01/13/2020 - Oliver Hagenlocher - Press

The New EMAG Systems: EMAG provides complete turnkey solutions from a single source

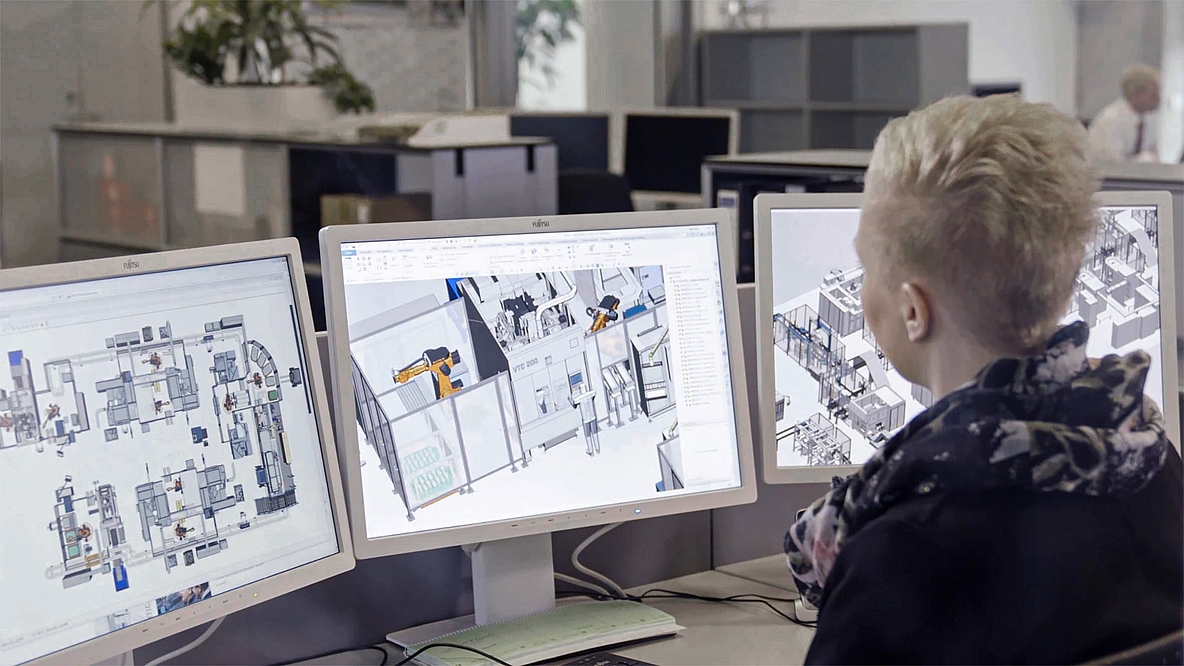

The production of comprehensive manufacturing solutions from a single source is the main requirement for many mechanical engineering production planners. Typically, a general contractor would be responsible for the development of a complex line of interlinked machines with a variety of technologies. This provides the manufacturing company with two major benefits: the overall planning is easier (of the new factory) and a production partner that guarantees a perfectly designed, flexible, manufacturing solution, even for the most complex production situation. For years, the EMAG Group has been this partner, as it is one of the few machine builders that covers the entire process chain from soft to hard machining. Now, the experts are taking the next step with the creation of EMAG Systems and combining their project engineering expertise. The new company is the perfect partner for creating turnkey solutions, and is responsible for the overall project – combining the experience and knowledge of the various EMAG branches when necessary.

