08/07/2019 - Oliver Hagenlocher - Press

New DUO Machine for Series Production: The VL 5 DUO from EMAG delivers a boost to the Production of Powertrain Components up to 250 mm

The success story of DUO machines from the EMAG Modular Solutions product family keeps on going. At the EMO in Hanover, EMAG will present the latest expansion stage of the DUO series, the VL 5 DUO. What can users expect from the new machine? In a nutshell: Everything is getting bigger!

Images

When EMAG introduced the VL 3 DUO double-spindle pick-up turning center in 2016, it quickly became clear: This is where EMAG excels in the market. With a parts range up to 150 mm in diameter, the VL 3 DUO is ideally suited for the production of gear components, such as ring gears, car wheel hubs, differential housings or taper disks.

(Here you can see the VL 3 DUO in a video: https://www.youtube.com/watch?v=MrdFMU5GFPM).

Following the great success of the machine, calls were soon becoming louder for the next expansion stage in order to efficiently process even larger components with the DUO concept, i.e. two operations (OP 10/OP 20) in the same machine. It was time for something bigger.

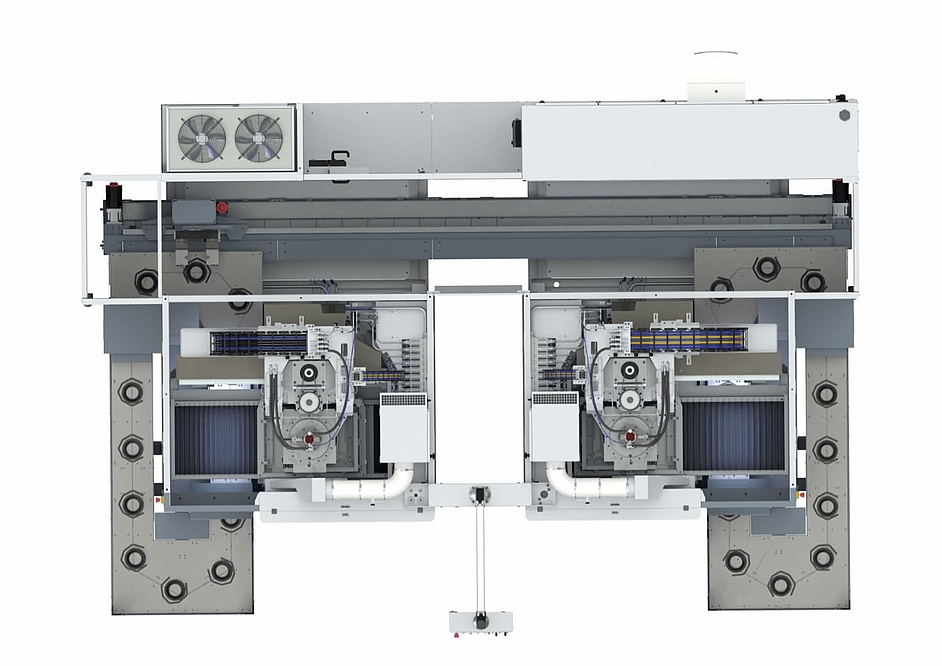

With the VL 5 DUO, EMAG is now presenting the proven DUO concept for a range of parts up to 250 mm, which is exactly the target of production planners for the entire range of powertrain components.

What users can expect from the VL 5 DUO

If you ask Björn Svatek, EMAG Sales and Marketing Director Modular Solutions, about the features of the VL 5 DUO, his answer is clear: "Basically, I only need to refer to the VL 3 DUO. We took everything that makes the VL 3 DUO unique, and transferred it to the VL 5 DUO: Flexibility, quality, automation technology – all of these are also found in the VL 5 DUO, only bigger."

