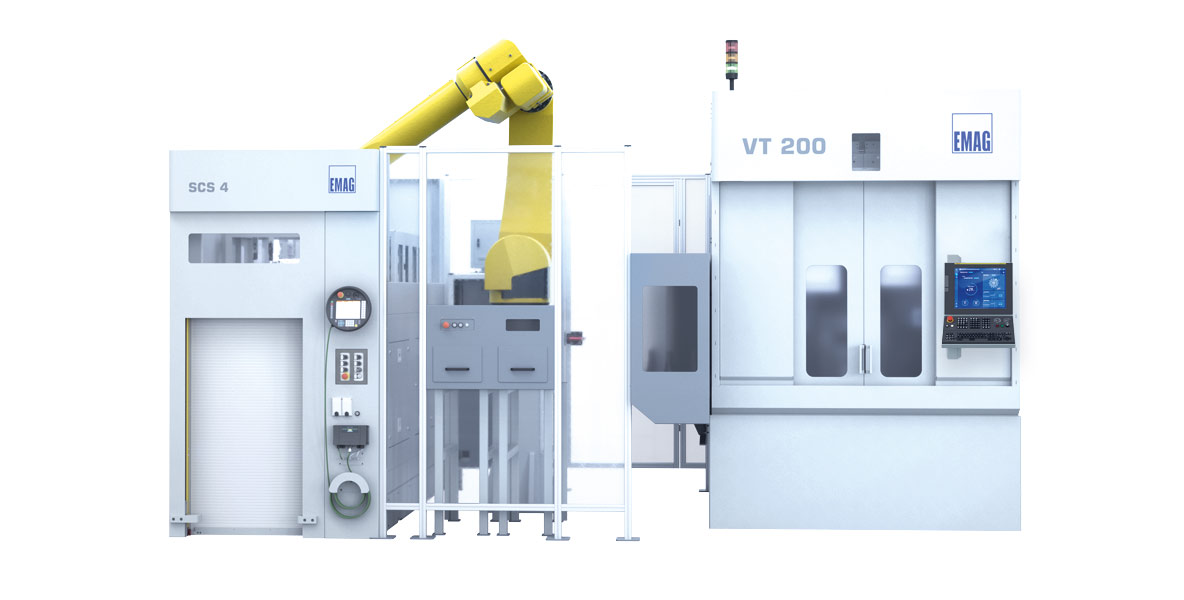

Whether for the machining of chuck parts or shaft parts, in combination with the SCS stacking cells, EMAG machines become compact, fully automated production systems that can produce autonomously for hours. Depending on the diameter of the workpieces to be machined, EMAG offers the automation system in two sizes: the SCS 1 for parts with a diameter of up to 200 mm and the SCS 4 for components with a diameter of up to 400 mm, including an automatic palletizing device with a pallet transfer unit. Parts are handled and the machines are loaded and unloaded by a robot. Of course, the integration of any well-known manufacturer is possible here.

