Archive

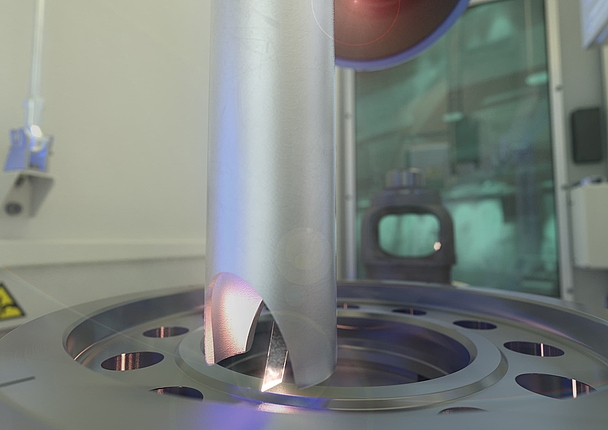

11/04/2020 - Oliver Hagenlocher - Press

LC 4-2 Laser Cleaning Machine: Focused on Fast Cleaning Processes and Optimizing Component Surface QualityThe need for industrial cleaning processes is not uncommon – many parts are contaminated with substances including oil and adhesives, or have undesired layers of oxide, rust, phosphate, or paint that needs to be removed before additional machining…

10/05/2020 - Oliver Hagenlocher - Press

Red Dot Award for EMAG: AI solution EDNA perfects networking of industrial productionThe factories of the future are connected—in every respect: Machines communicate with each other regarding errors or required maintenance, while providing essential information to production planners that can control the machines from one central…

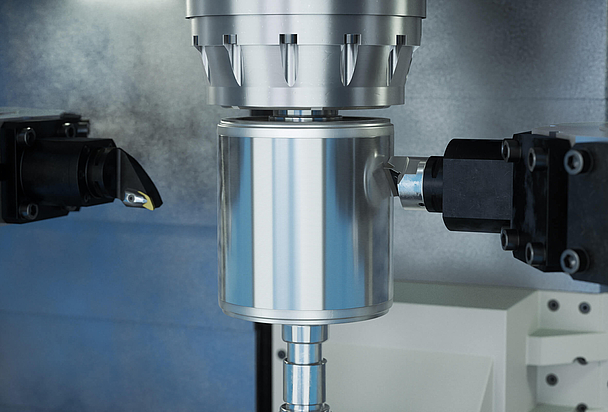

09/30/2020 - Oliver Hagenlocher - Press

Using scroll-free turning to optimize the production of rotor shaftsThe automotive industry is in transformation and production planners are placing increasing importance not only on new components, but also on new manufacturing methods. After all, the increased demand for electric vehicles is also leading to higher…

09/14/2020 - Oliver Hagenlocher - Press

The CI machine from EMAG ECM: A Highly Effective Solution for Deburring Complex ComponentsAutonomous steering and brake systems, hydro-pneumatic chassis, or radically improved gas mileage – these buzzwords represent a technological change that is triggering a domino effect in the automotive and other industries. An increasing number of…

09/07/2020 - EMAG Systems GmbH - Press

VLC 200 GT from EMAG: Combining technologies to machine state-of-the-art transmission componentsIt is no secret that e-mobility is a growing market. A current study by the consulting firm Strategy Analytics, predicts the production output of “electric vehicles” will increase to 25% of the global market by 2025. It should be noted that the study…

09/01/2020 - Oliver Hagenlocher - Press

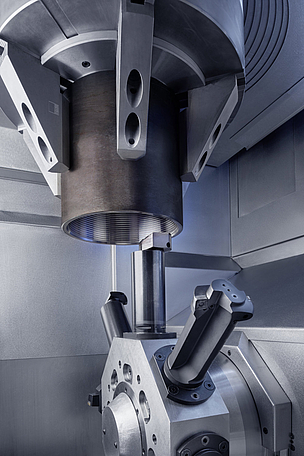

VMC 450-5 MT Turning/Milling Center – Five Axes for Dramatically Shorter Machining Processes in the Production of Large PartsLarge components and complex geometries—in heavy machining, this combination is far from rare and is always synonymous with a high expenditure of time and rising costs. A primary reason for this is that the variety of machining processes required,…

