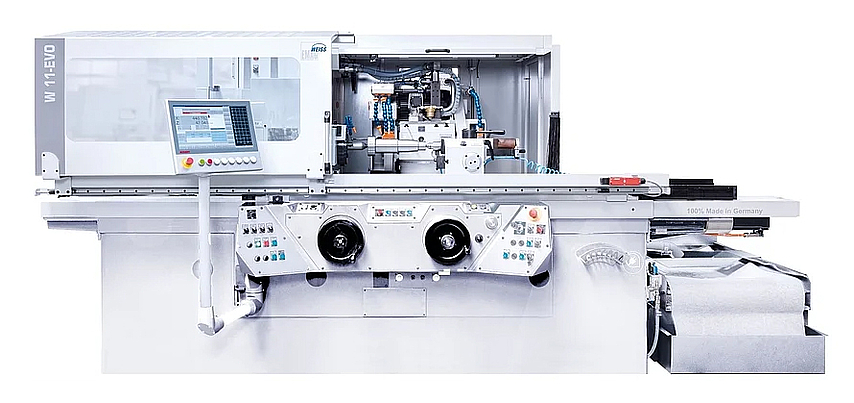

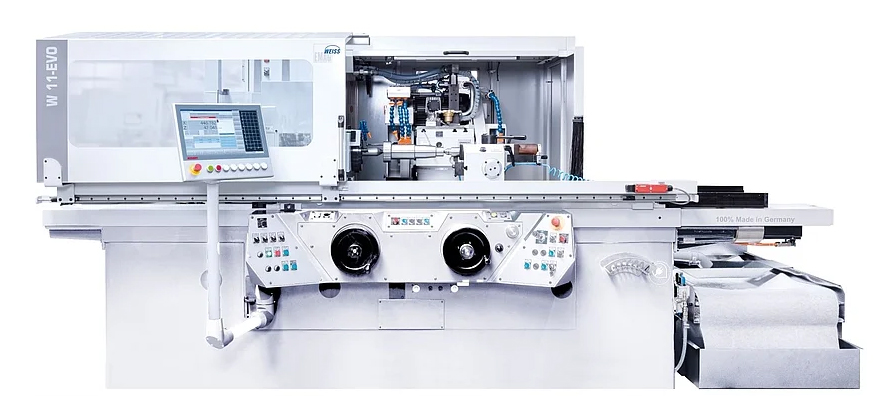

Universal Cylindrical Grinding Machines

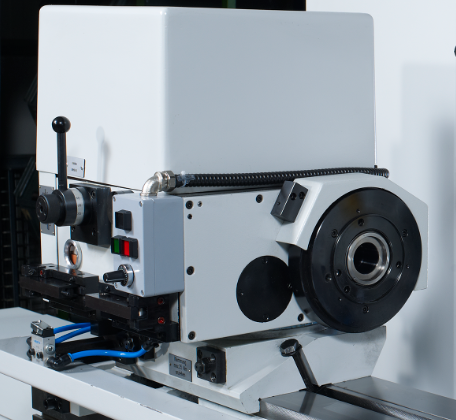

W 11-EVO

- Grinding length, max.: 650 / 1,500 mm | 25.5 / 59 in

- Center height: 180 / 200 mm | 7 / 8 in

- Grinding Ø external: 0 / 390 mm | 0 / 15.5 in

Conventional cylindrical grinders: W 11-EVO

The basis of the EMAG Weiss W 11 machines is the established KARSTENS cylindrical grinder concept. KARSTENS has produced more than 4,500 units of the K 11 machines. Even today, around 1,000 machines are still in use around the globe. In 1994, CNC-TECHNIK WEISS GMBH started to overhaul and service KARSTENS K 11 machines.

