Scroll-Free Turning from EMAG: Fast, Precise, Reliable

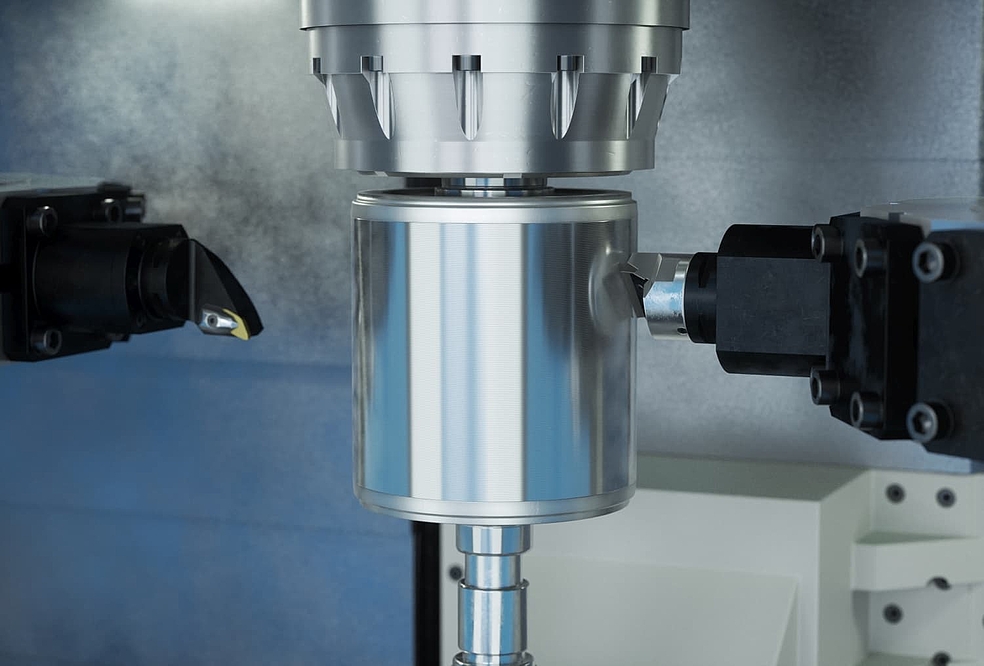

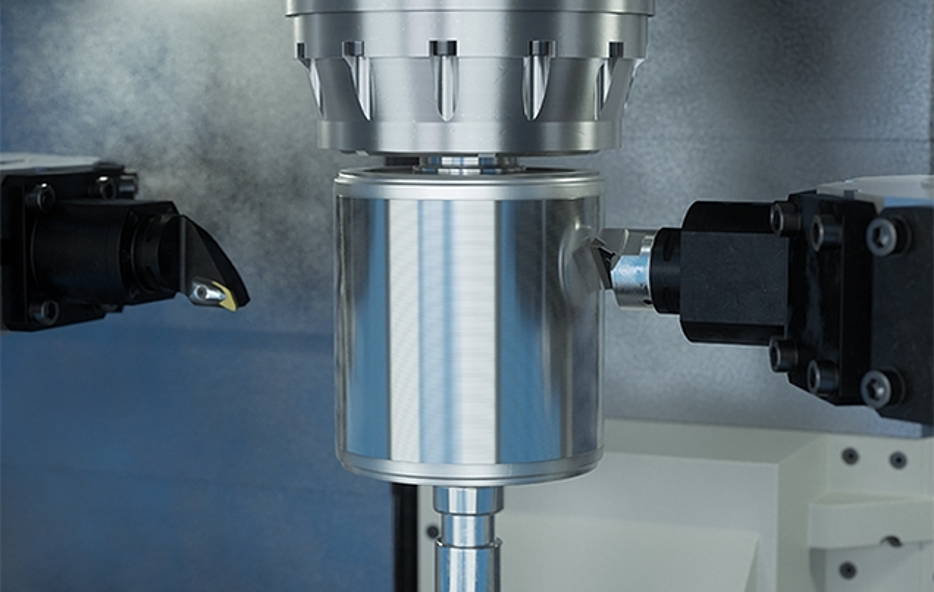

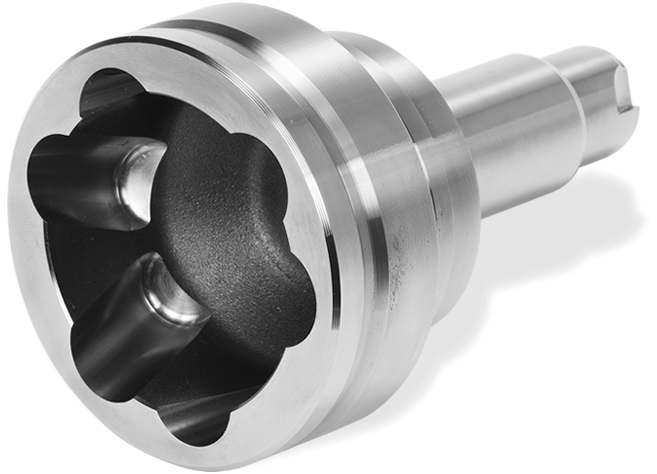

Scroll-free turning technology developed by EMAG offers new possibilities for fine machining. With scroll-free turning, you are able to produce excellent quality surfaces with very short cycle times. For example, surface qualities that could only be achieved with special grinding processes (infeed grinding) before can now be scroll-free turned (ex. seal seats) without scoring.

See the highly productive process in this video.

Scroll-Free Turning: The Quickest Machining Technology

A major advantage of scroll-free turning is its very short cycle times – this process is up to 10 times faster than grinding or longitudinal turning (corner radius 0.8 mm, feed 0.15 mm to 1.5 mm to produce a surface Rz 6.3). Completed projects have achieved surface qualities of Rz <1 µm and feed rates of up to 1 mm/rev. Even high percentage contact areas (Rmr) and modern surface requirements such as Rpk, Rvk, Rk can be met.

Longer tool life is another advantage of this technology, which is achieved by using the entire cutting edge. This results in a positive cascade effect, that has an impact on the overall manufacturing costs. In addition to lower tool change costs thanks to a longer tool life (and engagement time of the cutting edges), machine costs are also reduced due to shorter cycle times.

