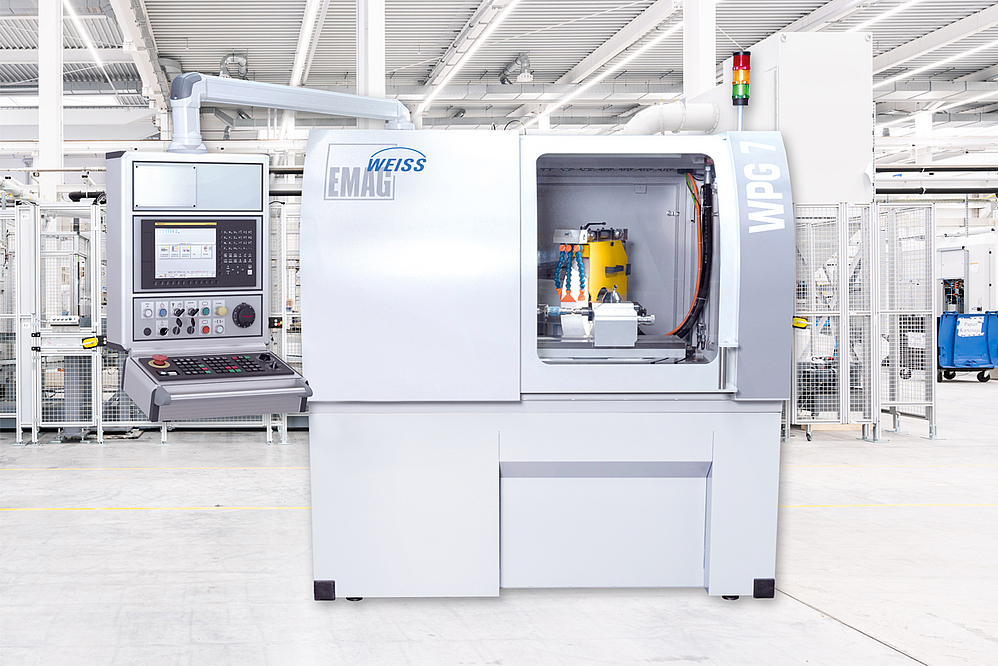

Universal Cylindrical Grinding Machines

WPG 7

- Workpiece length, max.: 250 mm | 10 in

- Center height: 100 mm | 4 in

- Center length: 380 mm | 15 in

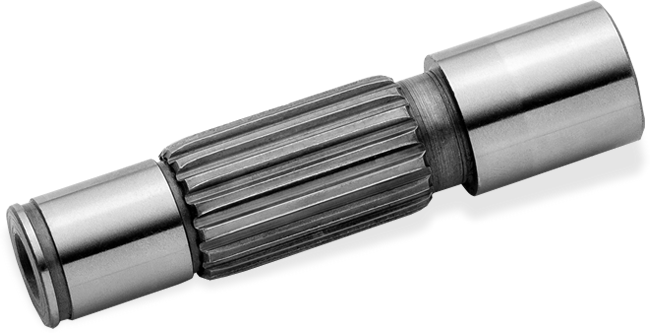

For small shafts, pinions and much more

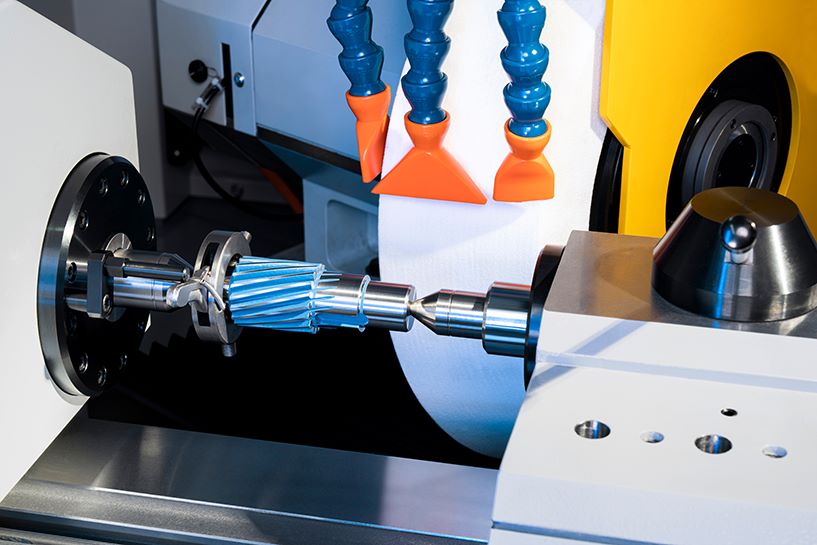

For example, do you want to cylindrically grind small shafts or pinions (up to a workpiece length of 250 mm) at one-second intervals - and with a machine that takes up less space? Here is the perfect solution: The WPG 7 external cylindrical grinding machine from EMAG WEISS scores points with a very powerful grinding wheel drive, a large grinding wheel, simple operation based on a Fanuc control system and optional automation.