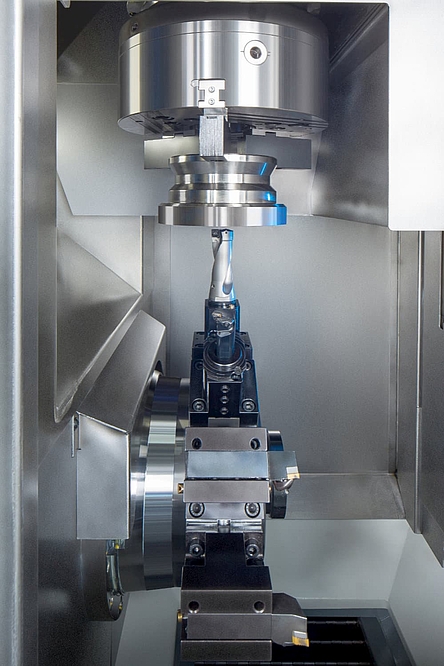

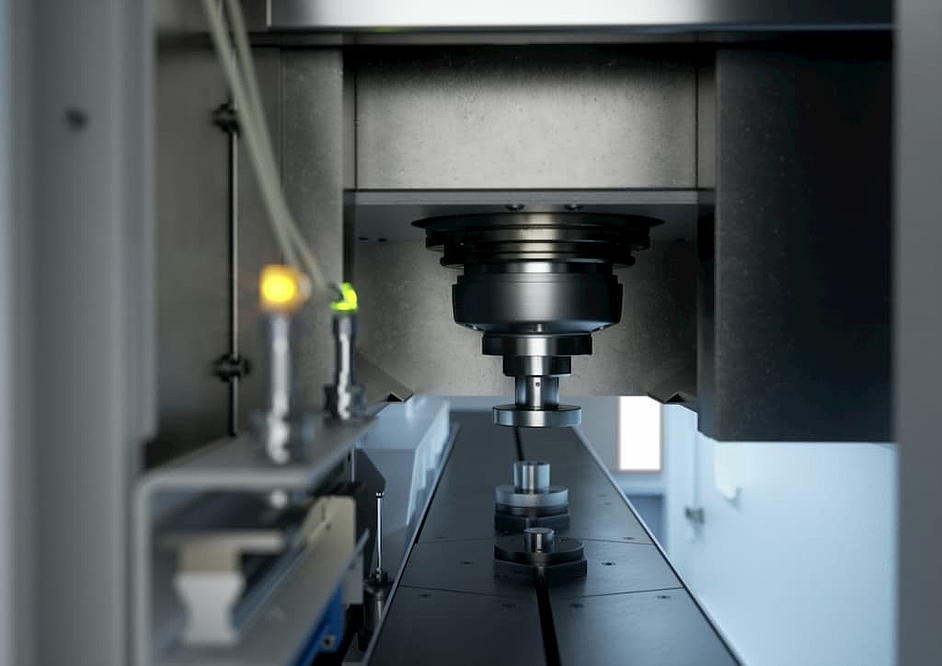

Keyword Flexibility: The VL 5 DUO has two mirrored machining areas, each with its own motor spindle with up to 34.1 kW power and 593 Nm torque at 40% duty factor. In addition, each machining area is equipped with an EMAG tool turret with twelve tool posts, which can be equipped both with turning tools and with driven tools. The water-cooled turrets are a trademark of EMAG and are characterized by maximum thermal stability. The turrets can also be equipped with an additional Y-axis, further extending the machine's range of applications.

With this configuration, the VL 5 DUO can be used in a wide variety of production scenarios: Either as a single-machine solution for OP 10 and OP 20 with complex machining processes, which can be performed easily thanks to the extensive tool magazine of 12 tool posts for each machining area,or as a high-productivity solution with fast cycles for line production, OP 10 and OP 10, in which the tool posts are equipped with sister tools, thus maximizing machine uptime between tooling operations.

With this configuration, the VL 5 DUO can be used in a wide variety of production scenarios: Either as a single-machine solution for OP 10 and OP 20 with complex machining processes, which can be performed easily thanks to the extensive tool magazine of 12 tool posts for each machining area. Or as a high-productivity solution with fast cycles for line production, OP 10 and OP 10, in which the tool posts are equipped with sister tools, thus maximizing machine uptime between tooling operations.