Storage System for Highly Productive Production – The SCS Stacking Cells

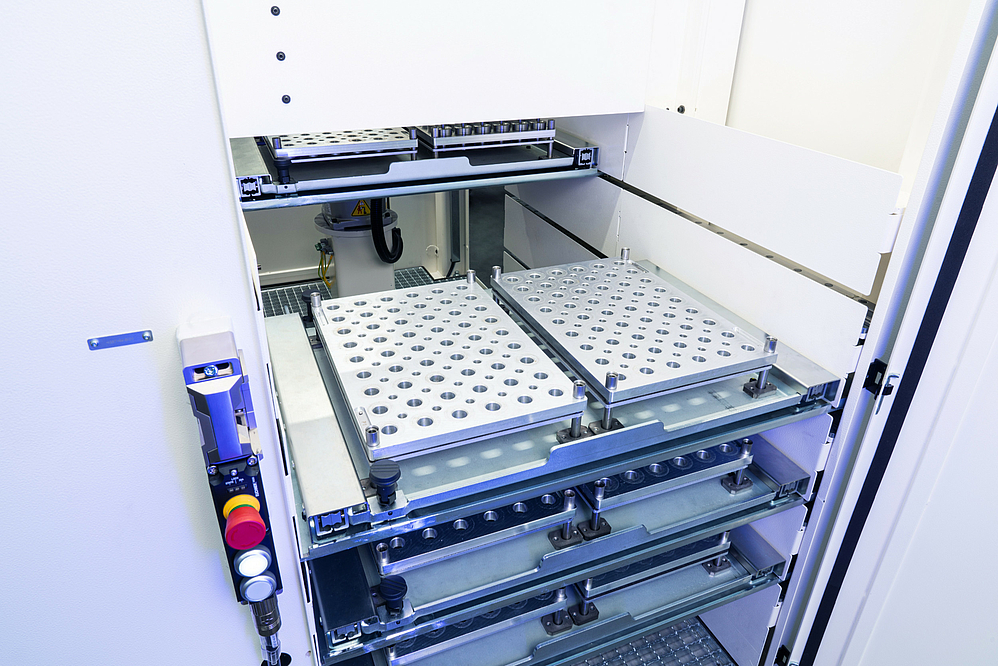

The standardized SCS storage solutions from EMAG ensure continuous material flow in your production with EMAG machines. The systems enable fast loading and unloading of the machines as if your production is never at a standstill. The SCS automation system is a storage solution with pallets or baskets that can be integrated in individual machines or production solutions. We can adapt it to existing workpiece carriers or develop completely new production sequences for the purpose of optimizing the ODE.