Six Reasons for Ordering this Machine

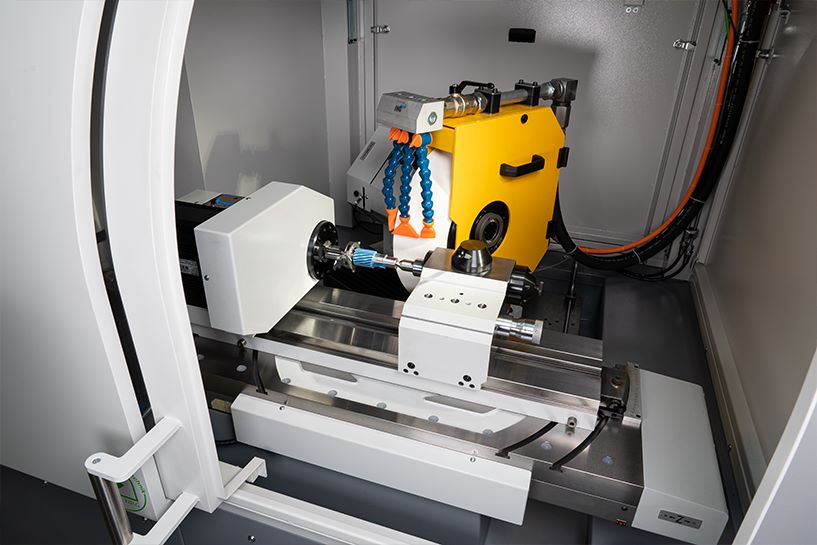

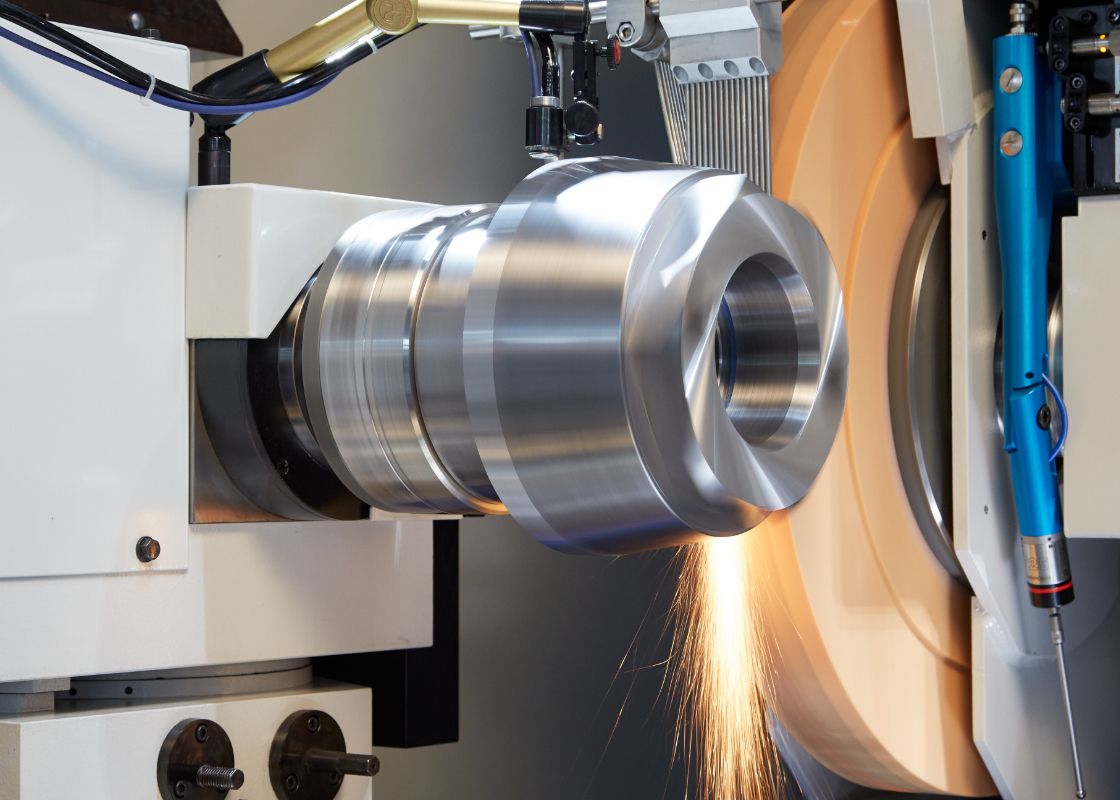

1. Precision and Process Reliability

The machine’s ridged design ensures exceptional component quality by eliminating disruptive vibrations and optimally transferring heat. Options also include high-precision, in-process measurement; passive longitudinal positioning; an automatic balancing system as well as GAP and crash control.

