Archive

12/02/2019 - Oliver Hagenlocher - Press

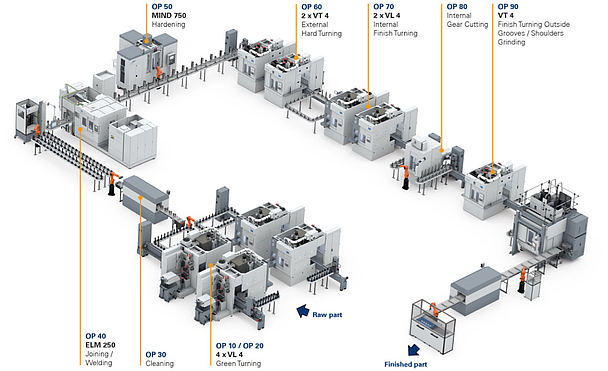

Production System by EMAG: Lightweight Rotor Shafts Machined with End-to-End Production SystemsA large number of studies are predicting rapid growth in e-mobility. The latest sales figures confirm the trend: According to the Center of Automotive Management, sales of electric cars in China and the USA increased dramatically last year. In…

11/07/2019 - Oliver Hagenlocher - Press

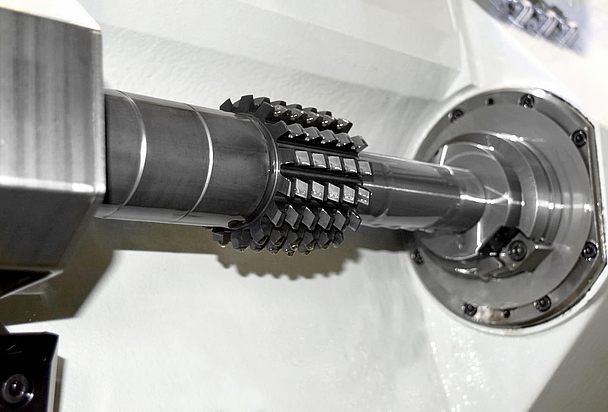

R 300 Hobbing Machine from EMAG Richardon: HKS Dreh-Antriebe Invests in High-Efficiency Gear Cutting ProcessesRotary actuators are jacks-of-all-trades: They are implemented whenever an object must be rotated or swiveled—this is necessary during the production of utility vehicles, ships, machines, power plants, and production areas. This broad range of uses…

10/14/2019 - Oliver Hagenlocher - Press

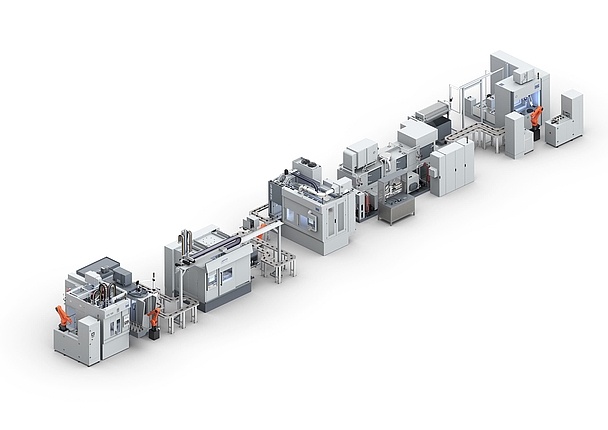

EMAG Production System: Perfecting the Finish-Machining of Turbocharger ShaftsThe production of turbochargers is one of the most demanding tasks in automotive engineering: High-strength materials, precise geometric requirements, large quantities and price pressure are key challenges for OEMs and suppliers. The continual…

08/23/2019 - Oliver Hagenlocher - Press

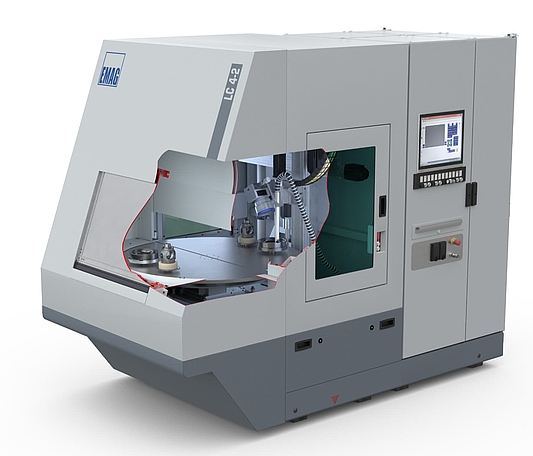

Laser Cleaning Machine of EMAG LaserTec: LC 4-2 Laser Cleaning Machine for implementation in Manufacturing Lines or as a Standalone MachineEMAG LaserTec is known first and foremost for highly productive laser welding systems. The focus is indeed on the word “system”: In addition to the actual welding process, steps that occur upstream or downstream of the welding are frequently…

