11/04/2020 - Oliver Hagenlocher - Press

LC 4-2 Laser Cleaning Machine: Focused on Fast Cleaning Processes and Optimizing Component Surface Quality

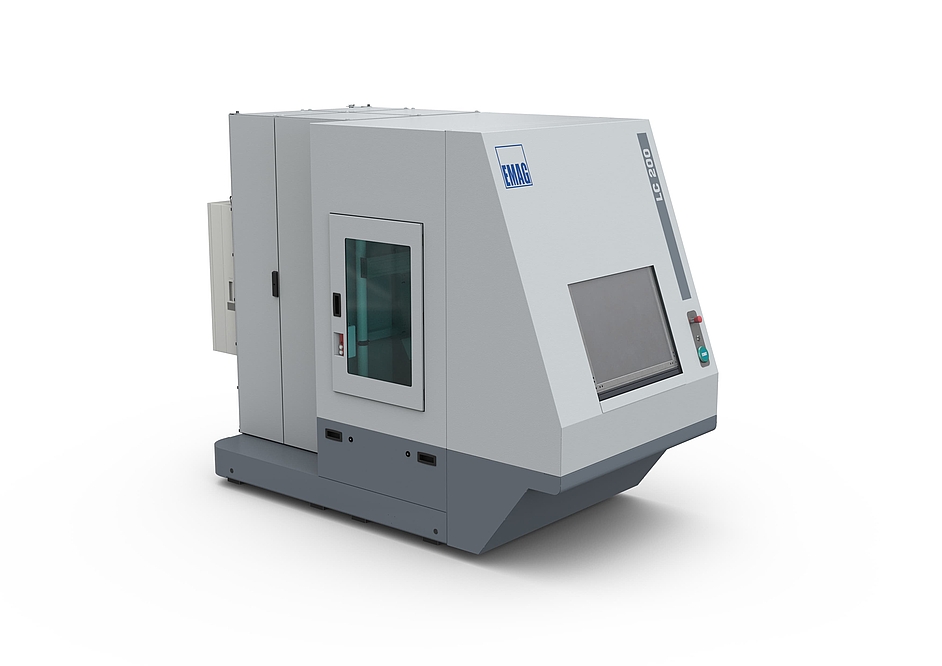

The need for industrial cleaning processes is not uncommon – many parts are contaminated with substances including oil and adhesives, or have undesired layers of oxide, rust, phosphate, or paint that needs to be removed before additional machining processes can take place. With that in mind, production planners are turning their attention to the efficient laser cleaning and coating removal processes. With the new LC 4-2 laser cleaning machine, the specialists at EMAG LaserTec are continuing to advance these technologies: The LC 4-2 provides low-maintenance component cleaning in a very small space, can be implemented as a manually loaded standalone solution or fully automated in a production line, and scores highly for its reliable and reproducible results. The technology can also be used for surface functionalization, for example, to improve surface wettability. What distinguishes EMAG mechanical engineering in this field?

