11/04/2021 - Oliver Hagenlocher - Press

EMAG SU: High-tech solutions for top component quality when cutting gear teeth

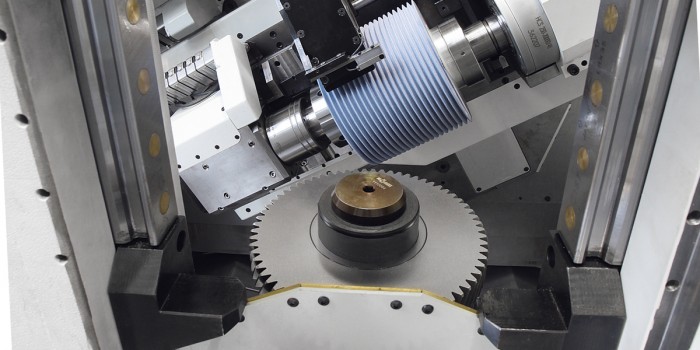

Sectors ranging from the automotive industry, aerospace technology, transmission engineering, and numerous others are going through a technological transformation, with many users requiring increasingly powerful production solutions to reduce their per-unit costs and meet the growing demands for component quality within the micrometer range. In view of this, it is easy to understand why gear cutting technology from EMAG SU (formerly Samputensili) is in high demand all over the world. The Italian machine manufacturer develops high-precision milling, grinding, shaping, and shaving machines, with few companies matching the wide technological variety it offers.

Images

Its specialty is rough and fine machining of gears, shafts, worms, rotors, screw shafts, and other screw-type workpieces. EMAG SU has implemented a whole series of technological innovations for huge improvements in performance, as the example of generating grinding clearly shows: the machines boast short chip-to-chip times, intelligent axis concepts, thermal and mechanical stability, and easy user navigation. With the G 160 for components up to module four with a maximum outside diameter of 160 mm, for example, EMAG SU has the fastest machine on the market. The speed is made possible by two parallel workpiece tables that take turns moving at high speed (with the help of hard-wearing linear motors) to the grinding wheel.

Just as interesting are the profile grinding machines from EMAG SU for machining external and internal gear teeth, rotors, and worms in small and large volumes. What sets the technology apart is its precision, short tooling times, and reliability. This can be seen in action in the G 500 H for components up to module 35 mm with an outside diameter of 500 mm and a length of up to 1,850 mm. It can grind workpieces with internal and external gear teeth with the help of quick-change grinding elements. The long variant GW 7000 H can grind ball screws measuring up to 7 m, for example. This machine can also be equipped with a tool changer, which has great advantages with single-shaft extruder shafts. The GW 3600 HD (4- or 5-axis machine) is designed for economic machining of rotors or worms with a maximum diameter of 500 mm and a length of 2,500 mm. All the machines permit flexible production with short tooling times.

Focus on shaving, chamfering, and deburring

The focus is also on efficient processes when it comes to the shaving machines from EMAG SU. They can perform all shaving processes, depending on the model and axis configuration – from plunge and parallel shaving to underpass and diagonal shaving. The high rigidity guarantees high precision here. At the same time, powerful tool and workpiece axes ensure productivity with varying batch sizes.

The chamfering and deburring machines from EMAG SU for manufacturing spur and helical gears have short cycle times as well, since chamfering, smoothing, and deburring are combined in one process. Self-centering tools guarantee symmetrical chamfers on both sides of the workpiece. The SCT 3 can be easily connected to a wide range of automation systems or robots, and even the standard version has a loading slide for manual loading and unloading.

Success on the market with EMAG Sales

EMAG SU guarantees its customers competitive advantages and a fast return on investment, whether in milling, grinding, shaping, or shaving. It achieves this by continuously investing in research and development to further boost the efficiency and environmental friendliness of its machines. At the same time, EMAG SU benefits from the global reach of the EMAG Group: the machine manufacturer from southern Germany handles the global distribution of the machines and thus lays the foundation for success on the market. All things considered, the specialists at EMAG SU see themselves ideally positioned for the gear cutting applications of the future. For example, in the field of e-mobility, the high torque of the electric motor is directly associated with special dimensional and surface requirements here, which are no problem for the machines from EMAG SU. Several European car manufacturers are successfully using several grinding machines from EMAG SU in this field now.

Downloads

Contact

Oliver Hagenlocher

Area

Press and Communication