06/02/2021 - Oliver Hagenlocher - Press

Manufacturing Solution for Trucks: EMAG presents a Compact Manufacturing Solution for Truck Wheel Hubs

The race for future market shares is proof that e-mobility is not only shaking up the passenger car sector, but has long since taken hold of the truck sector as well. Established manufacturers are being joined in the market by a number of newcomers and start-ups. The first major contracts for the ‘new kids on the block’ are a sign that significant changes are taking place, and there is currently no telling who will succeed in the market. What is clear, however, is that the manufacturing of commercial vehicles is becoming more diversified and complex. Due to this, manufacturers and suppliers rely, more than anything, on flexible manufacturing systems to meet these demands.

EMAG identified this need and, in response, developed a compact manufacturing solution for truck wheel hubs – although, it’s not necessarily just for electric trucks.

Images

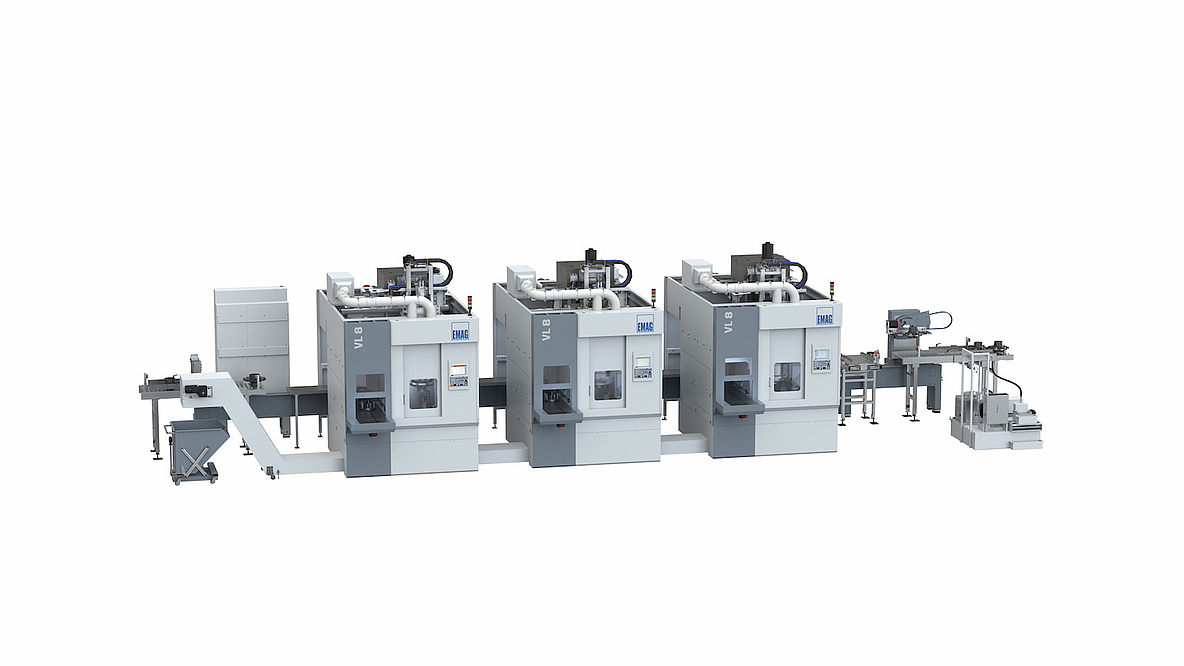

In planning the manufacturing line for truck wheel hubs, the designers based their solution on the compact designs that EMAG is known. This is a result of the high degree of automation and the vertical structure of the vertical pick-up machines used. In combination with the TrackMotion automation system, which effectively runs through the machines, this allows the machines to be positioned very closely together. The final result is compact manufacturing cells, which can easily be duplicated or multiplied depending on the output capacity required.