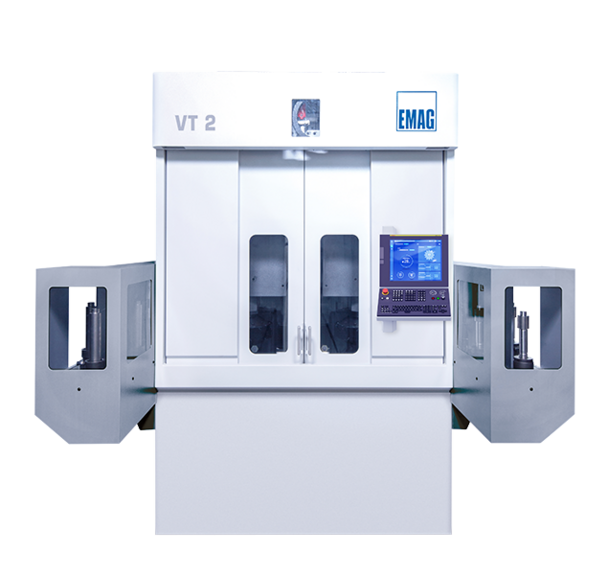

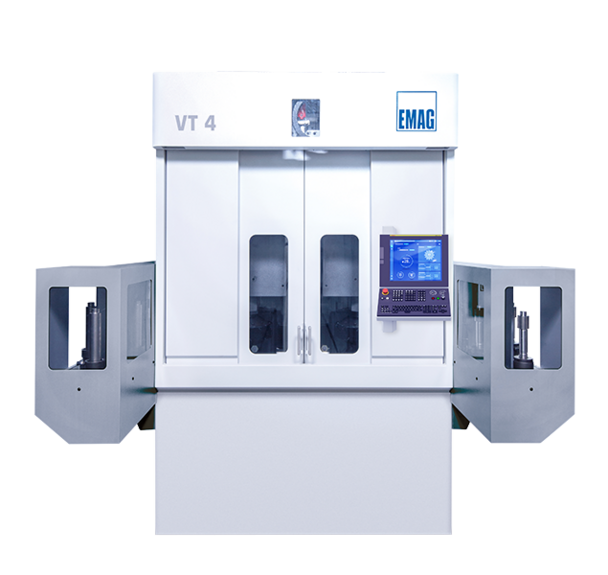

Scroll-Free Turning on EMAG's VT Series Machines

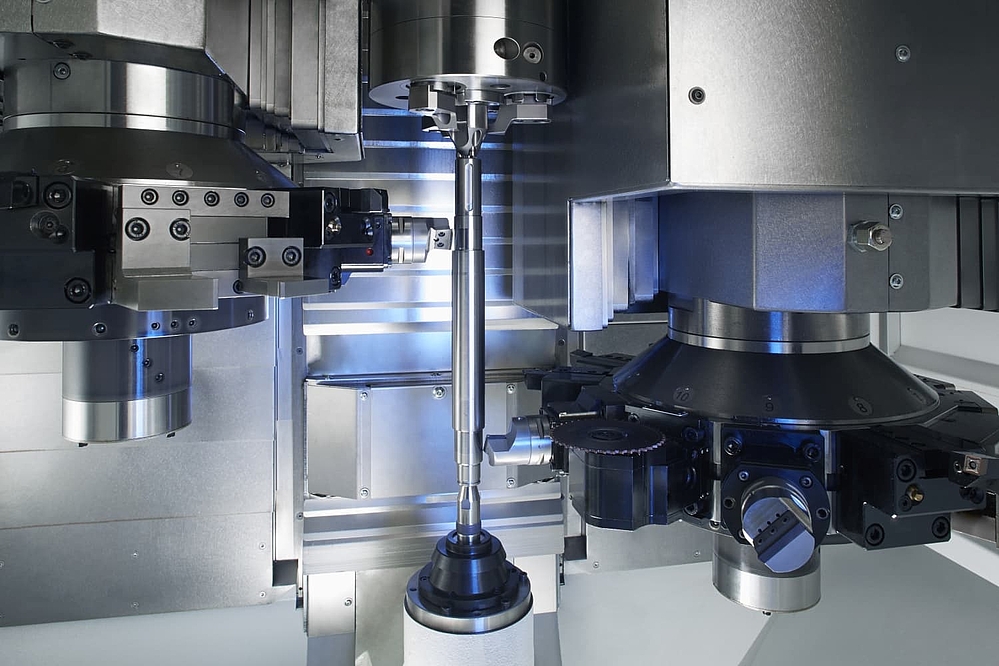

Scroll-free turning technology is already well established at EMAG and has been applied to many projects over the past 10 years for the mass production of outer races. The VT series of machines for example, were created to perfectly implement this technology. This includes both the mechanics of the machines and the turrets, as well as the parameterization of the swivel axis and its control-related adjustment. A control software system was also specifically developed for this process, and EMAG has succeeded in developing a simple mode of operation for this demanding turning process. Reach out to us today to determine if scroll-free turning can be used for your production process, such as for the soft machining of rotor shafts.

