02/27/2024 - Oliver Hagenlocher - Customer Stories

Bharat Forge Daun relies on EMAG: Perfecting the entire machining process on the stator housing

Unusually sophisticated components and high-strength materials for high-tech applications, like stator housings for electromobility with ensured quality in the range of microns, are among the machining challenges tackled by the specialists at Bharat Forge Daun. Right in the middle of it all: Several vertical turning machines from EMAG, which are in operation around the clock, five days a week. With production demands like these, it is obvious that service from EMAG is particularly important. But what exactly was the deciding factor in the decision to invest in these machines?

Images

Complexity is something of a hobbyhorse at Bharat Forge Daun: The company, based in the heart of the Eifel region, around 50 kilometers from Koblenz, produces rotationally symmetrical series components as a contract manufacture as well as tools and moulds, which are then used by the forging experts at Bharat Forge CDP and Bharat Forge Aluminiumtechnik, for example. This means that challenges like difficult surfaces and positional arrangements are common. "Extreme accuracy requirements in the micrometre range are always part of our work," says Christoph Steffens, Head of Mechanical Engineering at Bharat Forge Daun, summarizing the initial situation. "In this context, we monitor the processes very comprehensively, carry out many measurements and even accompany the component development on request - so that the production of the component runs efficiently. We offer this expertise on the market for sectors such as the automotive industry, general mechanical engineering and the production of agricultural machinery."

Efficient machining of forged stator housings

A stator housing used in the hybrid drive of a large German automotive company shows what this means in concrete terms. Even at first glance, it is clear that its pot-like shape and various geometric details are sophisticated. What's more, the blank is a forged steel component - a rarity in this field of application. Its material properties are an additional challenge for the south-west German machining experts. In addition, the client has continuously increased the required quantities over the years (and will continue to do so). So how do you combine accuracy, efficiency and process reliability in this environment? Bharat Forge Daun's answer has a lot to do with EMAG's mechanical engineering components, as the specialists have been relying on EMAG lathes for some time.

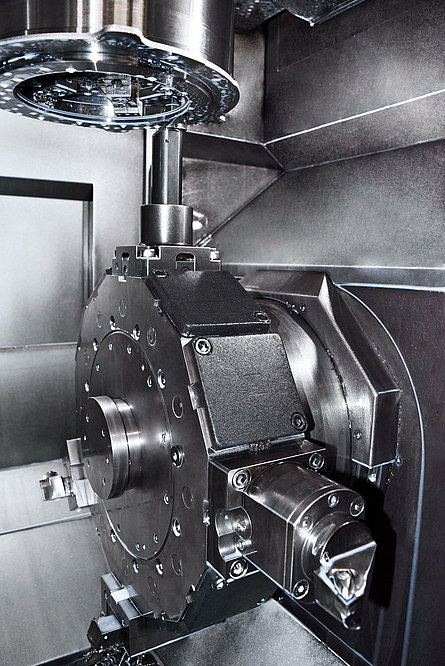

Vertical design with decisive advantages

The vertical design of these solutions played an important role in the investment decision. The horizontal machine from another manufacturer had caused some difficulties in the past. For example, annoying chip clusters regularly formed, which had to be removed manually two to three times per shift. "It was therefore obvious to us that we should carry out these processes in machines with a vertical design, because their unhindered chip flow prevents many disruptions. Our objective was to achieve maximum process reliability," emphasizes Steffens. The decision in favor of EMAG was also based on existing know-how: The machine manufacturers used examples from other customers to show how stator machining is carried out in their machines - with low non-productive times and high-precision handling processes. Integrated automation including a pick-up spindle and lateral conveyor belt ensures fast processes, while the stable base body made of the polymer concrete Mineralit® stands for quality in turning and milling processes.

EMAG service in focus

Last but not least, the response time and the expertise of EMAG's service department play an important role for Bharat Forge Daun. A regional service technician is always on site within a few hours and solves any problems directly. "The machines are very robust. Nevertheless, this issue is important because we produce five days a week in three-shift operation and so far we have always been helped with minor faults in record time - for example with a defective light barrier. The repair has never taken longer than two hours," says Christoph Steffens, who also reports that EMAG has already been on site via remote service.

Contact

Oliver Hagenlocher

Area

Press and Communication