Customized – External Grinding – HG

HG 2

- Workpiece dia., max.: 200 mm | 8 in

- Workpiece length, max.: 400 mm | 15.5 in

- X-axis travel: 360 mm | 14 in

Cylindrical Grinding with the Cylindrical Grinder HG 2

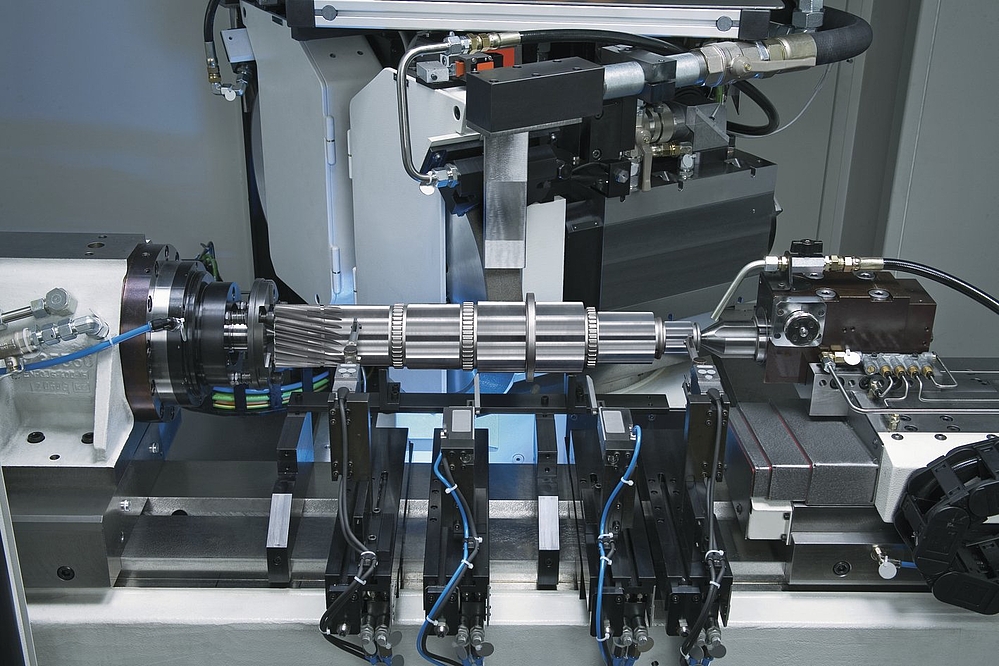

Finding the ideal balance between flexibility and productivity is essential when designing machines for cylindrical grinding, and the HG 2 cylindrical grinder is perfect to meet these demands. From batch sizes of 50 shafts, to three-shift operations, every application of the cylindrical grinding technology for shafts is covered. The HG 2 was designed to provide the ideal manufacturing solution for cylindrical grinding of shafts at the best possible price by providing a high degree of standardization and a modular machine design. The HG 2 with cylindrical grinding technology is available as either a manually loaded or an automatically loaded machine that uses a gantry.

The automated version of this machine can be used for the cylindrical grinding of workpieces between 150 and 400 mm (2 and 16 in) and the manual version can be used for up to 600 mm (24 in) in length. The following services are offered in conjunction with the machine: process design, setting up the cylindrical grinding process, commissioning and assistance during production.

HG 2 – the Efficient Solution for the Cylindrical Grinding of Shafts

For ground components, quality requirements continue to increase and for cylindrical grinding process, integrity is essential.