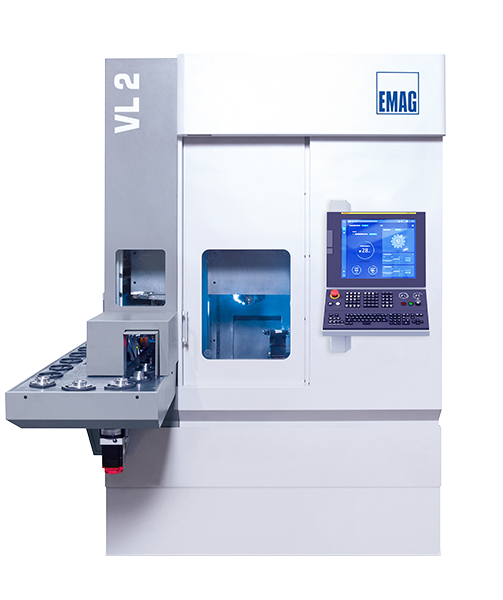

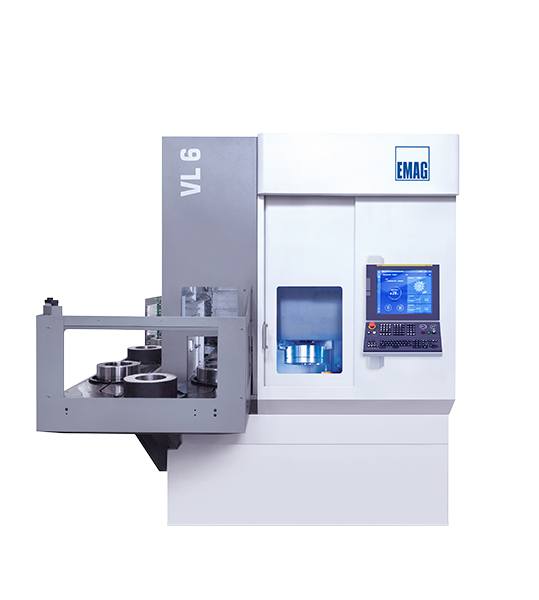

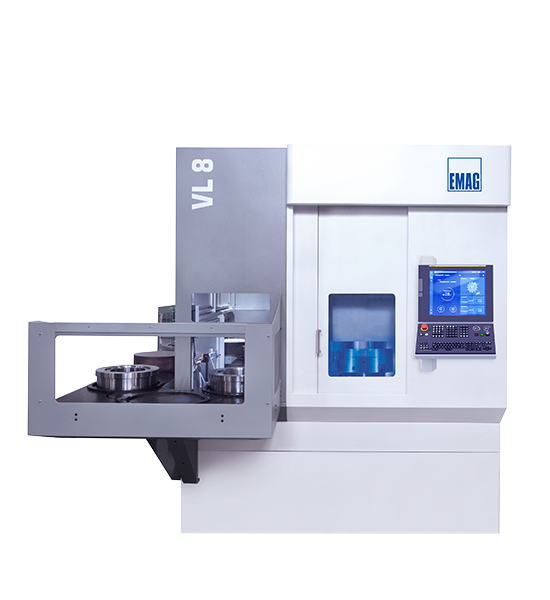

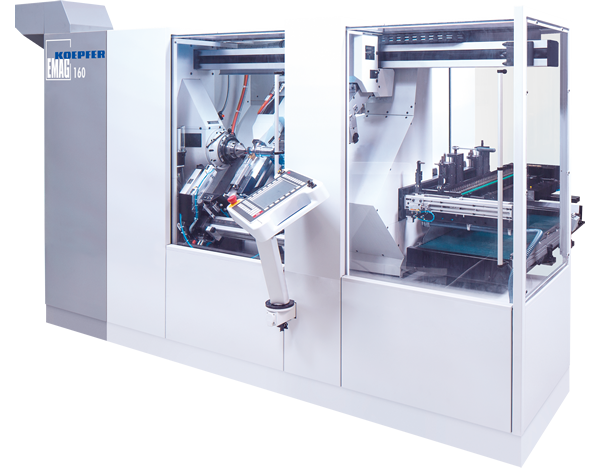

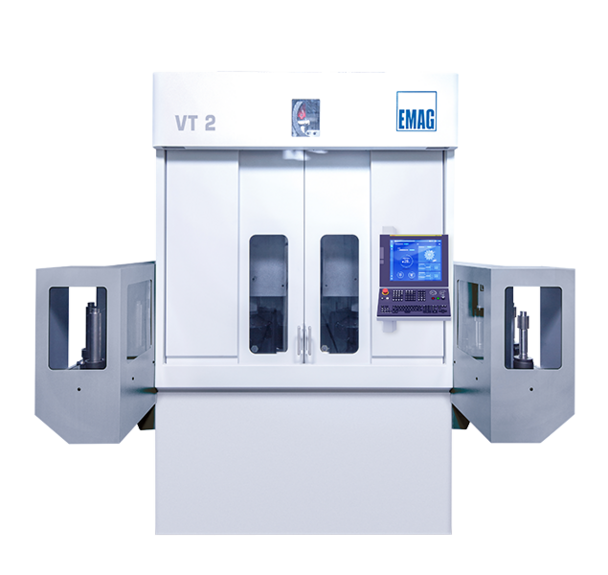

The SCS (Stacker Cell System) is a storage system for automatic loading from pallets or baskets that is available to our machines of the VL and VT series and the hobbing machines of the K series from EMAG Koepfer. Thanks to their compact design, the SCS stacking cells provide ideal design options when planning the flow of parts in production. For example, highly productive individual machine solutions can be implemented to enable an enormous increase in production at relatively low costs.

EMAG offers the SCS in different configuration stages, depending on the size of the components, and batches can also be adapted subsequently to new components. The SCS 1 is a cell with an integrated workpiece storage system and a robot for loading the workpieces into the machine. The SCS 4 is a feeding unit with integrated axis system for loading the baskets. The workpieces are loaded and unloaded from the baskets into the machine. A robot is usually used for this purpose.

We support you, of course, in the design of the pallets or baskets for your workpieces. Among other things, EMAG also offers you the option of machine or system optimization based on a permanent data analysis, provided you have the corresponding IoT systems in service.

Advantages SCS Stacking Cell

- Perfect solution for machines of the VL and VT series and hobbing machines of the K series from EMAG Koepfer

- Compact complete production solution from a single source from EMAG

- Economic production due to optimum machine utilization

- Low level of strain on the machine operator

- High storage density on small installation area

- Relatively low investment costs

- Simple retrofitting option for existing EMAG machines

Machines for your requirements

(14) machines found

Technical Data

Workpiece size, max.

200 / 400 mm

8 / 15.5 in

Max. basket/pallet size (adjustable height)

600 x 500 mm

Max. weight of basket/pallet (incl. workpieces)

20 kg

44 lb

| Workpiece size, max. | mm in | 200 / 400 8 / 15.5 |

| Max. basket/pallet size (adjustable height) | mm | 600 x 500 |

| Max. weight of basket/pallet (incl. workpieces) | kg lb | 20 44 |

We're here for you

Do you have questions or need more detailed information? Please contact us!

To contact