External Cylindrical Grinders

HG 208 DW

- Workpiece dia., max.: 200 mm | 8 in

- Workpiece length, max.: 600 mm | 23.5 in

- X-axis travel: 380 mm | 15 in

External Cylindrical Grinding Machines

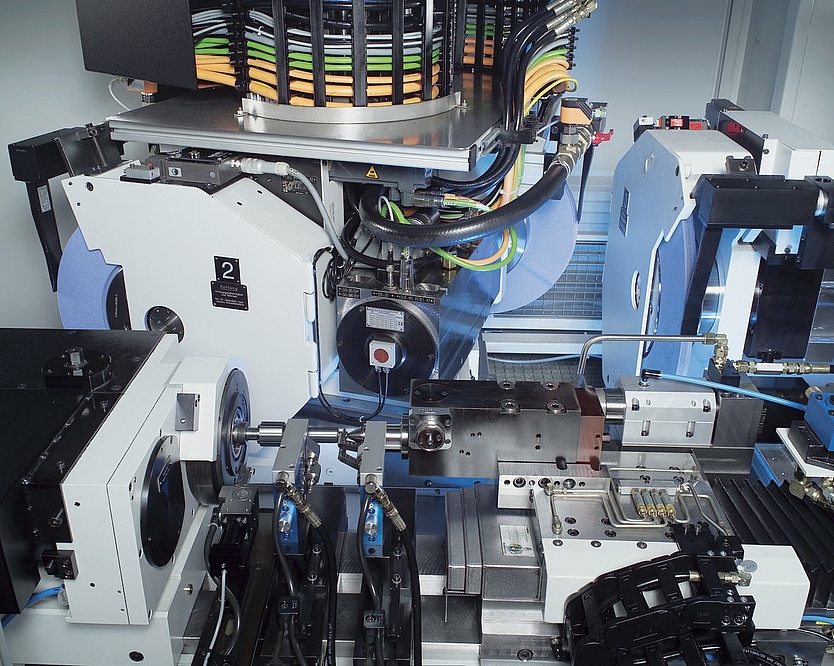

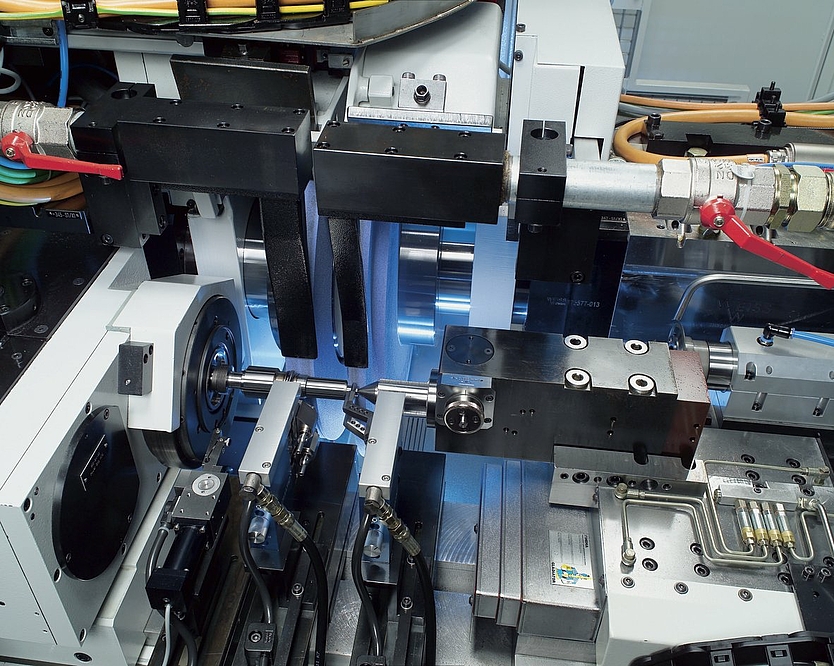

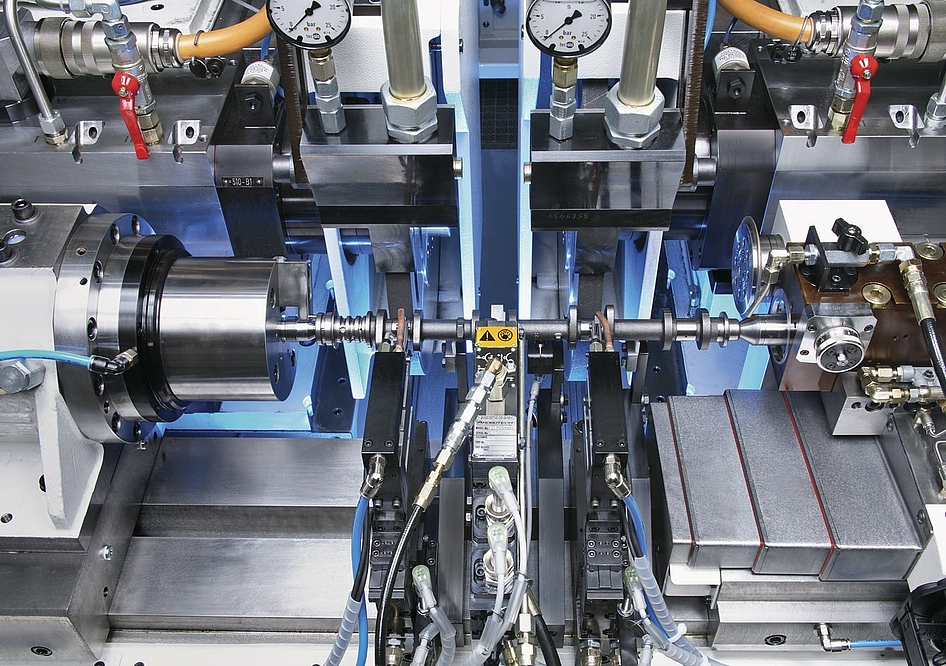

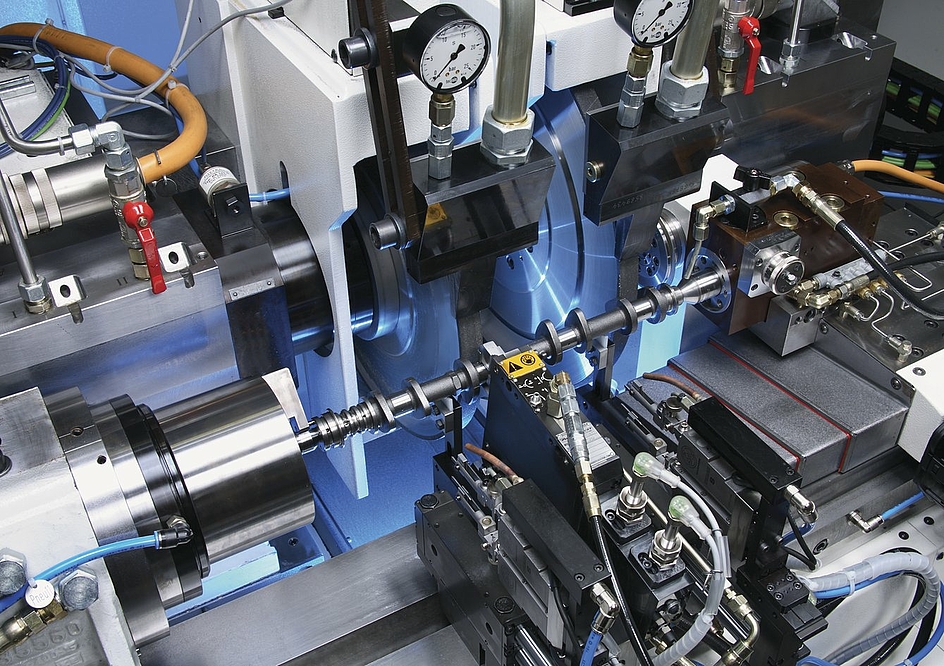

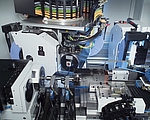

The four-axis HG 208 DW Simultaneous Grinders allows for two external cylindrical grinding operations to be performed simultaneously on shaft-type components.

This method is excellent for workpiece families where the same operations are performed at varying distances to each other. It includes steering pinions, gear shafts, motor shafts and compressor shafts.

Grinders for Simultaneous Machining: EMAG HG 208 DW

The advantages from simultaneous grinding on the HG 208 DW Grinders are:

- High component quality through complete-machining in a single set-up

- Short cycle times

- Economic production of component families

- Low capital outlay per component

Advantages HG 208 DW

- A high-powered wheel drive shortens machining times

- A contact and crash recognition and wheel balancing system monitors the grinding process

- An in-process gauging control checks O/Ds and the longitudinal position on shoulders

- Operator and setter menus simplify handling

- High-precision, sturdy linear roller guiderails in all axes guarantee the longevity of the machine

- Absolute measuring systems (linear glass scales) in all axes ensure machining accuracy

- An NC tailstock with large stroke makes for easy resetting

- Short idle times lead to high productivity levels

- An operator-friendly workpiece error correction system automatically rectifies dimensional errors

- Large doors give optimal access, thus reducing the distance between operator and workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Finding the right balance between flexibility and productivity is challenge of designing machines for cylindrical grinding.

This demand is met with…

Grinding, besides drilling, is one of the best known chip removal production methods because it is also frequently used during daily activities.

Technical Data

Workpiece dia., max.

200 mm

8 in

Workpiece length, max.

600 mm

23.5 in

X-axis travel

380 mm

15 in

| Workpiece dia., max. | mm in | 200 8 |

| Workpiece length, max. | mm in | 600 23.5 |

We're here for you

Do you have questions or need more detailed information? Please contact us!

To contact