08/20/2019 - Oliver Hagenlocher - Press

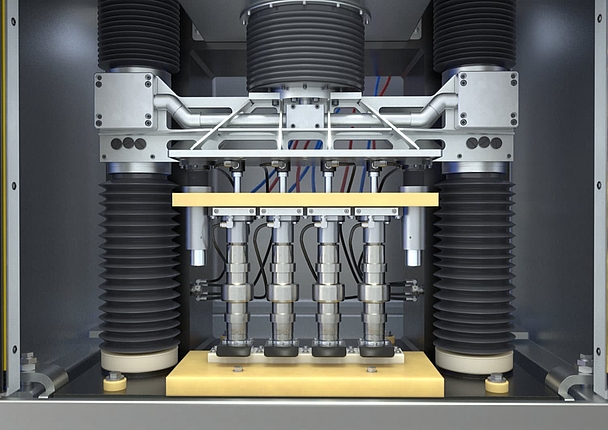

PI 800—Modular ECM / PECM Machine: Completing complex machining tasks very efficiently with an electrochemical processAnyone who has had a closer look at the ECM process knows that it is an innovative technology. In order to make manufacturing with PECM even more accessible, EMAG ECM, headquartered in Gaildorf, near Schwäbisch Hall in Germany, has developed a new…

08/12/2019 - Oliver Hagenlocher - Press

The new MIND-L 1000 from EMAG eldec: Lower cost of investment and increased productivity in induction hardeningPrecisely timed cycles, extremely accurate heating patterns and perfect integration in the production process—the advantages that induction hardening provides propel the implementation of the process in many application areas in the automotive…

08/07/2019 - Oliver Hagenlocher - Press

New DUO Machine for Series Production: The VL 5 DUO from EMAG delivers a boost to the Production of Powertrain Components up to 250 mmThe success story of DUO machines from the EMAG Modular Solutions product family keeps on going. At the EMO in Hanover, EMAG will present the latest expansion stage of the DUO series, the VL 5 DUO. What can users expect from the new machine? In a…

08/06/2019 - Oliver Hagenlocher - Press

EMO 2019 – Complete Production Solutions with the VL 1 TWIN: Massively reduce unit costs for planetary and bevel gearsCost pressure, high quality requirements and demand for huge output volumes—extremes collide in automotive transmission manufacturing. While meeting these demands, production quantities will also projected to continue to rise in the coming years. The…

07/02/2019 - Oliver Hagenlocher - Press

EMAG at the EMO 2019 in Hanover: The Sequel to a Successful Event ConceptWhat does the automotive future hold? This question is one way you could briefly summarize the motto of the EMAG Group's 2019 Technology Forum held at its headquarters this May.

The technology forum is traditionally held in the same year as the EMO…

06/05/2019 - Oliver Hagenlocher - Press

Solid-State Versus Gas Lasers – Modern Laser Production Technology for Powertrain ComponentsEven a few years back major manufacturers utilized standard CO2 lasers in factories for welding applications. Massive systems installed in separate rooms away from the actual production process supplied the energy for what, at the time, was…

05/29/2019 - Oliver Hagenlocher - Press

Experts advised about the revolution in the automotive industryBuzzwords such as “e-mobility,” “autonomous driving” and “big data” outline a fundamental shift in the global automotive industry that comes with far-reaching changes to production—constituting a major challenge for the underlying mechanical…

05/20/2019 - Press

EMAG wins the “Axia Best Managed Companies Award”Strategic vision, capacity to innovate, sustainable management culture and good corporate governance—the “Axia Best Managed Companies Award” sets expectations high for participating businesses. This year, the organizers from the consulting firm…

02/06/2019 - Oliver Hagenlocher - Press

EMAG Automation becomes EMAG LaserTec: Driving laser welding and joining technology with a new nameEMAG laser welding technology has been an impressive success story for years: The system ensures efficient light construction and lower component costs in the manufacture of numerous vehicle components. The relevant turnkey production systems are…