Challenges of Scroll-Free Turning

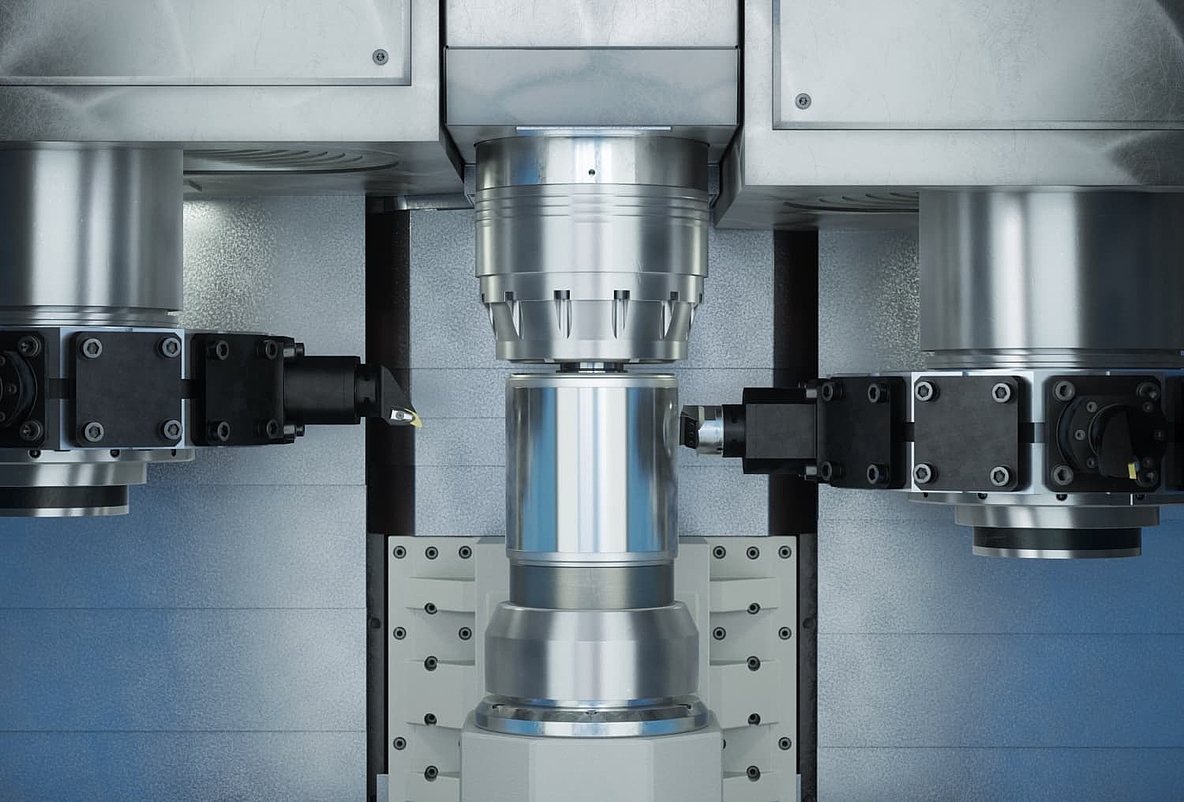

There are many advantages to using scroll-free turning when machining hardened workpieces. However, to use scroll-free turning, some conditions for both the workpiece and machine must be met.

The greatest challenge here are the machining forces present that act on the peeling plate and the workpiece. This requires a certain degree of stability for the workpiece, the clamping device, the tool holder and of course the machine itself.

With the number of variables, there is no simple answer about whether a workpiece is good for scroll-free turning technology or not. For this, our experts will use their extensive experience to provide you with the appropriate information and tips.

Our VT-series machines are designed for the addition of this technology, and are the ideal solution for machining a wide range of workpieces.

Requirements:

- Workpiece stability

- A clamping system that is perfectly matched to the workpiece

- Correct tool and process design

- Rigid tool holder and stable machine base

Advantages:

- Cost reduction by lowering tool costs and cycle times

- Elimination of additional process steps by achieving high surface qualities with Rz <1 µm

- Reduction in floor space due to fewer machine tools thanks to the very short cycle times

- Reduction in environmental impact through dry processes and low energy consumption

- Great versatility due to universal tools (machining length adapted by superpositioning of a feed) compared to grinding tools

- Hard and soft machining possible with EMAG technology

- Machines are perfectly designed for the application of scroll-free turning technology

Machining Example: For the Finish Machining of Sheet Metal Housings EMAG Relies on Innovative Scroll-Free Turning Technology

The scroll-free turning of rotor shaft sheet metal housings has a number of advantages over the traditional turning process. For one, scroll-free turning provides significantly higher feed rates per revolution, leading to a reduction in overall cycle time. Machine time is also reduced by using the entire cutting edge of the tool – providing the additional benefit of improving tool life. This technology has also proven to achieve significantly better surface qualities.

Application Example: Outer Race – Hard Machining on One Clamping Operation

Scroll-free turning replaces additional processes that were historically performed on separate grinding machines. The machining of outer races is the perfect example to demonstrate the advantages of scroll-free turning and the 4-axies VT series machines. Since outer races are manufactured in large quantities, the combination of a powerful production machine and optimum production technology can score double points here: first, the integrated automation of the machine with parallel loading and unloading ensures short non-productive times, and then the 4-axis machining accelerates the processing times. An additional speed bonus is achieved by the rapid finishing process of the bearing seat with scroll-free turning, which not only produces a perfect surface without scoring, but also eliminates the need for any finishing work.

The machining of outer races in this configuration is a real cost killer: Not only are extremely low cycle times achieved, which significantly reduces the costs per workpiece, but investment costs are also lower, as no additional grinding machine needs to be planned.

Workpieces

The Right Manufacturing Solution for Every Workpiece

Machines for your requirements

(8) machines found