Perfect combination of pick-up turning center and TrackMotion

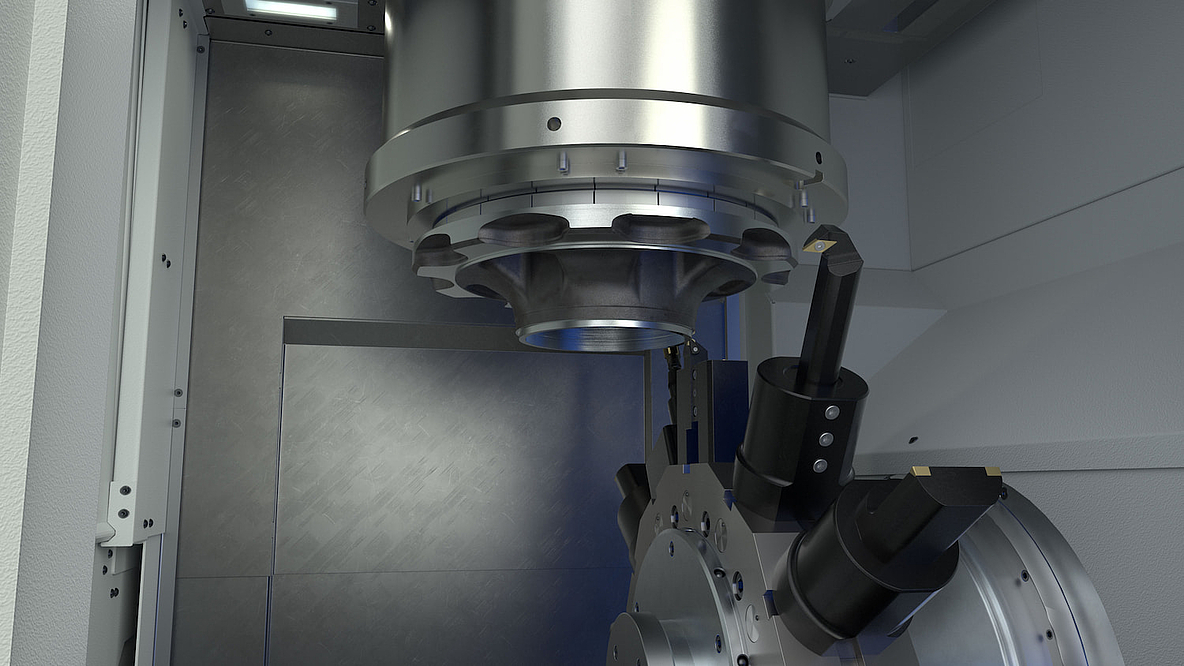

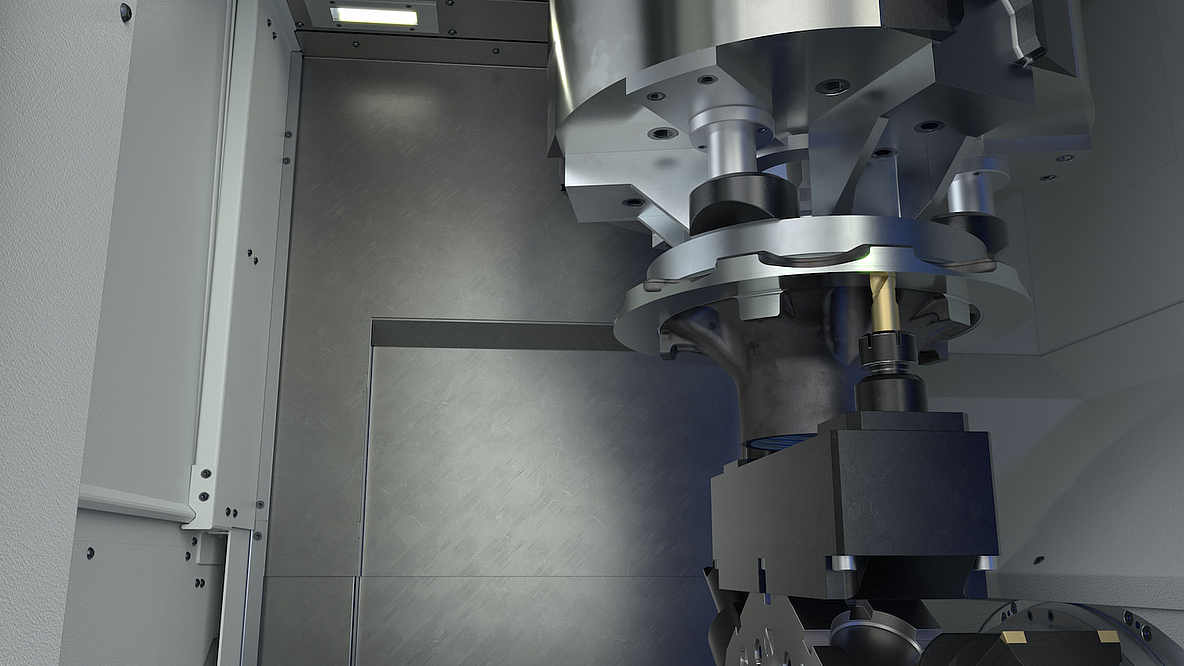

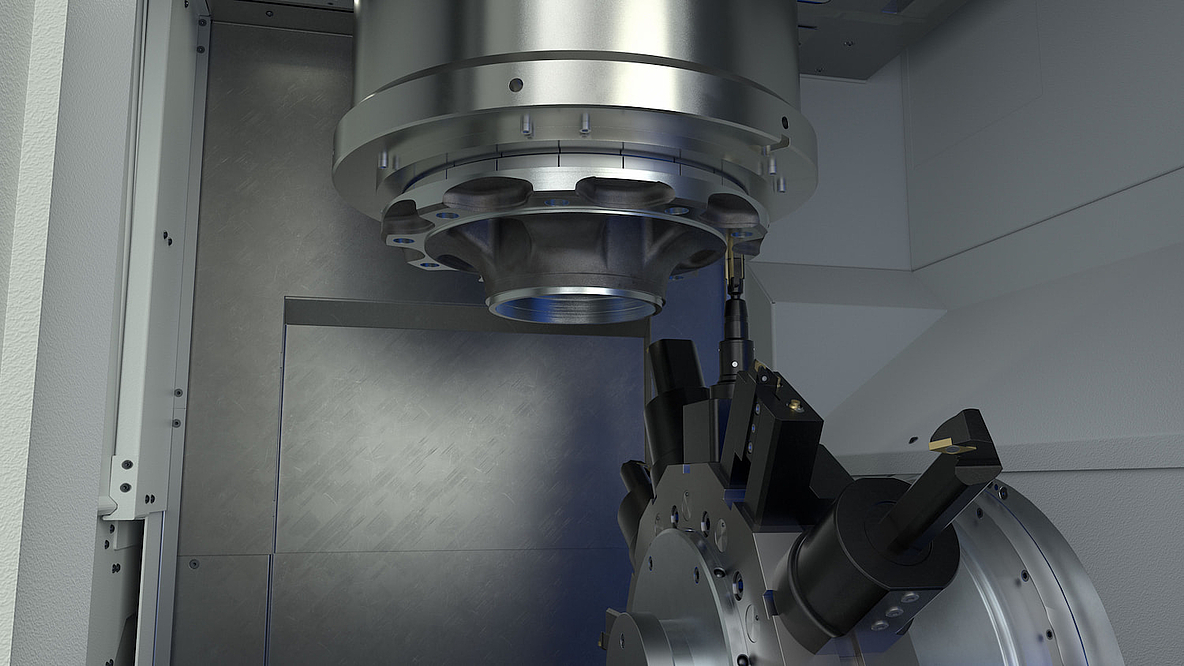

A closer look at the line structure reveals how EMAG’s highly flexible production solutions work: truck wheel hubs are generally machined in three clamping operations, i.e. using three spindles or machines. In OP 10, the outer and inner contours of the wheel hub are turned. The side is rough- and finish-machined in a single clamping operation. After the wheel hub has been rotated by the TrackMotion system, the second side is machined in OP 20. With a driven tool turret, the holes for the bolts can be drilled here. Afterwards, the component is finish-machined and the grooves are milled in OP 30. Here another driven tool turret is used to cut the threads in the holes. These machines are interlinked by the proprietary EMAG TrackMotion system. In this automation system, a gripper unit moves on a linear track. It transports the workpiece from the blank infeed to the individual machines and process steps, and then to the finished-part outfeed. The benefits: On the one hand, the user can modify the overall system at any time. For example, it is possible to ‘switch out’ a machine from the process if a workpiece does not require all the operation steps, or if the process sequence for a particular machine is to be modified. This might be necessary for different wheel hub types, due to differences in the clamping sequences. Time-consuming retooling with different clamping devices is reduced to a minimum. On the other hand, EMAG can integrate several machines into the chain to perform the same operation in parallel. In this case, the TrackMotion system distributes the workpieces to the machine that is free at the moment. Because of this, tooling work on a machine no longer means downtime for the entire production line.