08/24/2020 - Oliver Hagenlocher - Press

HLC 150 H by EMAG KOEPFER: All-round gear-cutting solution for more flexibility and lower costMore than ever, planners in the automotive industry are faced with the crucial challenge of flexibility in production technology. Manufacturers continually need to cope with modified ranges of components. For instance, the geometry can change very…

08/17/2020 - Press

Lightweight Design for Commercial Vehicles: EMAG LaserTec is developing a holistic production solution for large truck differentialsWhen the catch phrase “lightweight design” is used for the automobile production, it typically refers to passenger cars, rarely commercial vehicles. However, there is an enormous amount of potential for weight reduction and cost savings when…

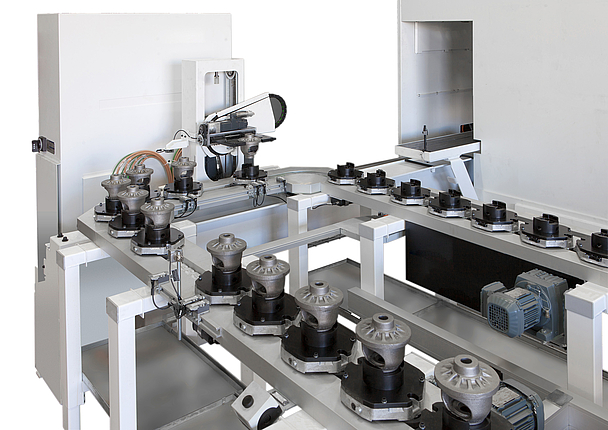

08/10/2020 - Press

Production system by EMAG: High-performance solutions for differential casesThe worldwide production of motor vehicles is set to rise by about two percent every year until 2030, according to the estimates of a new McKinsey study. An excellent example of how to handle these rising production volumes despite stringent quality…

07/16/2020 - Oliver Hagenlocher - Press

VLC 350 GT from EMAG: The perfect solution for the future of transmission and engine productions chucked partsWhat will the cars on the street look like in the future? A new study by the Boston Consulting Group forecasts a mix of gasoline and diesel engines (48 percent), hybrid vehicles (33 percent) and completely electric (19 percent). For OEM’s and supply…

06/15/2020 - Oliver Hagenlocher - Press

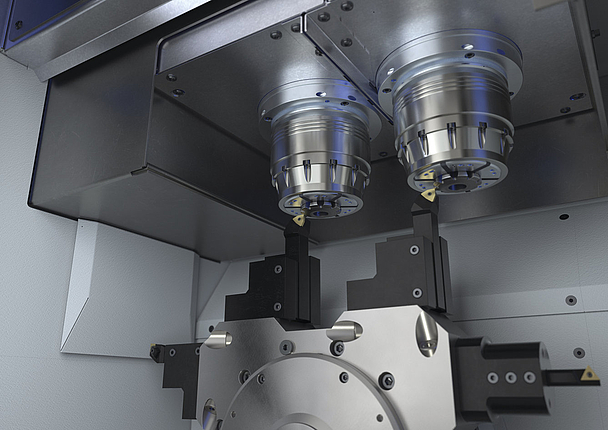

VL 1 TWIN from EMAG: Drastically Lower Unit Cost for Bevel GearsBevel gears found in passenger vehicles are mass-produced. Supply companies produce these gears, essential for differentials, by the million—and it’s no wonder, since there are four of these in every differential. The number of all-wheel-drive…

06/09/2020 - Press

EMAG Announces Expansion with the Opening of EMAG Charlotte!Beginning June 1, 2020, EMAG will be expanding its operation in the United States by opening an additional office, EMAG Charlotte, in Charlotte, NC. With this addition, current and prospective customers located in the southeastern portion of the…

05/14/2020 - Oliver Hagenlocher - Press

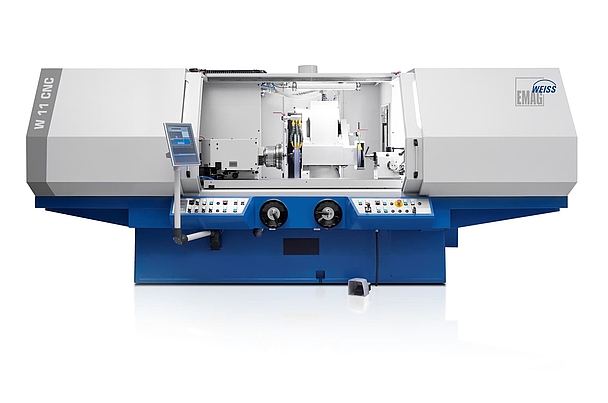

W 11 CNC from EMAG Weiss—Manual CNC-Supported External and Internal Cylindrical GrinderThe EMAG Group is breaking new ground with the W 11 CNC cylindrical grinder from EMAG Weiss. The company from Salach, near Stuttgart, Germany, is primarily known for its turning and grinding machines intended for high-volume production. With its W 11…