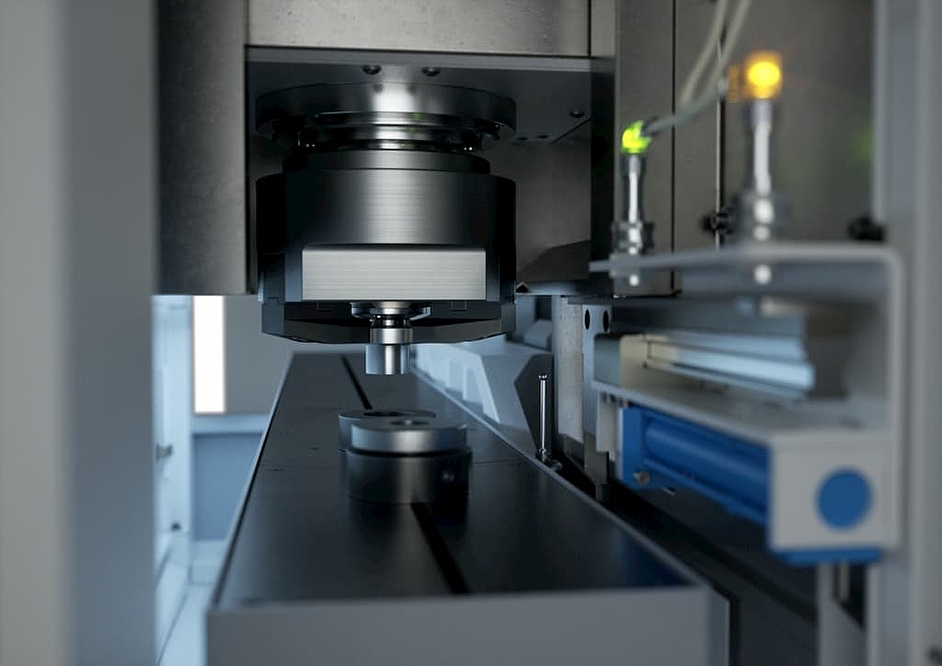

Keyword Quality: The machine base of the VL 5 DUO is cast from MINERALIT® – a polymer concrete with optimum vibration-damping properties. In this machine base, all production units, such as spindles and tool turrets, are mounted with maximum stability. In addition, there are size 45 recirculating roller guide rails, and a direct distance measuring system in all linear axes. This guarantees maximum continuous positioning accuracy and repeatability for the VL 5 DUO. If required, a measuring probe can also be integrated into the machine to allow fast component measurement between loading and unloading of workpieces.

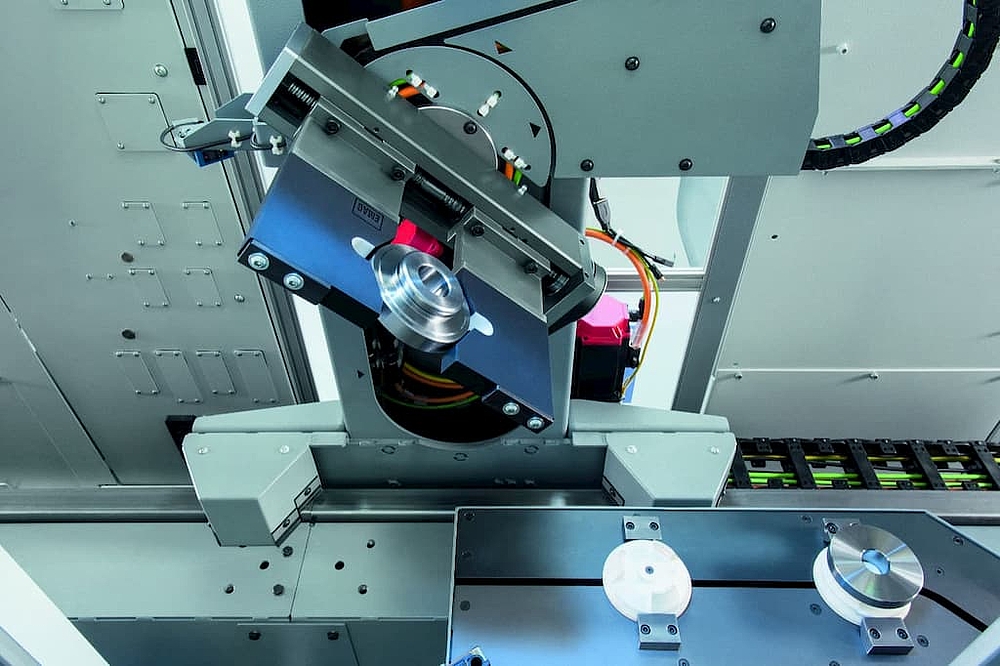

Keyword Automation: Each Modular Solutions machine has an integrated automation concept. The VL 5 DUO is no exception and is equipped with a pick-up automation system, which enables automated loading from its own parts buffer by means of a pick-up spindle. The TrackMotion automation system completes the integrated automation. On the parts buffer, it loads the single-part pallets that travel back and forth between the loading positions next to the machining area, and the rear part of the machine. This can be clearly observed in the video mentioned above, starting from second 50: https://youtu.be/MrdFMU5GFPM?t=50.

TrackMotion and pick-up automation – a perfect team

The TrackMotion automation system is just as flexible as the VL 5 DUO itself. The heart of the system is the TransLift, an NC-operated gripper that not only handles the entire parts transport, but also acts as a flip-over unit between operations. Stacker pallets can be used for the overall parts storage system, enabling the raw and finished parts to be stacked in the smallest possible space. This can be done either on a central storage surface, or by installing a separate parts storage unit for raw and finished parts to the left and right of the machine. This again demonstrates the great flexibility of the overall concept.

Ideal extension of the Modular Series

The VL 5 DUO extends the EMAG Modular Solutions series by a high-productivity manufacturing system for powertrain components in large-scale production. "The VL 5 DUO is already a highly effective production machine in itself. However, same as with all the Modular Solutions series, the unified design of the modular machines with their integrated automation and consistent transfer height makes it much easier to link different technologies such as turning, gear hobbing and deburring. This means that even complete production lines from raw to finished part can be implemented quickly," concludes Björn Svatek.

An in-depth interview with Björn Svatek about the EMO presence of the EMAG Group can be found here.

Downloads

Contact

Oliver Hagenlocher

Area

Press and Communication