VL 8 pick-up turning center

The VL 8 used has a chuck diameter of 500 millimeters, this allows the pick-up spindle to handle workpieces with diameters as large as 400 millimeters. With a drive power of up to 71.7 kW and a torque of 1,102 Nm (at 40% duty cycle), the high-performanceoption of the main spindle has enough cutting capacity to machine the wheel hubs at high speed. EMAG’s own tool turret is used here. It can be equipped with 12 turning tools or alternatively as a driven tool turret with driven drilling and milling tools. The machine's base is made from Mineralit polymer concrete. It guarantees low-vibration processes, ensuring long tool lifetimes and very high machining quality.

EDNA – Industry 4.0 platform

The keyword ‘Industry 4.0’ plays an important role at EMAG. With EDNA, the ‘EMAG DNA’, the company has developed a modular software ecosystem. Not only does it improve the configuration and operation of individual machines and entire production systems, its data-driven applications also bring transparency to the overall production process andform the basis for a smart factory.

The ‘EDNA Healthcheck’ for machine maintenance makes it possible, for example, to detect wear of the axis drives at a very early stage and, with little effort, schedule necessary maintenance tasks in advance.

Flexible, fast, precise, and highly productive at the same time –EMAG has achieved an excellent market position in the area of manufacturing lines over the last few decades. Of course, these characteristics also apply to the line for truck wheel hubs presented here. These benefits are sure to contribute to EMAG becoming more established in the commercial vehicles sector too.

Contact

Oliver Hagenlocher

Area

Press and Communication