Vertical Turning and Grinding Centers, Chucked Components

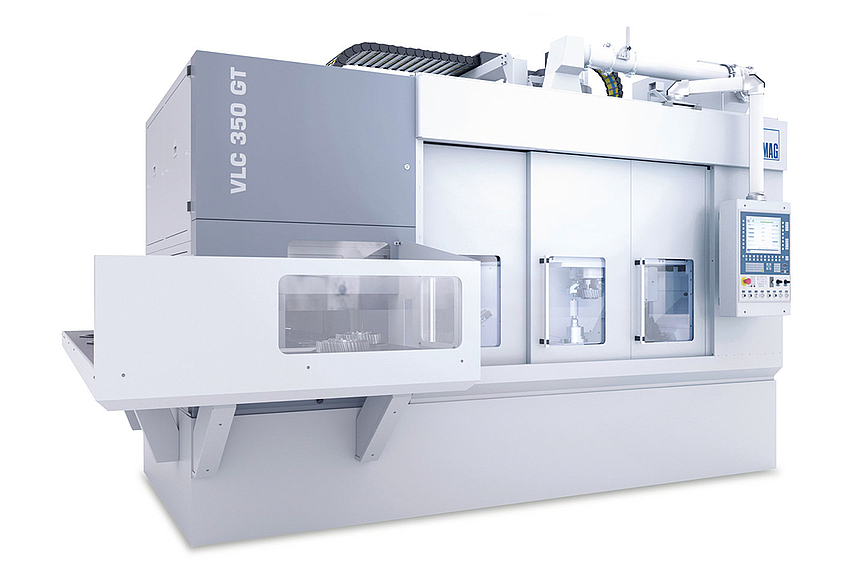

VLC 350 GT

- Workpiece dia., max.: 350 mm | 14 in

- Workpiece length, max.: 200 mm | 8 in

- Chuck dia., max.: 400 mm | 15.5 in

The VLC 350 GT Turning/Grinding Machine—Hard Turning and Grinding of Chucked Components in Transmission and Engine Production

