Production VSC

VSC 400

- Workpiece dia., max.: 340 mm | 13.5 in

- Workpiece length, max.: 160 mm | 6.5 in

- Chuck dia., max.: 400 mm | 15.5 in

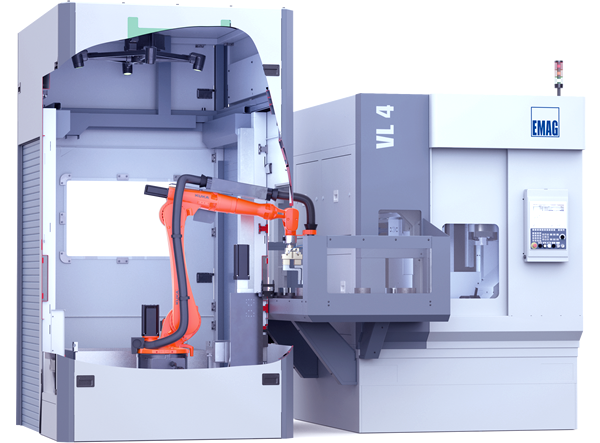

Lathe for the Automated Machining of Chucked Components

The VSC 400 turning machine with vertical turning technology can process round parts with a chuck diameter up to 315 / 400 mm.

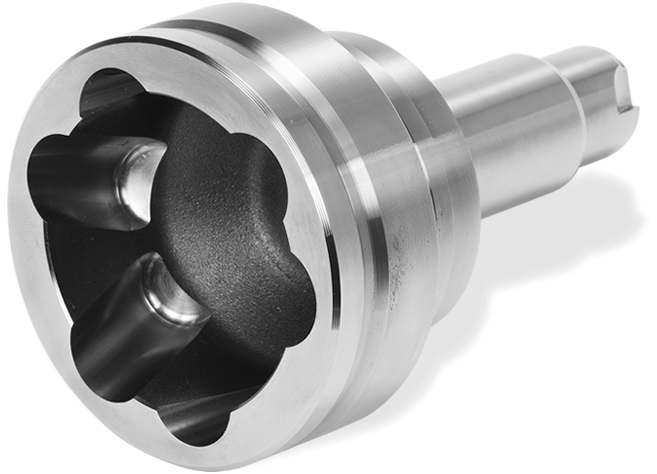

The advantages of the solid vertical construction of the VSC 400 lathe become apparent in the production of gears, chain wheels, couplings, components for CVTs, hinge pins, conrods, rocker arms, bearing rings or piston rings. The vertical layout of the VSC 400 lathe offers highly favorable chip flow conditions that make even dry machining an uncomplicated process.

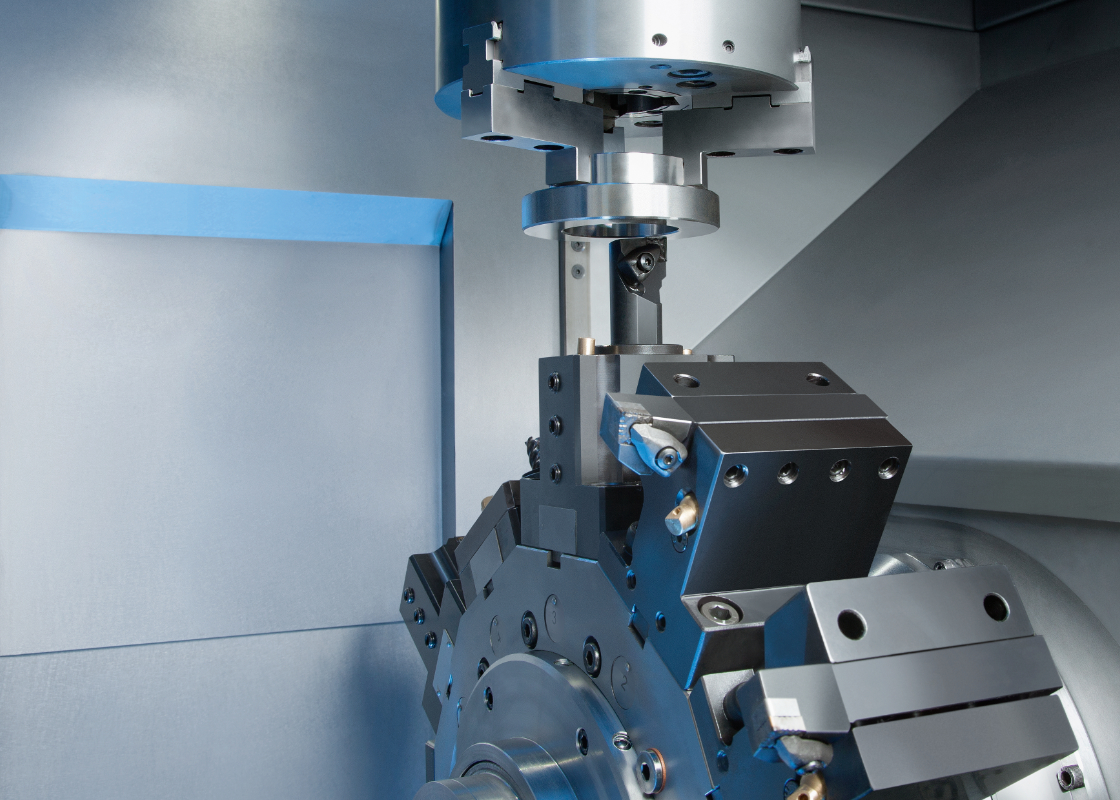

All machine modules, including the machine base of MINERALIT® polymer concrete and its integrated tooling systems, are a rigid, vibration-resistant design.

Machining + Automation + Measuring: The VSC 400 Vertical Pick-Up Lathe Equipped to Suit Production Requirements

Vertical turning, hard turning, drilling/boring, grinding, milling, gear cutting, honing – all on a single lathe. With a large selection of available technology modules, the VSC 400 lathe can be equipped to suit individual machining requirements with impressive productivity and exceptional precision in medium and large batch production.

A variety of linking and automation components allow for these machine to be easily integrated into production lines.

Advantages VSC 400

- Every machine is a production cell that utilizes the pick-up spindle to load itself

- Short travel distances and machining times

- Multifunctional production tool: turning, drilling, milling, grinding and other processes

- The workpiece travels while the tooling systems remain stationary

- Ideal chip flow conditions since the tools are located below the workpiece

- The work spindle with a hydro-static guideway in Z-axis (optional) ensures outstanding component quality and a high tool life for soft and hard machining operations

- All accuracy defining machine assemblies are fluid-cooled

- Safe, wear resistant, maintenance-free machining area envelope

- Dry machining is easy with the VSC as the work spindle and tools are ideally positioned for the process

Manufacturing lines

Complete Manufacturing Lines or Automation Systems from EMAG

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Drilling is one of the oldest production methods and has been used by humans since the Stone Age.

Scroll-free turning technology developed by EMAG offers new possibilities for fine machining. With scroll-free turning, you are able to produce…

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process…

Technical Data

Workpiece dia., max.

340 mm

13.5 in

Workpiece length, max.

160 mm

6.5 in

Chuck dia., max.

400 mm

15.5 in

| Workpiece dia., max. | mm in | 340 13.5 |

| Workpiece length, max. | mm in | 160 6.5 |

| Chuck dia., max. | mm in | 400 15.5 |

We're here for you

Do you have questions or need more detailed information? Please contact us!

To contact