2. With Speed

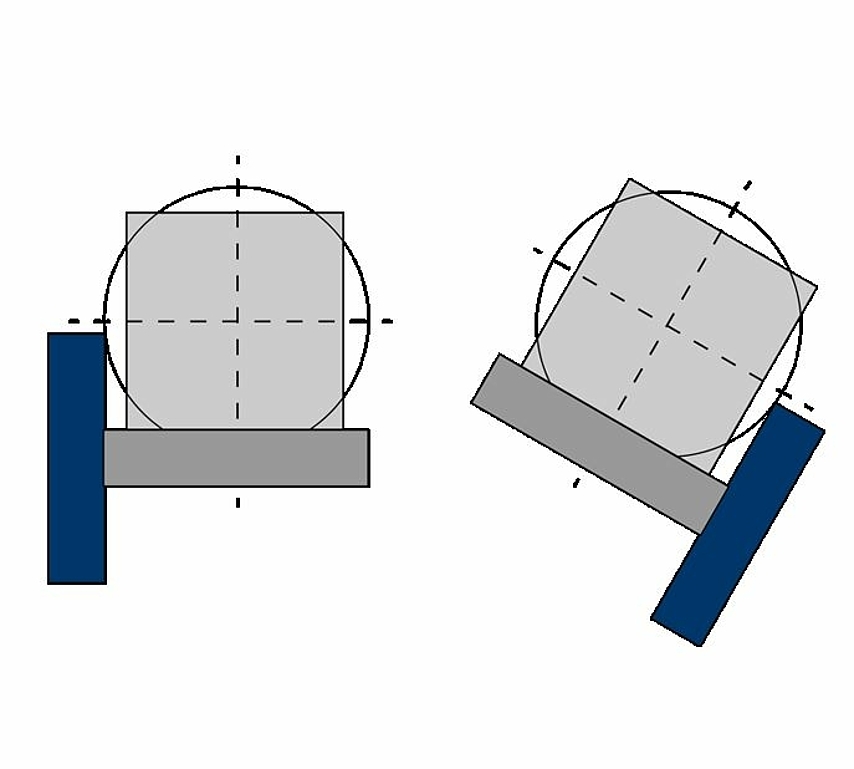

The WPG 7 external cylindrical grinding machine is available in two versions for straight grinding or angular plunge grinding (30 degrees). In both cases, the powerful grinding wheel drive with up to 50 m/s and the large diameter of the grinding wheel (CBN or corundum) of up to 500 millimetres score points. Both ensure enormous speed.