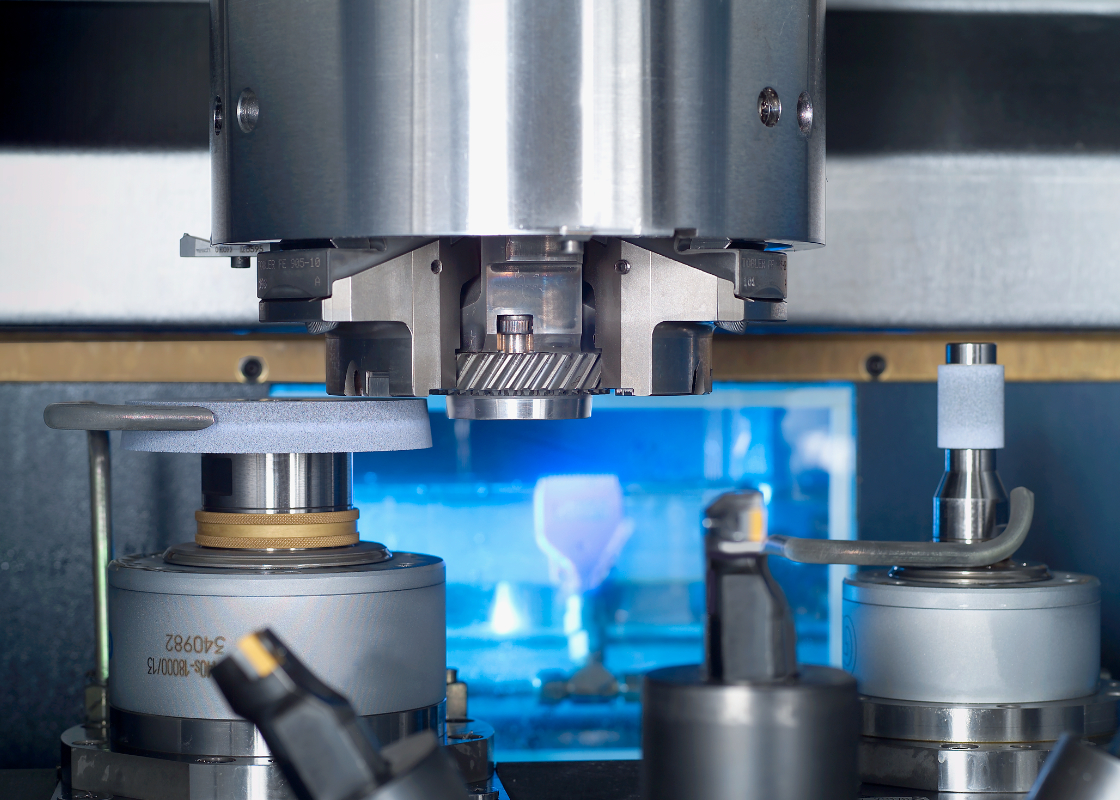

With the VLC 350 GT turning/grinding machine from EMAG, a variety of hard machining processes are performed one after the other on chucked components up to 350 mm (14 in) in diameter, in a single clamping operation.

VLC 350 GT—Turning and Grinding in One Machine

The abbreviation “GT” stands for “grinding” and “turning.” It signifies the main strengths of the VLC GT machine: The combination of grinding and turning (and additional processes) with EMAG's proven pick-up automation system allows for countless manufacturing solutions.

The VLC 350 GT turning/grinding machine is larger than the VLC 200 GT, and designed for components with a maximum diameter of 350 mm (14 in).

For the first time ever, there is the option of integrating a grinding spindle with an NC swiveling axis. This can hold, for example, a cylindrical grinding element for grinding internal boreholes.

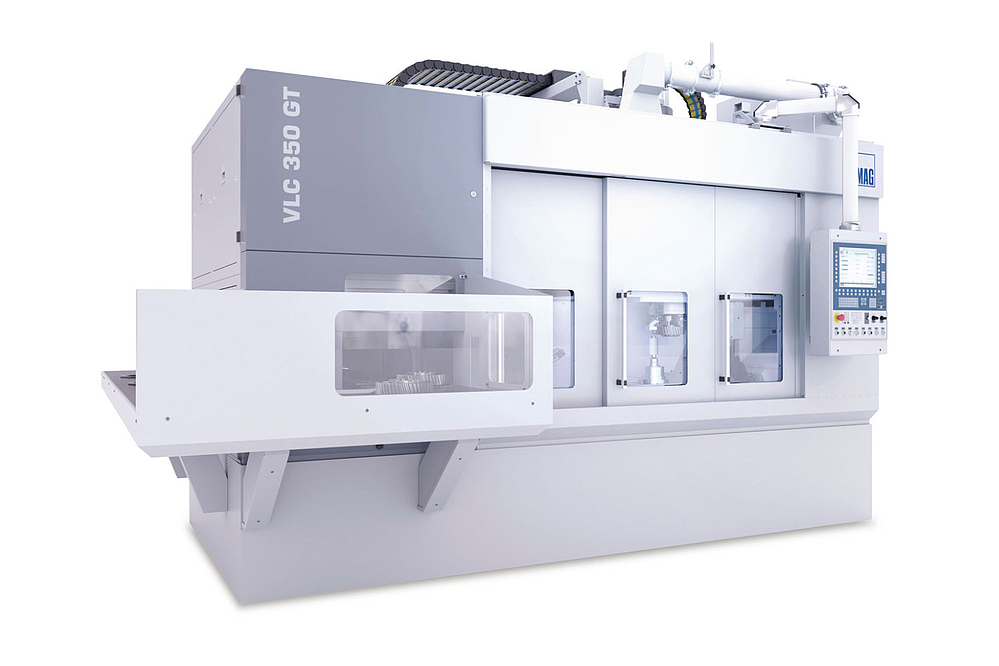

The VLC 350 GT turning/grinding machine is also perfect for small batch production. The machine has enough space in its machining area to accommodate a variety of different grinding spindles, right from the start to save time in retooling.

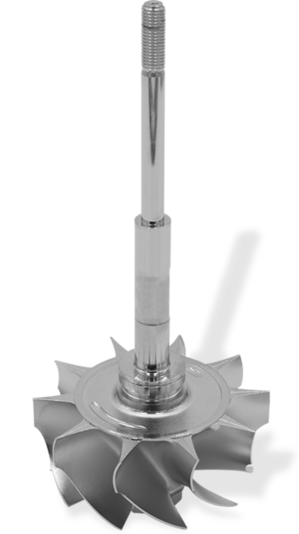

From Traditional Gears to Chucked Components with Internal Taper

The VLC 350 GT allows for the traditional hard machining of gears, from hard turning of end faces and pre-turning of the boreholes and outer synchronizing taper, through to finish grinding of those contours. The VLC 350 GT can also machine other chucked components with internal tapers. For components with internal tapers, the internal grinding spindle with NC swiveling axis pays off:

1. End Face Turning:

Loading (and subsequent unloading) is performed at high speeds with a pick-up spindle. The machining operation starts with hard turning of the end faces.