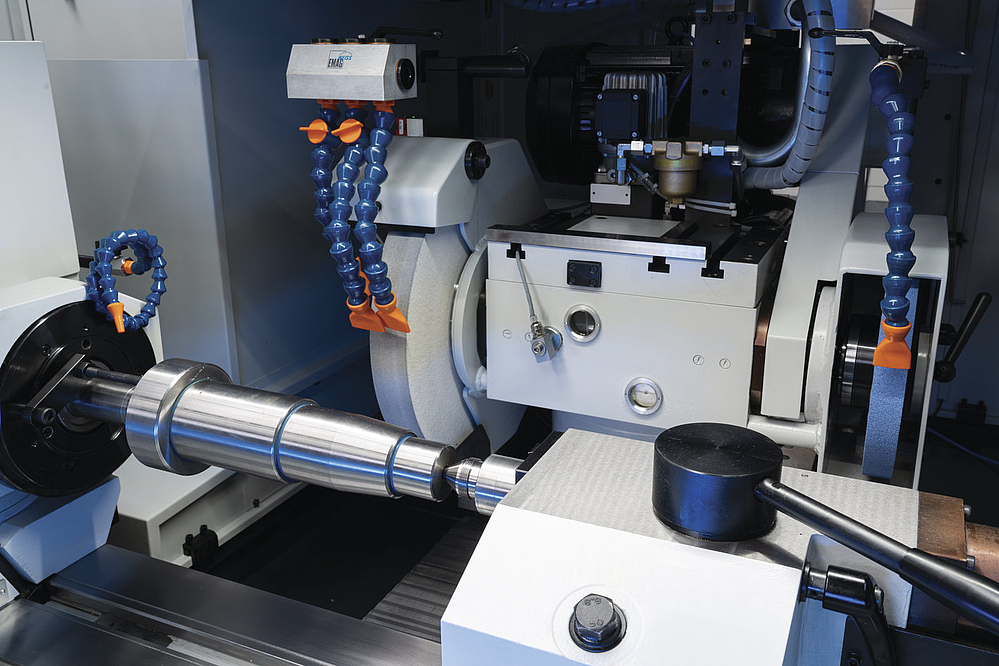

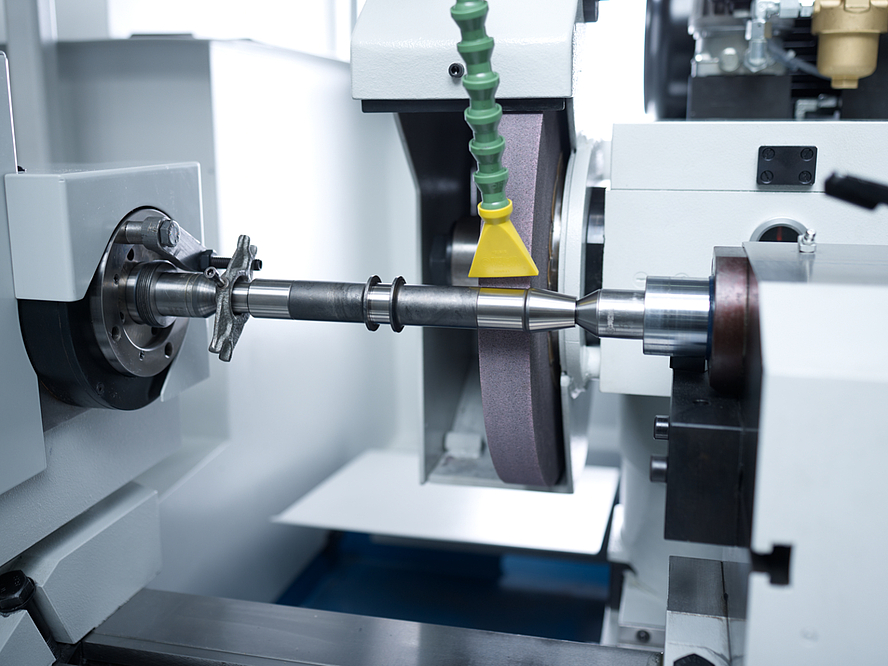

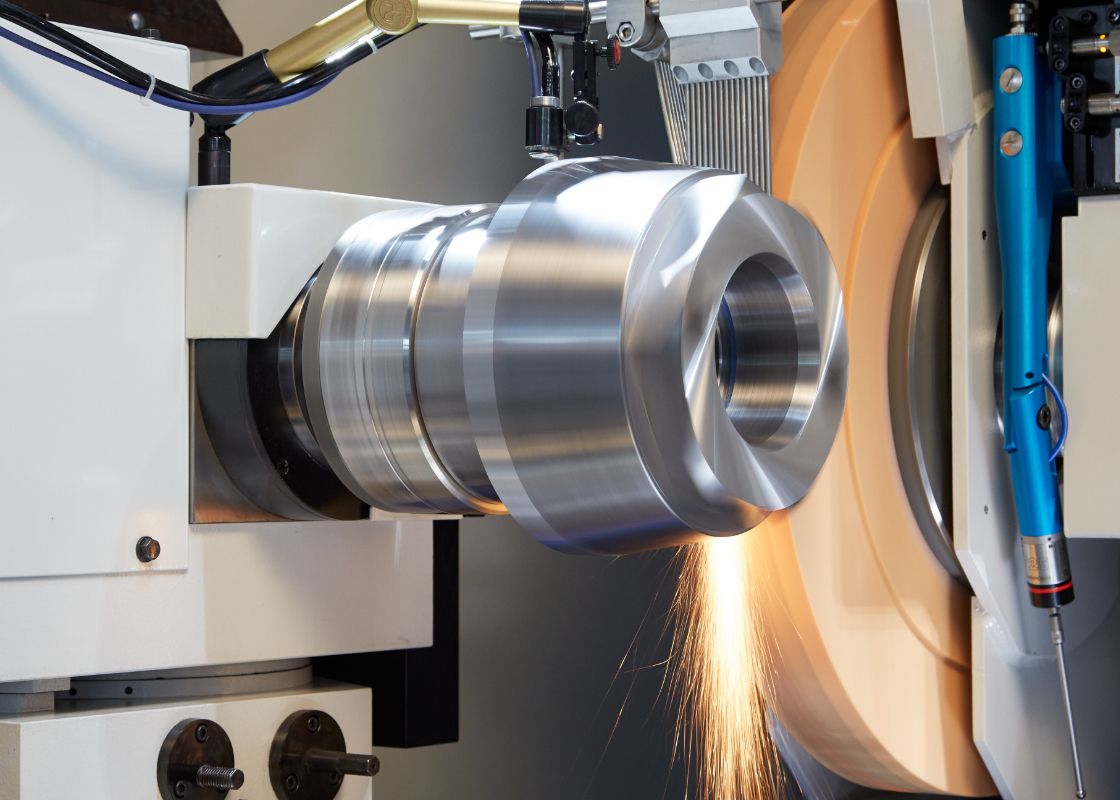

Conventional external-internal face cylindrical grinding machine – Perfect for single parts, prototypes, and small batches

Since 2010, we have been offering the W 11 cylindrical grinder to our customers as a new or retrofit machine. All of its technology has continuously been developed and optimized over the years, and all components are compliant with the current machinery directives.

Thanks to the continuous technical development, it is possible to acquire the W 11 cylindrical grinder as a new machine with up-to-date technology that can be customized.

Applications of the W 11-EVO cylindrical grinder

- Single part production

- Prototype production

- Small batches with small diameters

- Pair grinding

- Sample production

- Training and maintenance

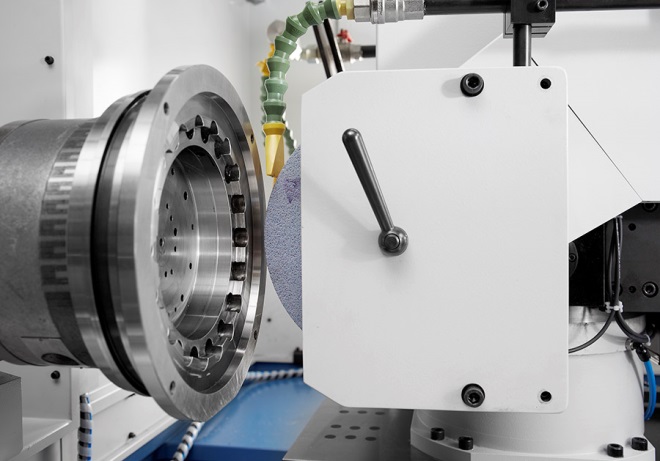

W 11-EVO: The new grinder generation

We offer the W 11 in a new, modern design: no hydraulics, axis drives with servo motors and screw spindle drive, technology entry of the grinding parameters via touchscreen, automatic parallel dressing with compensation, automatic axis release. All of this using the simple and time-tested control concept of the classic W 11!

Advantages W 11-EVO

- Extremely flexible

- Very easy tooling

- Simple and user-friendly

- Quick-action clamps on the assemblies for re-tooling

- Very precise infeed and dimensional accuracy within 0.001 mm

- Good access for the operator

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Universal cylindrical grinding generally refers to the cylindrical grinding process applied to the outside or inside diameter of a part. For external…

Technical Data

Grinding length, max.

650 / 1,500 mm

25.5 / 59 in

Center height

180 / 200 mm

7 / 8 in

Grinding Ø external

0 / 390 mm

0 / 15.5 in

| Grinding length, max. |

mm

in |

650

/ 1,500

25.5 / 59 |

| Center height |

mm

in |

180

/ 200

7 / 8 |

| Grinding Ø external |

mm

in |

0

/ 390

0 / 15.5 |

| max. workpiece weight floating MK4 |

kg

lb |

100

220.5 |