Optimize production processes with EDNA ONE

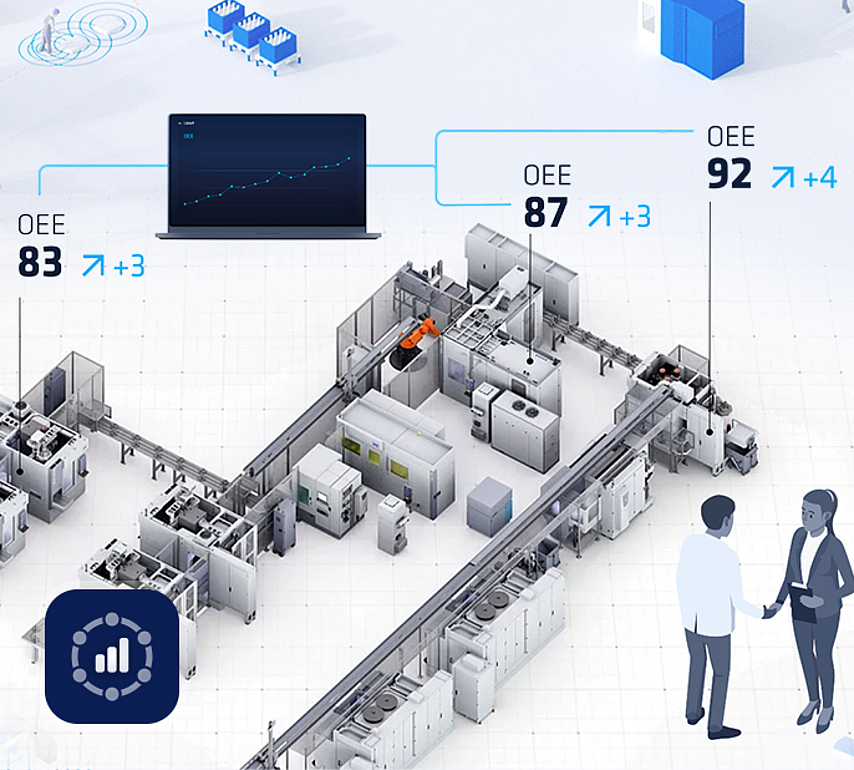

Take advantage of the opportunities offered by the digital factory and make your production processes more efficient, flexible and transparent. By integrating intelligent machine technologies, automated processes and targeted data analysis, you can sustainably optimize your production and increase your OEE (Overall Equipment Effectiveness) at the same time.

With EMAG's EDNA solutions, you can make your CNC turning machines fit for Industry 4.0: The EDNA Cortex acts as a central, secure data interface for aggregating and providing all machine and process data, the Workpiece Data Recorder enables cross-technology analysis of workpiece-specific parameters, and with EDNA Process Consulting, you can identify the potential of your production through targeted expert advice.

Smart machines for efficient production

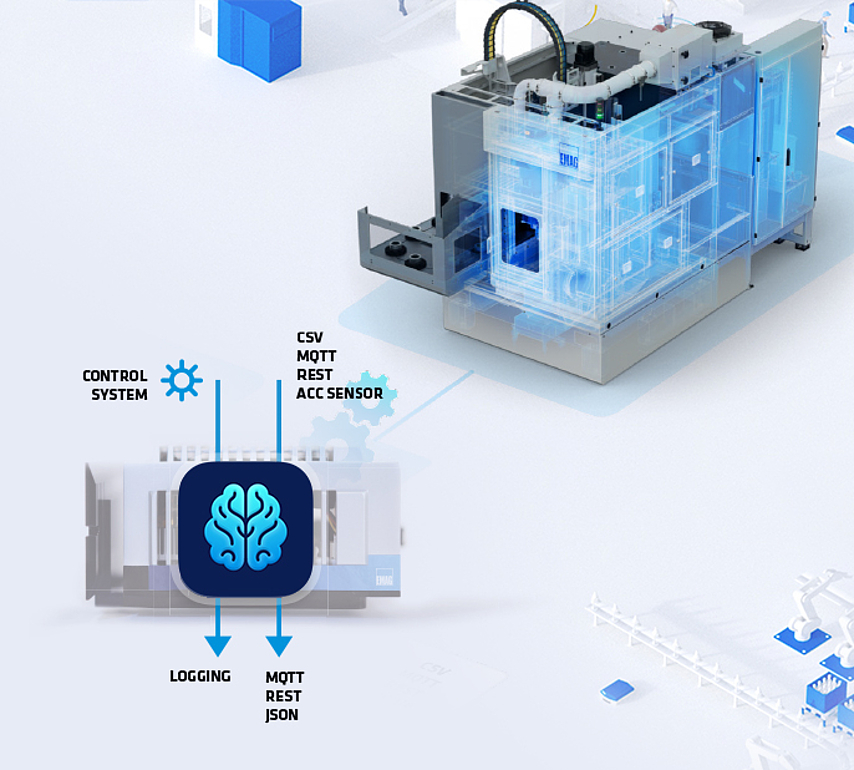

EDNA Cortex: Central data interface

EDNA Cortex gives you secure, quick and easy access to all of your machine's process data. As a central data interface, EDNA Cortex connects all relevant data sources and offers a comprehensive history of machine data over several months. The operating data can be conveniently accessed via common standard interfaces (OPC-UA, MQTT, REST, CSV). The highly flexible data format ensures maximum compatibility and simple integration.

Advantages of EDNA Cortex:

- Central interface to control and operating data

- Historical data storage for better traceability

- Cross-technology data communication (grinding, turning, ECM, laser processing)

- Simple export options for machine data (one-click CSV download)

- Flexible data provision

EDNA Workpiece Data Recorder: Detailed workpiece analysis

The EDNA Workpiece Data Recorder visualizes and analyzes workpiece-related data in order to optimize your process development across all technologies. The clear assignment of process data to the workpiece improves transparency and enables data-based process optimization.

Advantages of the EDNA Workpiece Data Recorder:

- Increased efficiency through direct data allocation

- Complete traceability of the production process

- Comparability and optimization across multiple technologies

- Reduction of operating costs through efficient process control

EDNA Process Consulting: Expert knowledge for in-depth optimization

With EDNA Process Consulting, our EMAG experts identify waste and unused potential in your production process. The combination of data-based analyses and in-depth expert knowledge provides you with deep, fact-based insights into your processes.

Added value through EDNA Process Consulting:

- Analysis of the actual production process and targeted identification of optimization potentials

- In-depth, fact-based insights thanks to machine data

- New insights through the interplay of expert knowledge and data-based analysis

EDNA ONE simplifies machine operation, automates servicing and maintenance and offers comprehensive options for process optimization through intelligent functions and IoT integration. The direct analysis and monitoring of machine data such as cycle time and process information on the workpiece enables a targeted and fast response and troubleshooting.

Optimize your production processes and sustainably increase your competitiveness with digital solutions from EMAG.

Contact IoT

Do you have questions or need more detailed information? Please contact us!

iot@emag.com