Laser metal deposition in batch production

Laser metal deposition (LMD) is a thermal coating process where metal powder is melted by a laser beam and directly applied to a component. This process allows for the creation of functional surfaces with high adhesive strength, wear resistance and defined geometry.

Unlike galvanic or thermal spraying processes, laser metal deposition forms a metallurgical bond with the base material, without significantly affecting the component internal heat.

EMAG solutions for perfect coatings

The future of brake disk technology

The new European emission standards pose major challenges for the automotive industry. The Euro 7 standard, which will apply to all vehicle types from November 2027, introduces strict limits for brake dust emissions:

- 7 mg/km for conventional vehicles

- 3 mg/km for electric vehicles

Laser coating technology (LMD - Laser Metal Deposition) provides a reliable solution to this challenge, effectively doubling the service life of brake discs.

Single vs. dual-layer systems for hard coating of brake discs

Two variants of laser metal deposition of brake discs are commonly used in industrial practice: Single-layer systems and two-layer systems.

Single-layer systems consist of a single layer in which carbides (e.g. titanium carbide) are embedded directly in a stainless steel matrix. They are particularly suitable for smaller and lighter vehicles where the thermal and mechanical stresses on the friction surface are moderate. Their advantages inlcude shorter cycle time and lower production costs.

Two-layer systems, in contrast, feature a separate adhesive layer - usually a corrosion-resistant stainless steel matrix – with an overlying friction layer. The latter is specifically designed for wear resistance and friction coefficient. By separating the functions, the friction layer can withstand significantly higher loads. This makes two-layered systems the preferred solution for SUVs, high-performance vehicles or commercial vehicles.

The selection of coating system depends on factors such as the vehicle type, required service life, application profile and expected brake pad pairings. Generally, two-layer systems offer greater process reliability and allow for a more targeted optimization of service life and emission values.

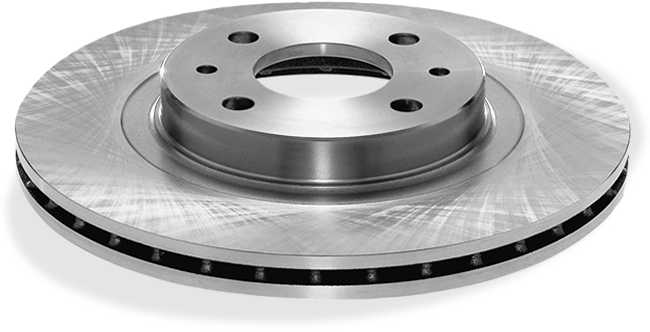

Laser-coated brake disk. The precision laser coating enables a significant reduction in brake dust emissions and considerably extends the service life.

Two-layer system for maximum performance

Advanced laser coating technology creates a precision layer system:

Adhesive layer:

- Stainless steel matrix

- Layer thickness: 100-150 μm

- Guarantees optimum bonding to the base material

Friction layer:

- Titanium carbides in stainless steel matrix

- Layer thickness: approx. 250 μm

Provides excellent wear resistance and friction properties

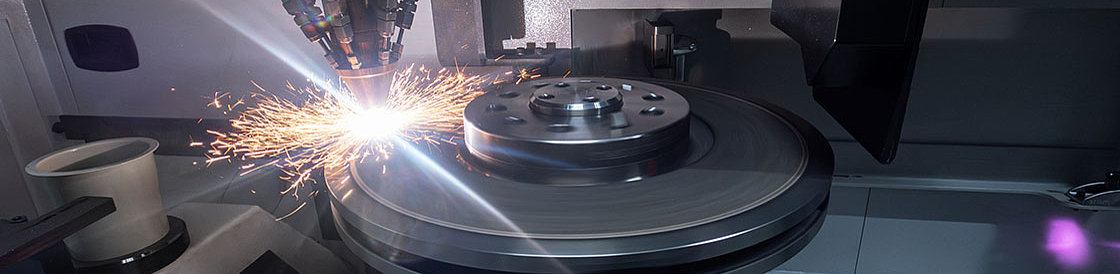

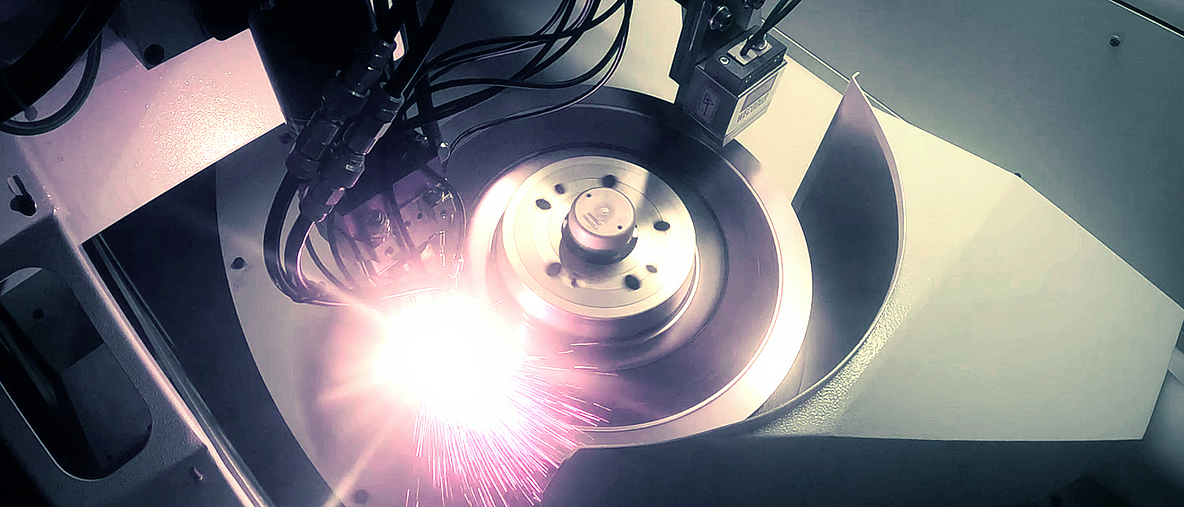

Laser metal deposition of a brake disk with the ELC 450 LMD machine from EMAG during the coating process

Advantages Laser metal deposition for brake discs

- High coating quality: Pore-free and crack-free coatings with defined properties

- Local application: Coating only where it is functionally necessary

- Resource-efficient: high powder utilization (up to 95%)

- Can be monitored digitally: process data such as coating thickness, laser power and melt pool size can be recorded inline

- Versatile: Suitable for cast iron, steel, stainless steel and other metallic materials

- Minimal rework: controlled coating thickness reduction minimizes the amount of grinding required

Grinding process and process integration

Grinding coated brake discs reduces the surface roughness from 60 µm to the functionally required 5 µm. Precision coordination between the coating and grinding processes is crucial, as the distortions caused by laser metal deposition must be compensated for while maintaining tight tolerances for axial run-out and thickness fluctuations. The elastic deformation of the brake disc during grinding poses a particular challenge, as optimum process forces must be found. Data-based process integration can reduce wear on the grinding wheels by up to 30% and significantly improve the cost-effectiveness of the overall process chain.

Workpieces

The Right Manufacturing Solution for Every Workpiece

Machines for your requirements

(2) machines found