2. Contour Turning:

Depending on the component geometry, inner contours (with one or two tapers), a cylindrical borehole, and the outer synchronizing taper can be pre-turned in the second step.

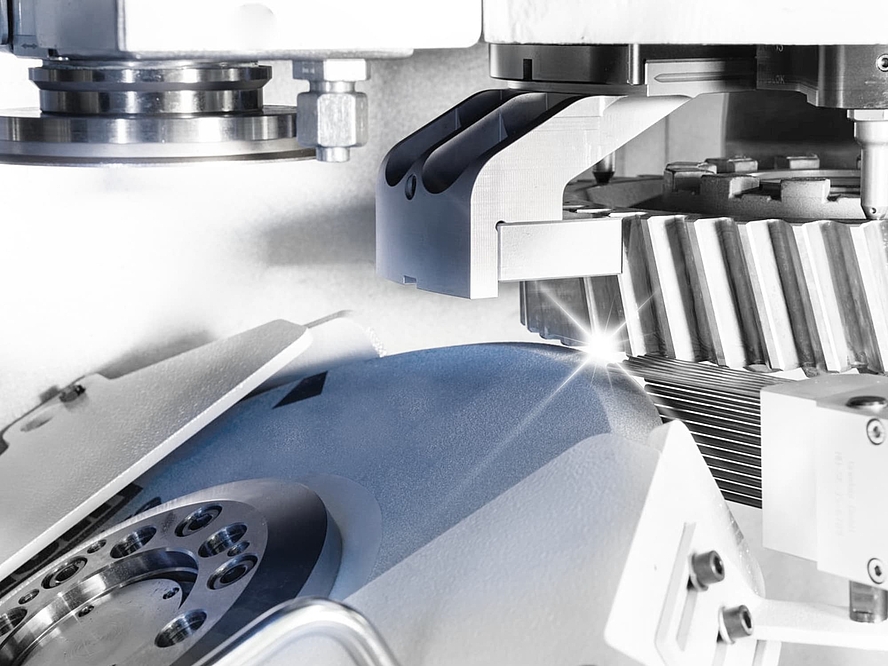

3. Grinding the Internal Contours:

The use of a cylindrical grinding element on the swiveling NC axis makes it possible to machine various internal taper angles. To do this, the grinding spindle is swivels precisely to the required angle for the specific case. Any required boreholes are also completed this way (with a zero-degree grinding angle).

4. Grinding the Outer Contours:

The final step is the grinding of the outer synchronizing taper with the external grinding spindle.

Shorter Cycle Times—Decreasing Tool Costs

The combination machining, comprises of both (hard) turning and grinding, ensures rapid processes and high machining quality. The residual machining allowance after turning is just a few millimeters. Consequently, the grinding process with aluminum oxide or CBN grinding wheels takes considerably less time. Considering the low residual machining allowance, the specification of the grinding wheel can also be geared more specifically toward final quality. An integrated measuring probe checks the diameter and length of the component after the process. In addition, a linear motor in the X-axis ensures short chip-to-chip times, because it moves the components to the machining position particularly fast.

Flexible Configuration—Many Solutions

Owing to its performance, the VLC 350 GT turning/grinding machine is recommended for medium and high-volume production. Its ease of tooling, including two large doors and accessible tools, as well as its flexibility in terms of configuration, also make it appealing for small batch sizes with frequently changing production tasks. At the same time, the machine can be loaded manually or integrated into production lines.

Advantages VLC 350 GT

- Complete machining with a single clamping operation

- Optimal cycle times due to combined processes

- Minimal grinding wheel wear—CBN technology allows for increased productivity

- 12-compartment tool turret enables all EMAG machining technologies

- New B-axis in the internal grinding spindle for machining of taper angles

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

The combination of a number of processes – such as hard turning and grinding – on a single machine, allows for the exploitation of considerable…

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process…

Technical Data

Workpiece dia., max.

350 mm

14 in

Workpiece length, max.

200 mm

8 in

Chuck dia., max.

400 mm

15.5 in

| Workpiece dia., max. |

mm

in |

350

14 |

| Workpiece length, max. |

mm

in |

200

8 |

| Chuck dia., max. |

mm

in |

400

15.5 |