Images

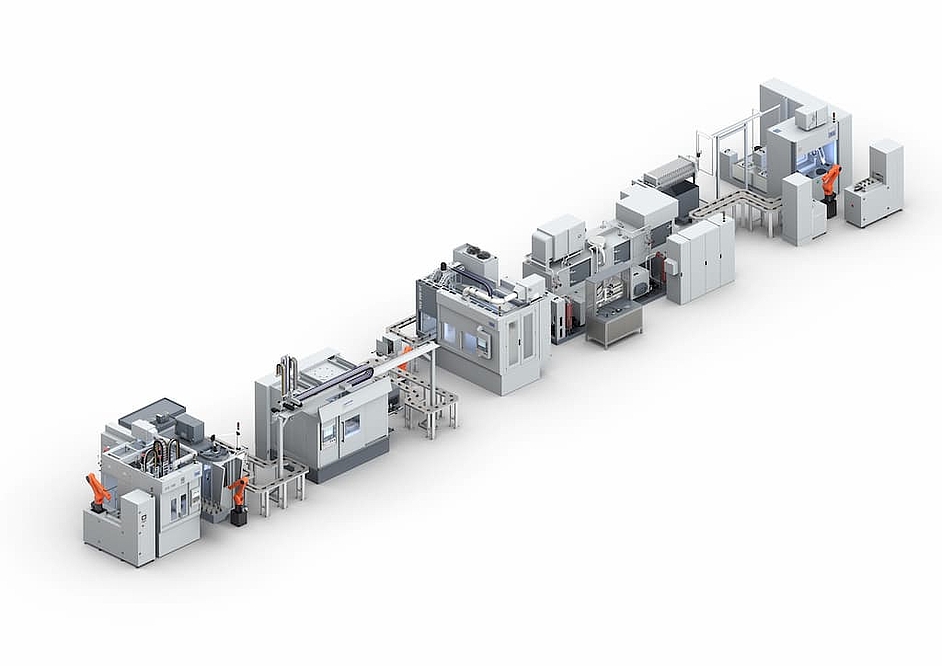

For example, e-mobility: Here, the requirement for increased quantities is currently shifting the focus to the establishment of comprehensive production systems. Ultimately, this is the only way to be able to produce complex components such as rotor shafts or differentials in a process-consistent and cost efficient manner. In the interlinked systems, for example, soft machining, hardening and hard machining take place in direct succession and numerous technologies from turning, drilling and milling to induction hardening and grinding are used. Throughout the planning of these complex systems, EMAG will work with the customer to answer a variety of production questions. For example, to understand the exact benefits and performance limitations that the user will need to achieve with their tool processes, as well as opportunities for the part to be evaluated. EMAG, with their vast expertise, processes and ability to create processes internally, will then use this information to create a customized system for the end user.

Combined System Expertise

With all of these tools at their disposal, EMAG has been enjoying growing success in the production of turnkey manufacturing solutions in recent years. The mechanical engineering company even underwent an audit by a major OEM, in which all processes and structures relating to the development of large production systems were successfully examined. The specialists regularly provide proof of their system expertise outside the automotive industry, as demonstrated by various solutions for oil production technology manufacturers. In the past, experts within the individual EMAG companies performed the corresponding project management, but now EMAG Systems is taking on this task globally. This is because EMAG believes that this area of business is increasing in importance with the demand for complete production systems growing, and the range of products and parts increasing at many supplier companies and OEMs. These changes are putting more demand on the flexibility of production systems, and more pressure on project engineers. And for these customers, EMAG Systems provides a central point of contact with experience in comprehensive turnkey production. These specialists, based in Salach, Germany, will examine each inquiry in detail, and then determine which technologies are needed for the project. With this information they will form a project team, consisting of engineers from different EMAG companies – this team will work together to form a completely customized solution for the project.

Although EMAG Systems may be new, our team is not! We have a variety of experts from within the company, who have been responsible for similar projects for EMAG in the past. With this team, customers will benefit from the experience and in-depth knowledge of all of the Group’s technologies. Within this new organization, the expertise of the employees will be combined, and the internal processes will be simplified. This allows those at EMAG Systems to focus on providing customers with a comprehensive process, while the individual EMAG companies focus on their specific technologies.

Initial Success Confirming the Path

Overall, the EMAG Systems experts see their market opportunities as very positive. After all, in the automotive industry, for example, many supplier companies must position themselves much more broadly and establish independent production solutions for a larger number of different drive technologies - from the classic "combustion engine" and hybrid solutions to completely electric. In this industry, the demand for EMAG’s resource planning expertise is growing quicklyA second factor in the success of EMAG Systems is Industry 4.0. After all, Smart Factories that increase the productivity of a location, or improve process reliability are impossible without comprehensive, linked systems. This is where EMAG Systems and its project engineers play a critical role. A variety of current projects shows that this full scope approach is working in the market, especially in e-mobility. For example, EMAG is currently developing two production systems for machining a rotor shaft for European customers. With the introduction of EMAG Systems, EMAG plans to present their proven project engineering expertise to the market in a selective manner, while continuing to grow over the next couple of years, and continuing to advance the technological development of production systems.

Downloads

Contact

Oliver Hagenlocher

Area

Press and Communication