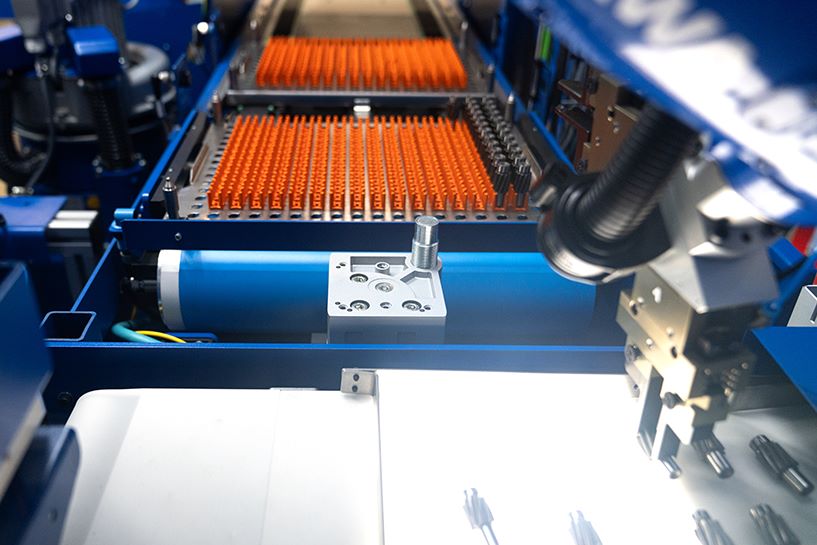

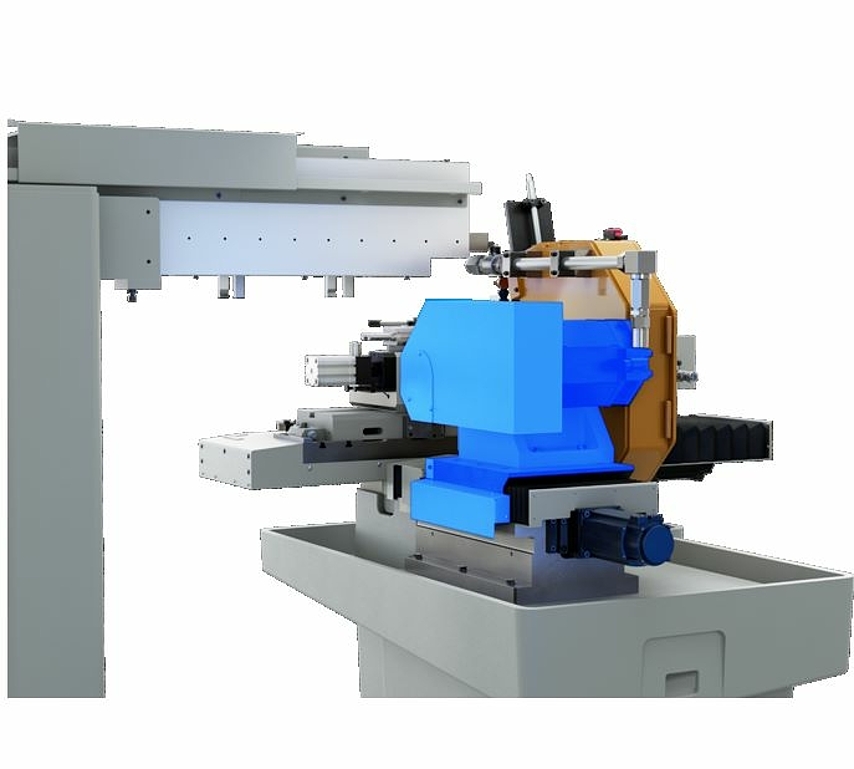

3. Automated

EMAG WEISS offers the cylindrical grinding machine with automation as well as manual loading. Many automated systems such as chain conveyors, pallet circulation or robots can be implemented, using a separate linear gantry including gripper for this purpose. It is virtually integrated into the enclosure and linked-up with the conveyor belt and the like. The changeover times are minimal.

