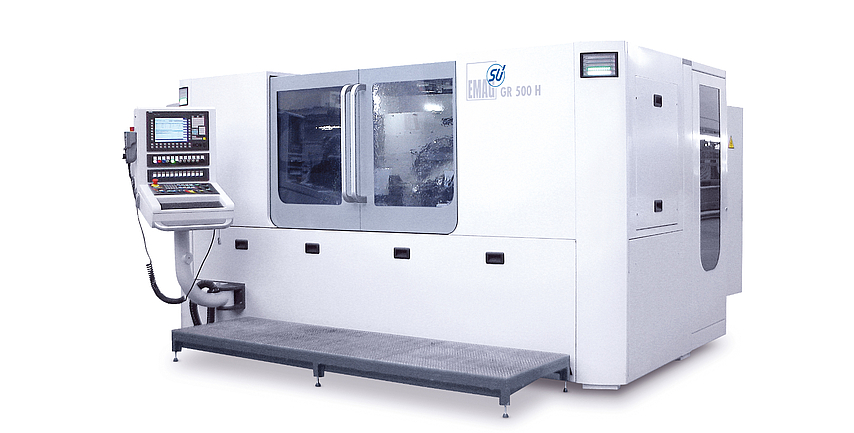

Gear Profile Grinding Machines

GR 500 H

- Module, max.: mm 35.0

- Workpiece dia., max.: 400 mm | 15.5 in

- Workpiece length, max.: 1,250 mm | 49 in

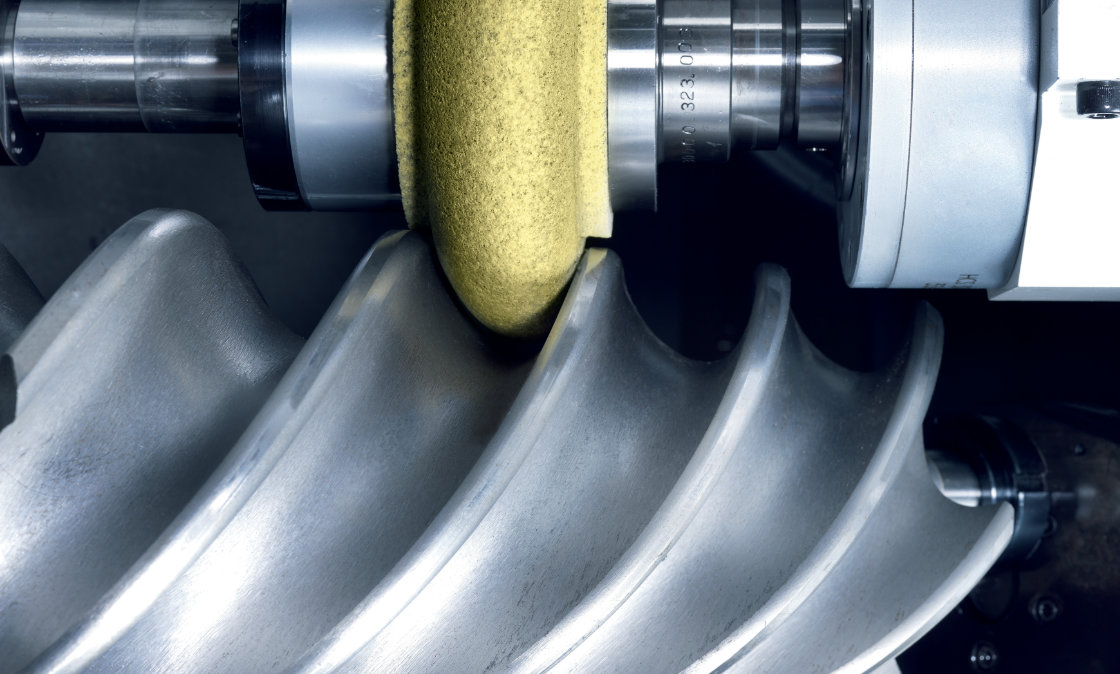

Screw Profile Grinding GR 500 H

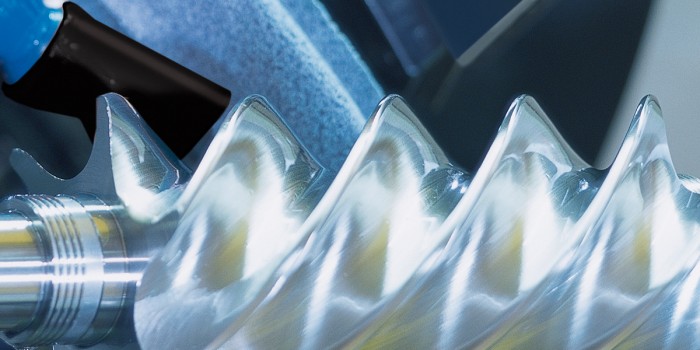

The GR 500 H provides efficient high precision grinding of a wide range of screw-type profiles including worms, ball screws, rotors, hydraulic pump screw.

Efficient High Precision Grinding of a wide Range of Screw-Type Profiles

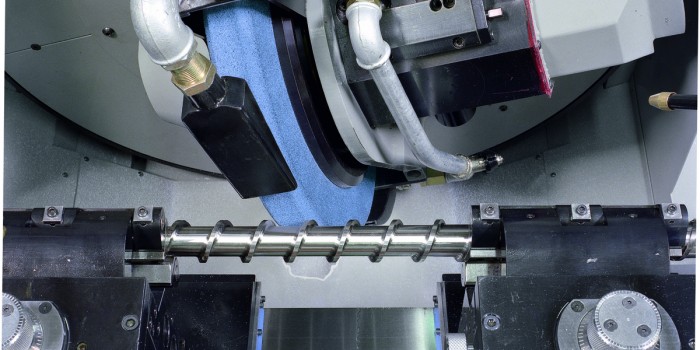

The GR 500 H screw profile grinding machine has been specifically designed for efficient high precision grinding of a wide range of screw-type profiles including worms, ball screws, rotors, hydraulic pump screws.

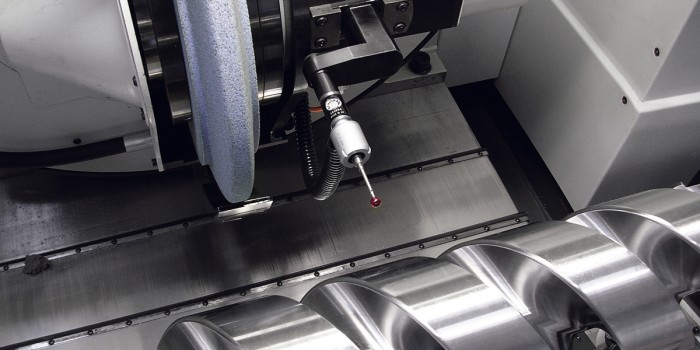

The high performance grinding spindle is generously motorized and the machine is designed with an appropriately sized coolant filtration system, allowing you to grind workpieces from solid as well as hardened steel. With a dressing unit for ceramic bonded grinding wheels and an integrated checking unit, this gear profile grinding machine is perfect for the prototyping and for the production of the smallest batches or mass production applications alike, making it a very flexible asset.

Connection to a portal loader and direct communication with an external measuring unit enhance the efficiency of your production process (close loop).

The GR 500 H comes with a specific software package for screw-type workpieces, developed and tested under real manufacturing conditions.

Advantages GR 500 H

- Dedicated version for the manufacture of rotors and screw-type workpieces

- Powerful main spindle for high stock removal rates

- Specific software packages for rotor and screw production are also available

- Specific dressing unit with two dressing wheels to dress high profiles

- Standard and special workpiece support solutions

- Automation by portal loader or robotic device

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Profile grinding of gears and long, slim and toothed components is performed discontinuously, i.e., tooth gap by tooth gap, is completed one after the…

Technical Data

Module, max.

35.0 mm

Workpiece dia., max.

400 mm

15.5 in

Workpiece length, max.

1,250 mm

49 in

| Module, max. | mm | 35.0 |

| Workpiece dia., max. | mm in | 400 15.5 |

| Workpiece length, max. | mm in | 1,250 49 |

| Workpiece weight, max. | kg lb | 250,350 551,927.5 |

| Profile depth, max. | mm in | 80 3 |

We're here for you

Do you have questions or need more detailed information? Please contact us!

To contact