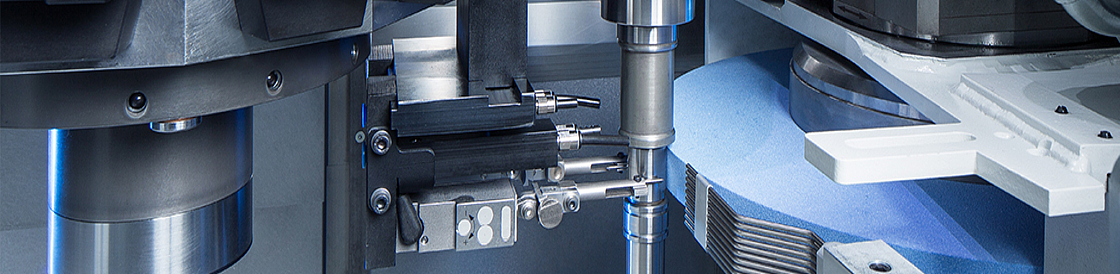

Grinding Machines for Cylindrical and Non-Round Workpieces

EMAG manufactures grinding machines for a wide range of applications. Whether its internal or external cylindrical grinding, non-round machining for parts such as cams or crankshaft grinding – EMAG provides the right technology!

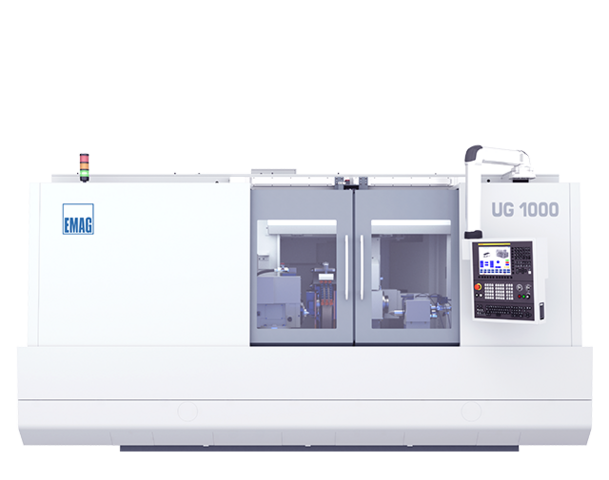

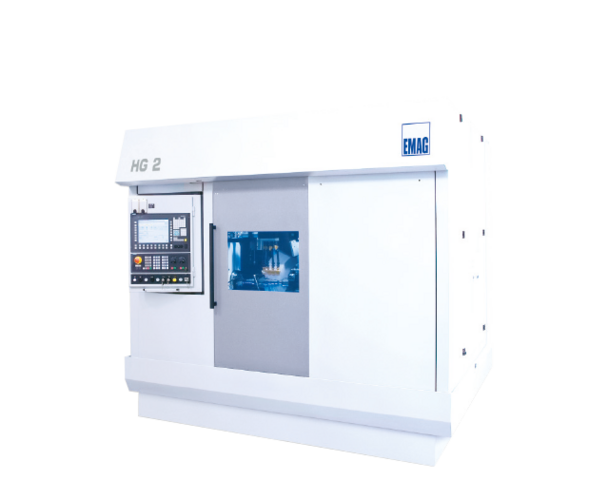

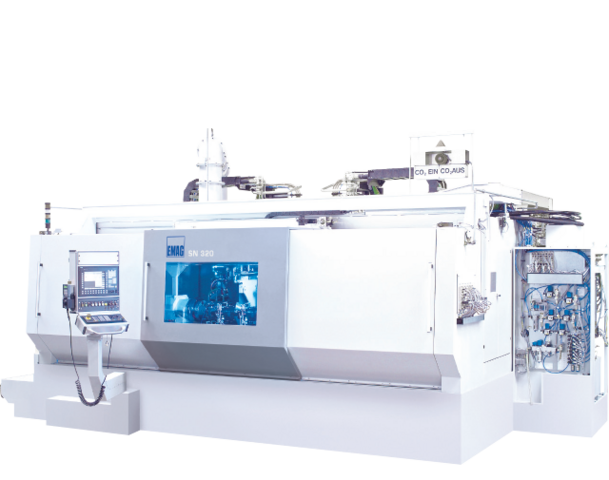

Grinding Machines from EMAG — Machine Overview

(17) machines found