02/27/2020 - Oliver Hagenlocher - Press

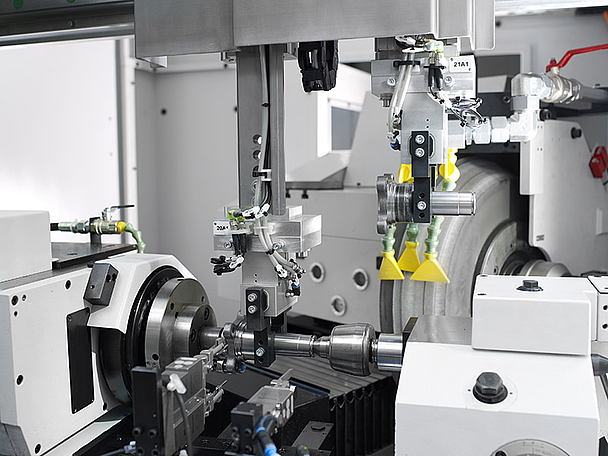

EMAG Oilfield Technology: The World Premiere of EMAG’s In-Process Non-Contact Thread Measuring SystemAccording to the 2018 energy study of the German Federal Institute for Geosciences and Natural Resources (BGR), with a share of 30.5% of the world’s primary energy consumption, oil remains the most important source of energy.

However, global trade…

02/24/2020 - Oliver Hagenlocher - Press

EMAG Receives “Outstanding Supplier” Award from SisamexThe EMAG Group and Sisamex, a member of the Mexican Quimmco Group, have been production partners for over 20-years. At its plants in Monterrey, Sisamex produces a large variety of workpieces for trucks, agricultural and utility vehicles for many…

01/15/2020 - Oliver Hagenlocher - Press

EMAG Acquires CNC-Technik Weiss GmbH Headquartered in Neckartailfingen, GermanyThe EMAG Group is expanding its technology range in the field of grinding with cylindrical grinding technology from WEISS. “We are extending our range of products in the area of high-output and high-precision cylindrical grinders with grinding…

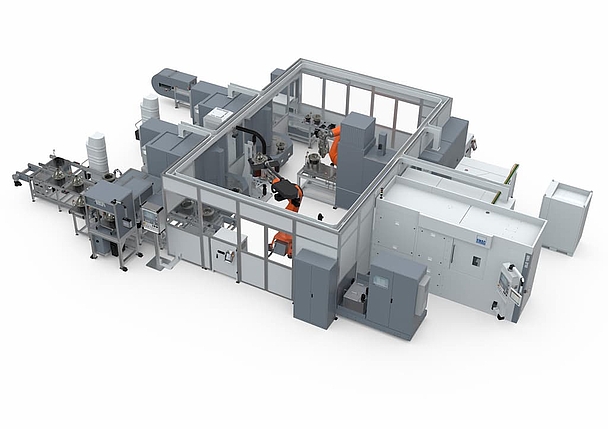

01/13/2020 - Oliver Hagenlocher - Press

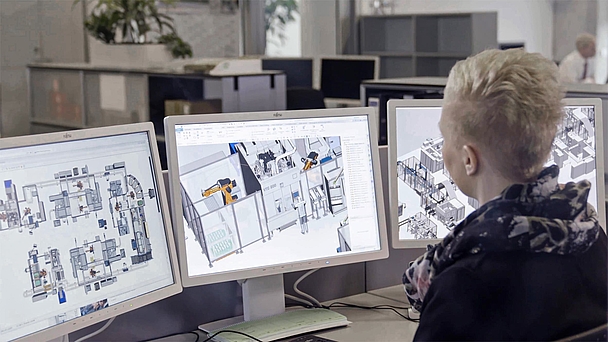

The New EMAG Systems: EMAG provides complete turnkey solutions from a single sourceThe production of comprehensive manufacturing solutions from a single source is the main requirement for many mechanical engineering production planners. Typically, a general contractor would be responsible for the development of a complex line of…