4. Simple

The control panel greatly simplifies the input of technology parameters for a specific cylindrical grinding cycle - just a few parameters are enough. The machine already includes all common grinding cycles in its basic scope.

5. All in One

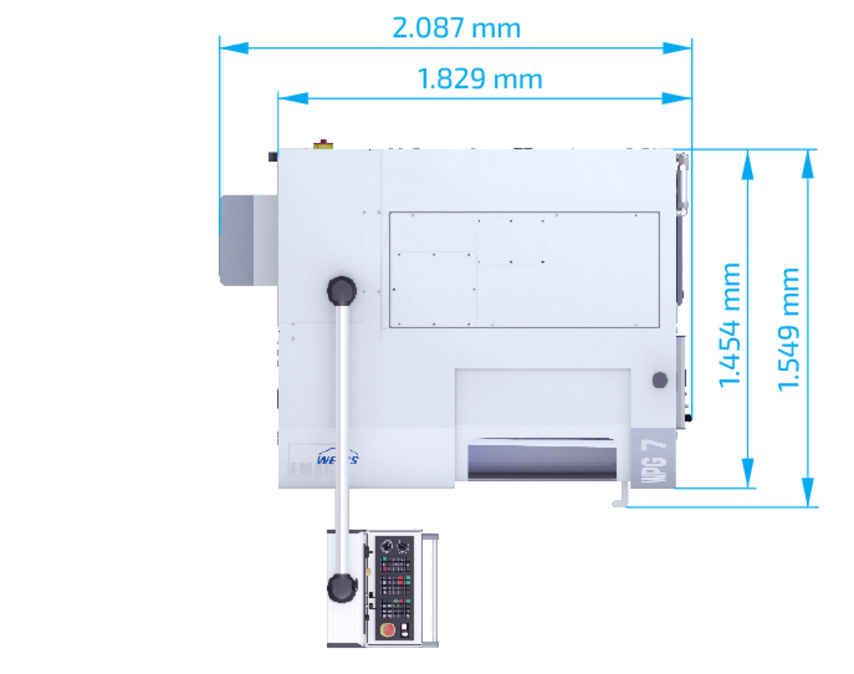

Are you using oversized universal cylindrical grinding machines for machining smaller components? That is often uneconomical! In contrast, the WPG 7 is extremely compact. Everything needed is located within just under four square meters - from the electrical cabinet to the lubrication and cooling system.

6. Ready in no time at all

The hook machine fits on two Euro pallets, making it very easy to transport to the site. Our experts simply connect the power and compressed air. That's it! This process usually takes less than four hours. No major adjustments or new settings are necessary.

Advantages WPG 7

- Available as a 0° straight stitch or 30° diagonal stitch machine

- High-speed grinding wheel drive up to 50 m/s

- Grinding wheel diameter with max. 500 x 80 mm

- CBN or corundum wheels can be used

- Fanuc control

- Cooling system with water or oil

- Minimum footprint of only 1,800 x 2,400 mm

- With stationary and moving tip MK4

- Optional in-process measurement control (diameter), passive longitudinal positioning, automatic balancing system as well as GAP and crash control

- All common grinding cycles integrated in the control system

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Universal cylindrical grinding generally refers to the cylindrical grinding process applied to the outside or inside diameter of a part. For external…

Visit the EMAG Blog for more Information

What characterizes the WPG 7 in detail? Our grinding expert Andreas Holstein provides the answers in this interview.