Customized Shaft Machining VTC

VTC 250 / 250 DUO

- Workpiece dia., max.: 140 mm | 5.5 in

- Workpiece length, max.: 1,000 mm | 39.5 in

- Chuck dia., max.: 280 mm | 11 in

VTC Customized Vertical Shaft Machining

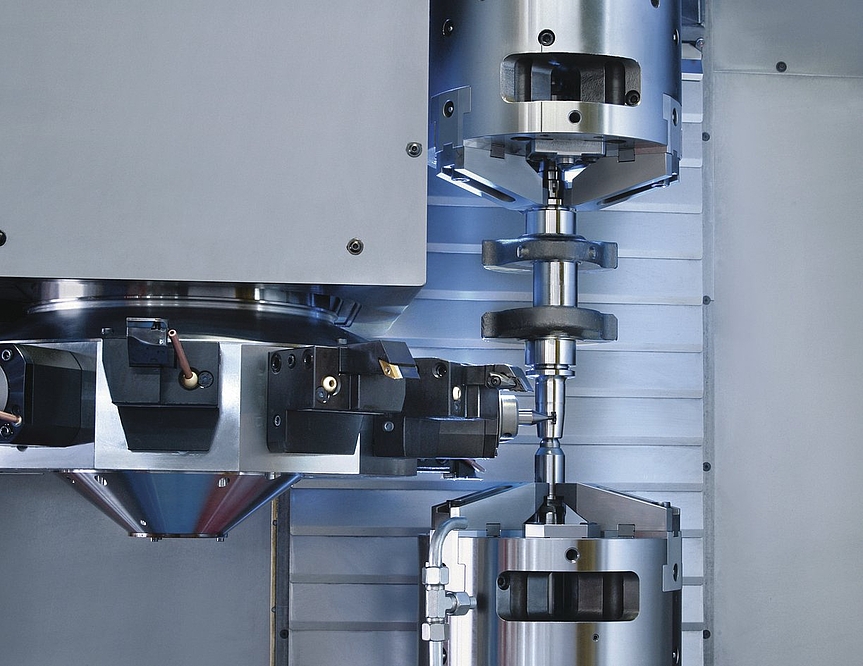

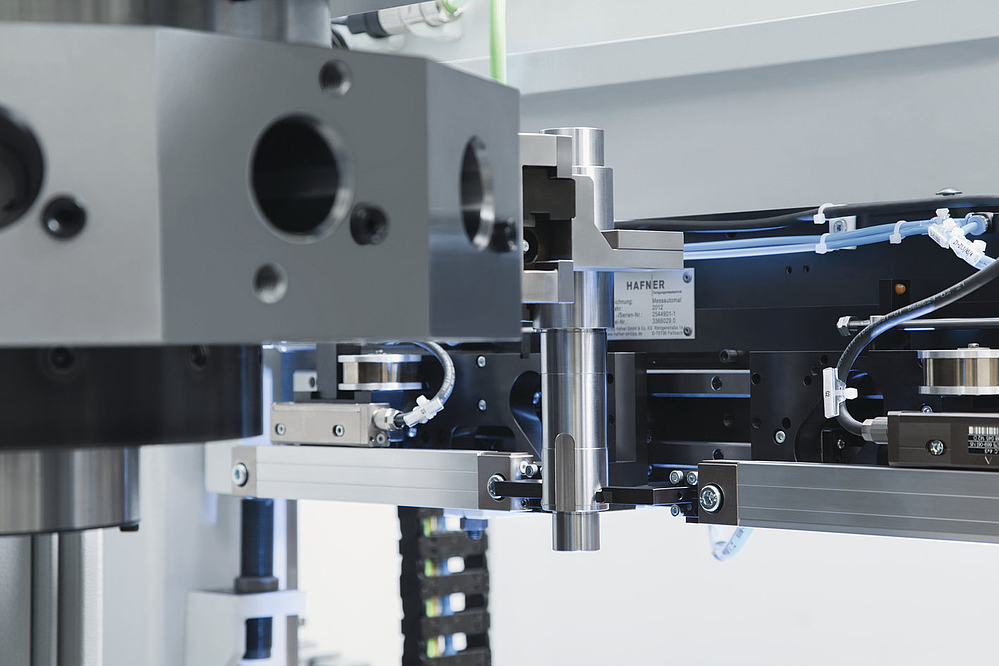

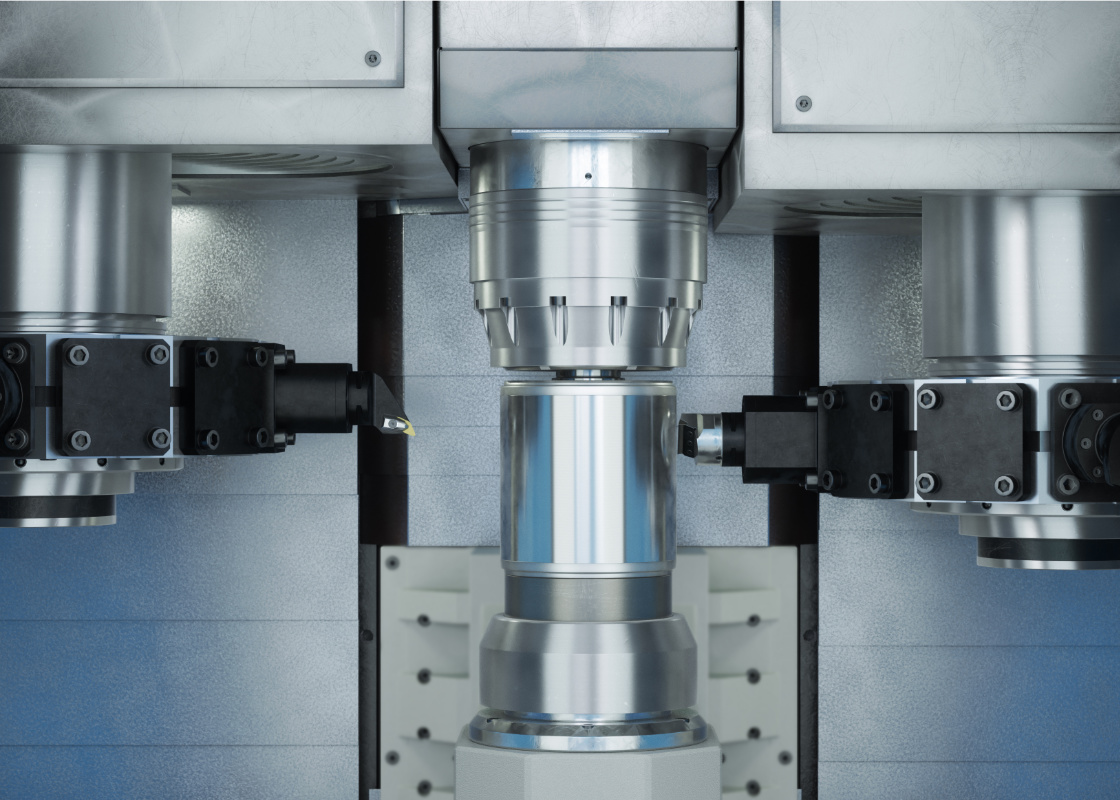

The VTC series of turning centers are specially designed for the vertical machining of shafts, thus turn yet another traditionally horizontal machining process on its head. Users of these vertical turning machines profit from minimal throughput times, true process capability and outstanding precision. The machines provide for the complete-machining of shafts on a single machine with automation included. Technology modules ensure that VTC machines can be customized to suit individual requirements.

The Vertical Turning Centers of the VTC Series Turn Shaft Machining on its Head

Available with a single spindle or in its DUO version, the four-axis VTC 250 machines workpieces up to 140 mm in diameter and 630 mm (optionally 1000 mm) in length. The DUO version combines the functions of two four-axis turning centers and offers different machining technologies on its two stations.

Advantages VTC 250 / 250 DUO

- Four-axis machining reduces cycle times

- Cycle time- simultaneous loading and unloading of the workpieces reduces idle times

- The compact design makes for a small footprint

- Lower capital outlay for automation and peripherals (raw-part and finished component storage sectors form an integral part of the machine)

- Less manual intervention (tailstock and steadies are CNC-controlled; the operator has direct access to the turrets)

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Scroll-free turning technology developed by EMAG offers new possibilities for fine machining. With scroll-free turning, you are able to produce…

Technical Data

Workpiece dia., max.

140 mm

5.5 in

Workpiece length, max.

1,000 mm

39.5 in

Chuck dia., max.

280 mm

11 in

| Workpiece dia., max. |

mm

in |

140

5.5 |

| Workpiece length, max. |

mm

in |

1,000

39.5 |

| Chuck dia., max. |

mm

in |

280

11 |