Images

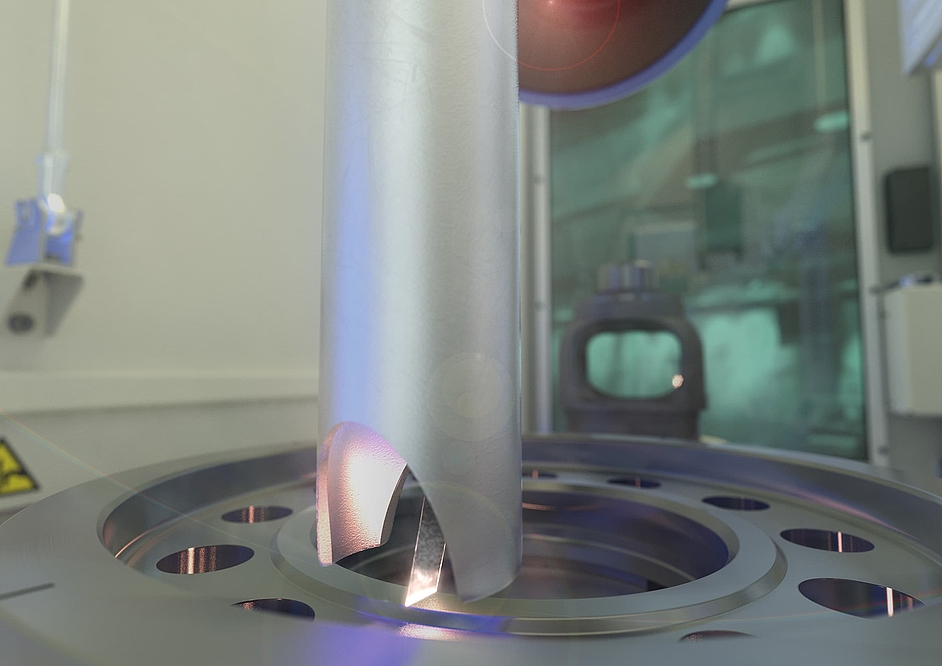

The basic principle of laser cleaning is fascinating: Pulsed laser radiation strikes a surface at high pulse peak power. The material instantly evaporates and only a very thin layer is heated in the process. Many types of impurities or coatings can be removed from a component pulse by pulse in this manner—from coolants or oils, to oxide and graphite layers to rust, paint, and phosphate layers. The technology is also used to prepare surfaces for subsequent work steps (e.g. “roughing”). In short, the process is extremely flexible and very energy efficient. However, the associated mechanical engineering relies on know-how, emphasizes Nikolas Meyer, sales manager at EMAG LaserTec. “Key process parameters, such as processing time, must be adjusted according to the task at hand—as simply as possible, using a machine control. Otherwise, the implementation becomes too complex for day-to-day operations. The technology must also be extremely flexible—for example, it must work as a standalone solution or within a production line. With our LC 4-2 laser cleaning machine, we meet this and other requirements using our proven EMAG modular technology. Our solution is extremely reliable, efficient, and saves space.”

The laser specialists within the EMAG Group benefit from the group's vast experience: Turnkey laser welding systems for lightweight construction of sophisticated powertrain components have been produced at the site in Heubach, near Schwäbisch Gmünd in southern Germany, for about 15 years. This expertise was effectively put to use in the development of the laser cleaning system for components up to 200 millimeters (8 in) in diameter and 350 millimeters (14 in) in height. Five key requirements played a decisive role in this:

1. Can be Integrated in Production Line or as Standalone System

A complex production process such as “laser welding of differentials” comprises several additional processes, from induction heating (if required) and joining, to laser welding and all the way to final process control. However, it always begins with a cleaning process, because the ring gear and the differential case must have phosphate layers and contamination removed. The specialists at EMAG had this and similar applications in automotive mass production in mind when they developed the LC 4-2. Therefore, the machine can be integrated in end-to-end production lines, or used alone. For this reason, it features a turntable separate from the workarea, and can be loaded/unloaded by an automation system (or manually) without interrupting the operation. As an option, two components can be clamped simultaneously, while two others are run through the cleaning process – resulting in shorter throughput times. There are no idle times or interruptions in the material flow.

2. Process: High Reliability Guaranteed

A fundamental advantage of this technology is the use of sharply focused “light” during cleaning. In the case of the LC 4-2, this is achieved by a high-efficiency 200-W laser that is only switched on for a few seconds for each component. In production lines, it is particularly important that the laser beam be positioned with high process reliability. As an alternative, the cleaning lens can be positioned manually. The optional “EMAG EC Clean” software documents all process data and provides support in error management.

3. Flexibility: Suitable for Many Tasks

The laser technology in the LC 4-2 is suitable for a variety of materials and for entirely different tasks. The short pulse duration plays an important role in this by ensuring short interaction time, and minimizing surface damage. The short pulse duration also enables high pulse peak power, which can be used to achieve certain surface properties such as improve adhesiveness.

4. Costs: Small Footprint and Short Processing Times

Compared to conventional industrial washing systems, laser cleaning with the LC 4-2 leads to lower unit costs. The machine’s small footprint is one aspect that contributes to this: It only needs 4.5 square meters (48 sqft) of floorspace. Another is that the laser is only on for a few seconds at a time and is virtually maintenance-free. The entire cleaning process or surface treatment is fully automated and only takes a few seconds. In contrast, conventional cleaning systems often require around 20 square meters (215 sqft) of floor space and must always be running and consuming energy to keep the washing fluid at a certain temperature. They also require additional drying and flushing processes that slow down the entire production process.

5. Environment: Green Technology

An additional advantage of laser cleaning is its low environmental impact—particularly in comparison to wet-chemical washing processes with cleaning agents that must later be disposed of. Cleaning agent residues on the component can also lead to problems in subsequent production processes. No washing agents are required for laser cleaning.

EMAG Mechanical Engineering Excels

“All in all, we’ve put together a very flexible and powerful comprehensive package,” concludes Nikolas Meyer. “The machine can be used both autonomously and within an automated production line. It only requires a little space, can easily be configured for different tasks, and ensures lower unit costs with its efficient laser and loading concept. We are very optimistic that this technological approach will establish itself well in the market. The technology is particularly interesting for high-volume welding or bonding applications in the automotive, aerospace, medical or electronics industries.” The modularity of EMAG mechanical engineering is bound to be one of the decisive success factors: The South German mechanical engineers create their customer-specific system solutions with “building blocks.” This means that the high-quality components used are well proven. This also applies to the LC 4-2 laser cleaning machine.

LC 4-2: Advantages at a Glance

- Low energy consumption and low maintenance

- Can be integrated into production lines or used as a standalone solution

- Small footprint

- Stable process—not dependent on water quality and additives (in comparison to washing processes)

- Eliminates nearly all contamination and coatings

Contact

Oliver Hagenlocher

Area

Press and Communication