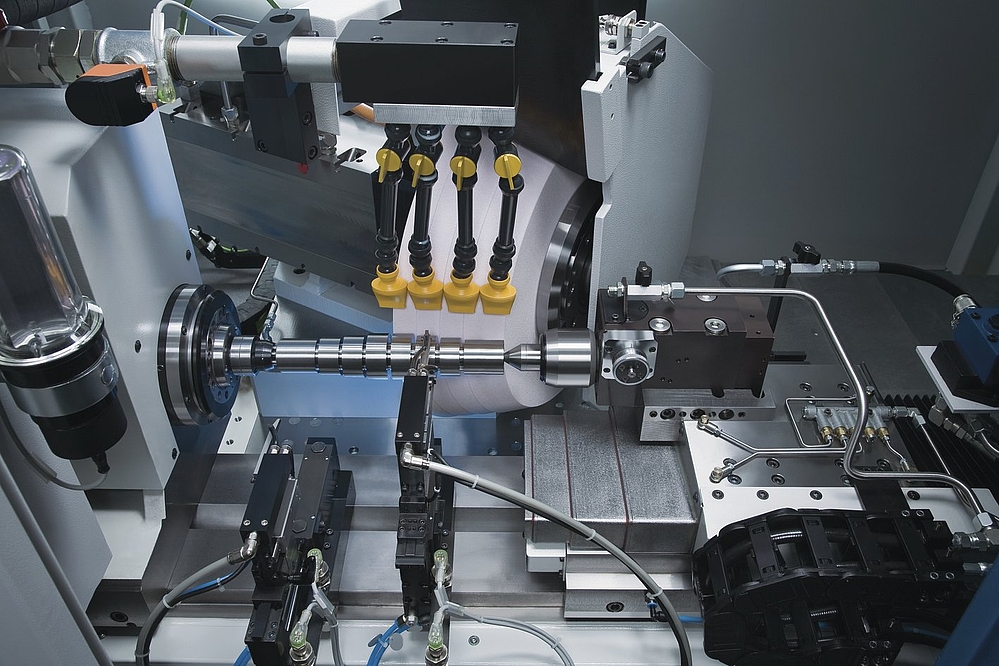

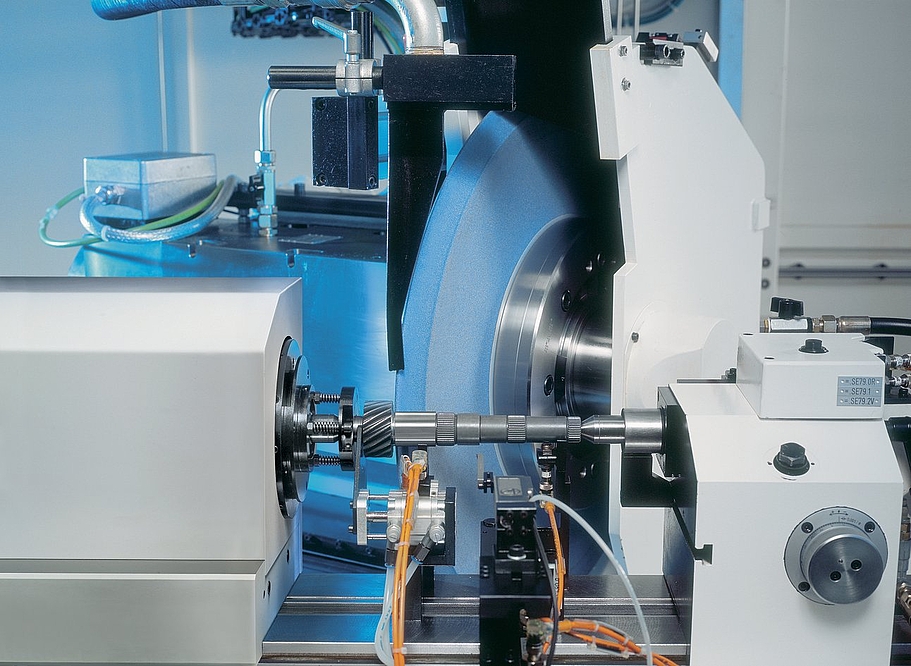

The EMAG HG 2 horizontal cylindrical grinder considers all requirements that need to be met with the cylindrical grinding process. The base of the HG 2 cylindrical grinder is made out of thermostable cast iron, this base carries the compound slide which is high static and offer dynamic rigidity. The sturdy compound table design reduces the overall machine footprint and saves on expensive floor space. It also makes the exchange of grinding wheels easier. To guarantee the highest precision, the HG 2 is equipped with precision ball screws and an absolute measuring system in the X- and Z-axis (glass scales). The machine is separated from its automation equipment to ensure that vibrations have no adverse influence on the cylindrical grinding process. NC tailstock and integrated automation ensure the cylindrical grinding machine is flexible enough to accommodate a wide variety of workpieces – this makes it possible to machine different shafts and workpiece variants on a single cylindrical grinder using cylindrical grinding technology. Anti-friction bearing-supported guideways in all linear axes allow for the smallest infeeds with excellent continuity in all movements.

The stick-slip free, well-dampened infeeds result in outstanding contour accuracy and exceptional surfaces finishes in the application of the cylindrical grinding technology.

Advantages HG 2

- Large doors increase accessibility, reducing the distance between operator and workpiece

- An operator-friendly workpiece error correction system automatically rectifies dimensional errors

- Short idle times lead to high productivity levels

- An NC tailstock with large stroke makes for easy resetting

- Absolute measuring systems (linear glass scales) in all axes ensure machining accuracy

- High-precision, sturdy linear roller guiderails in all axes guarantee the longevity of the machine

- Operator and setter menus simplify handling

- An in-process gauging control checks O/Ds and the longitudinal position on shoulders

- A contact and crash recognition and wheel balancing system monitors the grinding process

- A high-powered wheel drive shortens machining times

Technical Data

Workpiece dia., max.

200 mm

8 in

Workpiece length, max.

400 mm

15.5 in

X-axis travel

360 mm

14 in

| Workpiece dia., max. |

mm

in |

200

8 |

| Workpiece length, max. |

mm

in |

400

15.5 |