Grinding machines for gear cutting tools

GS 400

- Module range: 0.5 - 15.0

- Workpiece dia., max.: 400 mm | 15.5 in

- Workpiece length, max.: 90 mm | 3.5 in

Tool Resharpening Machine GS 400

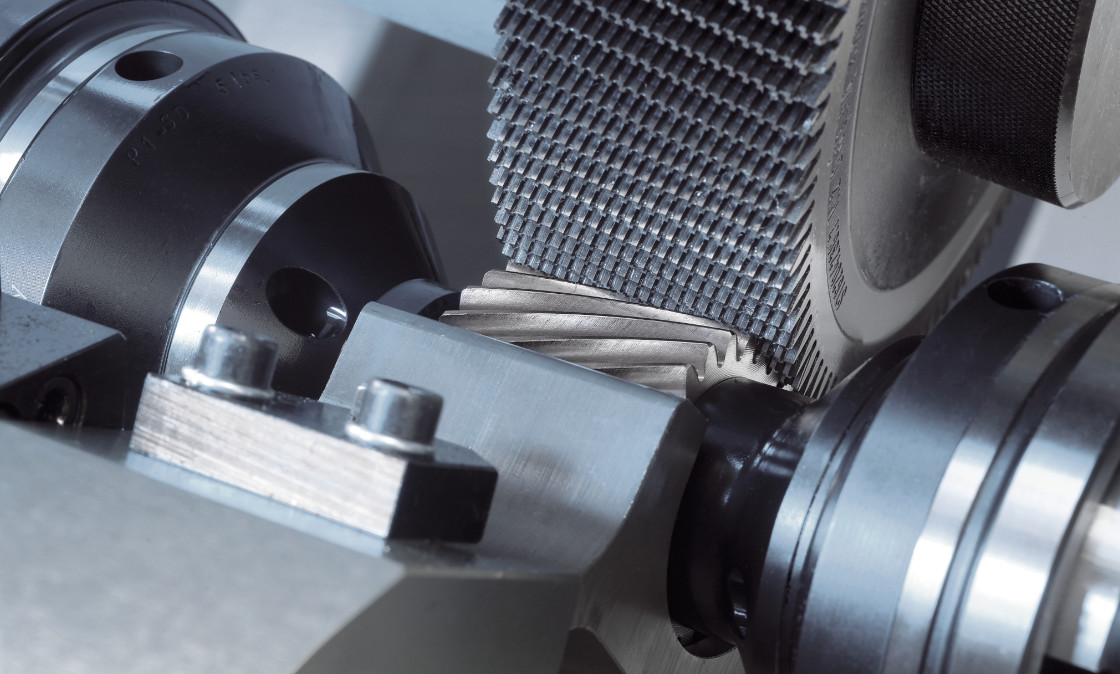

The GS 400 Tool Resharpening Machine is designed to sharpen shaving cutters and to grind master gears using the generation method.

GS 400 - Top Efficiency and Versatility

Designed to sharpen shaving cutters and to grind master gears using the generation method, the GS 400 tool resharpening machine is the fourth generation of its kind and sets new standards in terms of precision, reliability and user-friendliness.

EMAG SU interpolation software calculates the profile to be grounded and coordinates the linear movement of the transverse slide with the rotary movement of the work spindle. The resulting roll motion is steplessly adjustable in terms of the roll diameter, and indexing blocks are no longer required.

Roll motion and index movement are now numerically controlled and both generated by the same motor. All movements are actuated by linear and rotary digital drives. An integrated measuring unit automatically checks the quality of the first tooth ground without having to unclamp the workpiece and waste precious time.

The GS 400 tool resharpening machine is available with an axis X11 CNC. This new axis makes it possible to grind larger tooth widths whilst enhancing the quality of the finish. Moreover, machine set up is also quicker. Why set yourself limits? We look forward to illustrating you the advantages of the new GS 400.

Advantages GS 400

- Minimum set-up times thanks to the HMI

- Reduction of runout errors

- Easy and fast workpiece change with quick-change mechanism

- Integrated checking unit

- Grinding of shaving cutters

- Grinding of master gears

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Gear shaving takes place before the hardening process and is a cost-effective process. It results in low-noise gear surfaces - a major benefit that…

Technical Data

Module range

0.5 - 15.0

Workpiece dia., max.

400 mm

15.5 in

Workpiece length, max.

90 mm

3.5 in

| Module range | 0.5 - 15.0 | |

| Workpiece dia., max. |

mm

in |

400

15.5 |

| Workpiece length, max. |

mm

in |

90

3.5 |

| Workpiece diameter, min. |

mm

in |

60

2.5 |

| Face width, max. |

mm

in |

70

3 |

| No. of teeth | unlimited | |

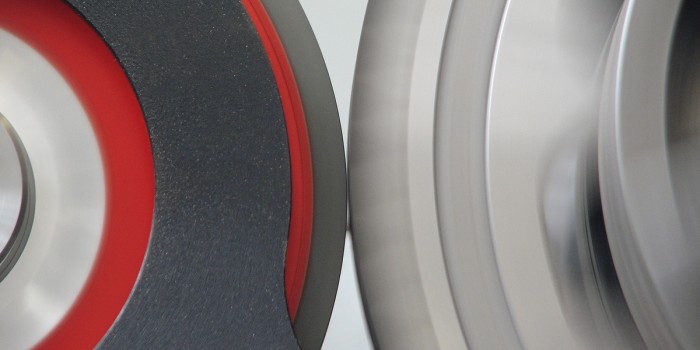

| Grinding wheel dia. |

mm

in |

640

/ 762

25 / 30 |