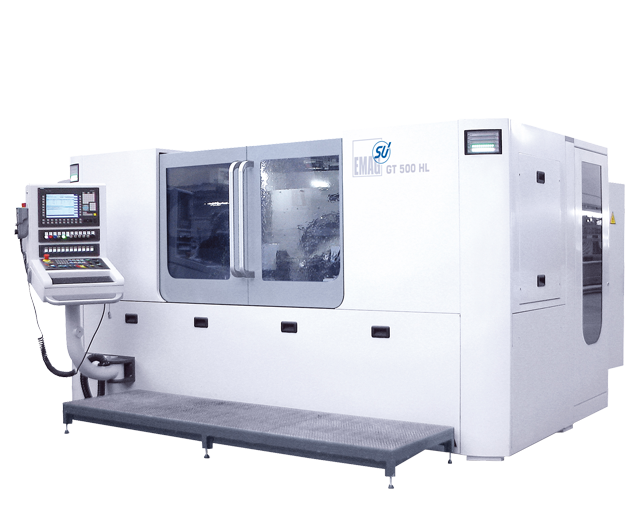

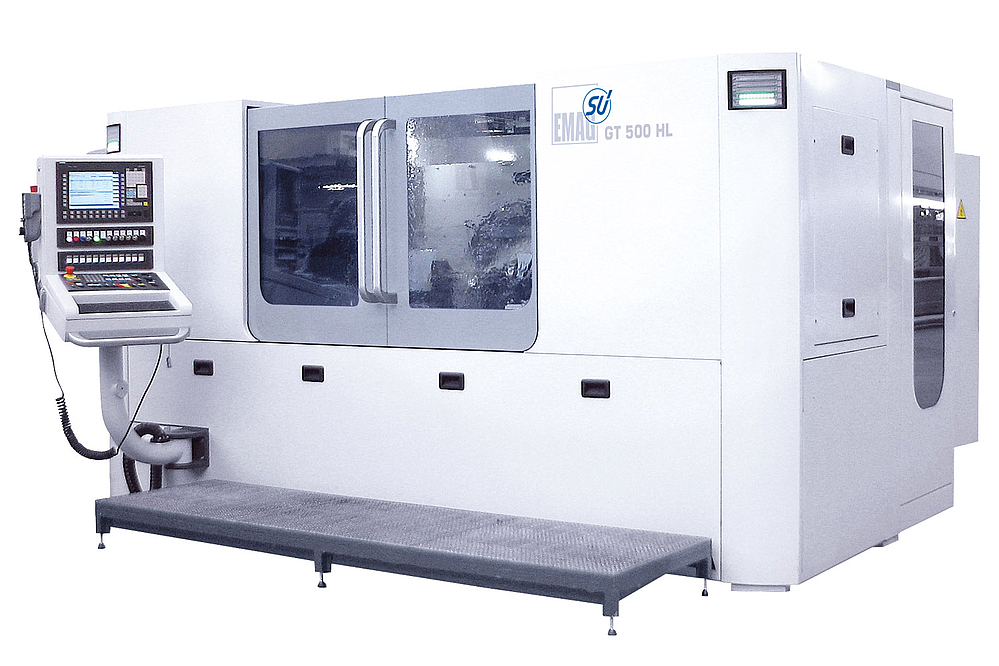

Gear Profile Grinding Machines

GT 500 HL

- Module range: mm 0.5 - 35.0

- Workpiece dia., max.: 380 mm | 15 in

- Workpiece length, max.: 1,150 mm | 45.5 in

Screw Profile Grinding GT 500 HL

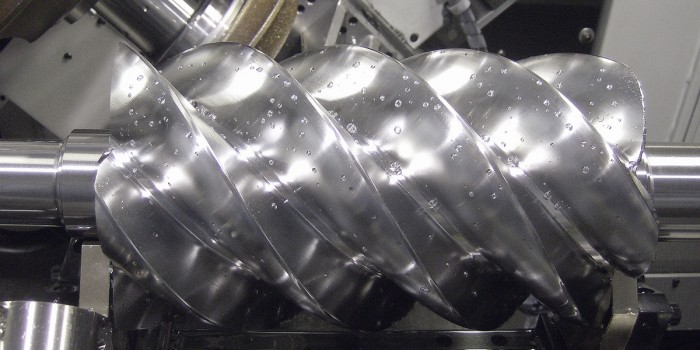

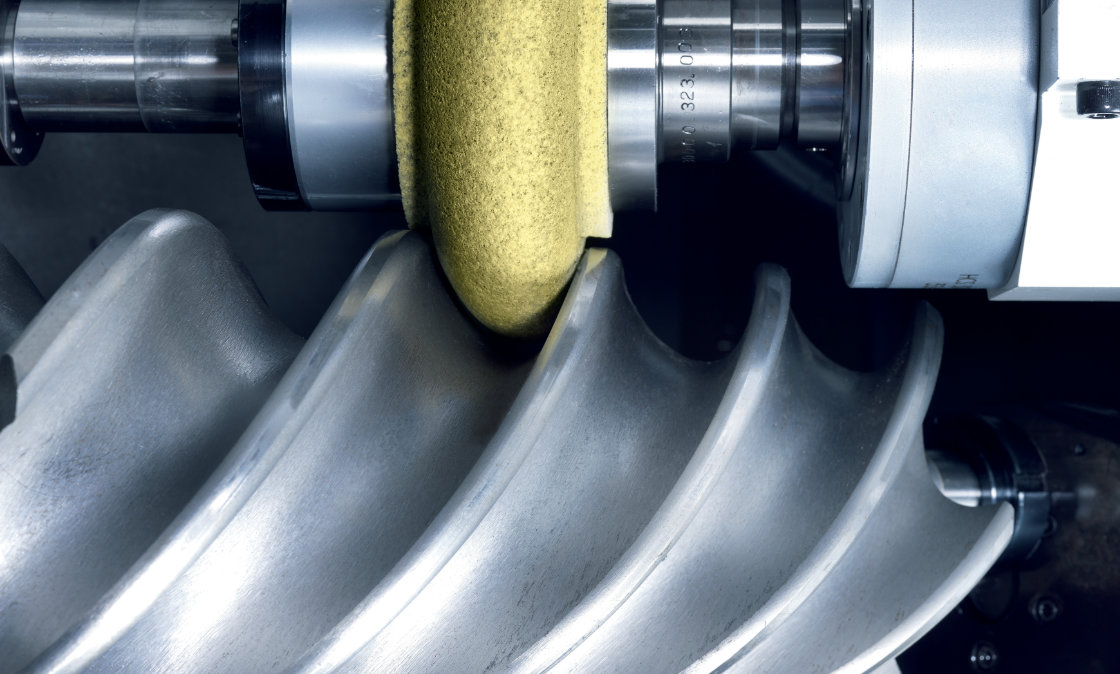

The GT 500 HL is suitable for the manufacture of very large screws and rotors.

Manufacturing of very large screws and rotors

The GT 500 HL screw profile grinding machine is suitable for the manufacture of very large screws and rotors.

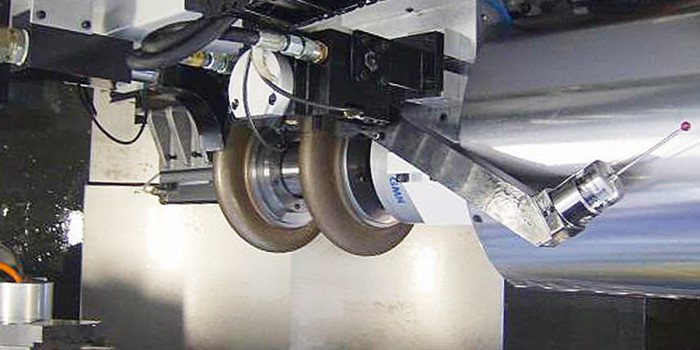

Especially suitable to grind with CBN, the GT 500 HL also facilitates working with dressable ceramic wheels or even combinations of the two.

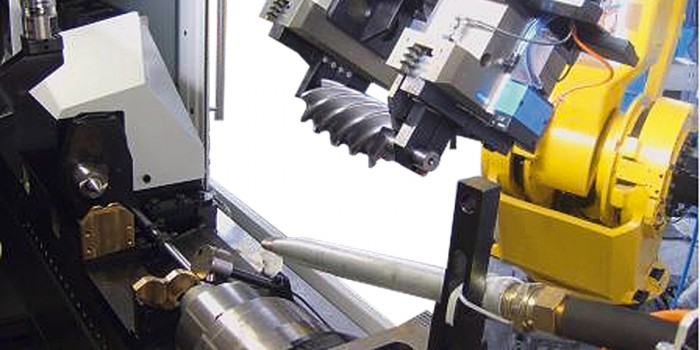

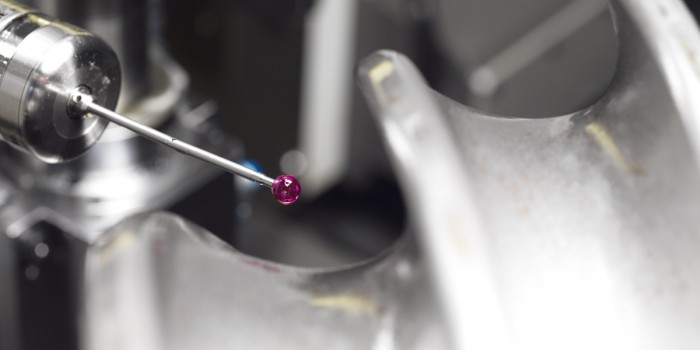

An integrated measuring unit also makes the correction on board. For more efficient handling, you can link the GT 500 HL to an external robot device and connect it directly with an external measuring unit.

Like the GR gear profile grinding machine, the GT 500 HL comes with a rotor-specific software package, developed under real manufacturing conditions.

Advantages GT 500 HL

- Special machine version for the manufacture of large rotors

- Extra powerful main spindle for high stock removal

- Double tool setup for roughing and finishing on one spindle

- Tried and tested rotor manufacturing software

- Integrated measuring

- Connection with measuring unit by means of external PC software for the closed loop manufacturing checking

- With a single grinding, wheel profiles with a depth of 120mm and width over 200 mm can be grinded

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Profile grinding of gears and long, slim and toothed components is performed discontinuously, i.e., tooth gap by tooth gap, is completed one after the…

Technical Data

Module range

0.5 - 35.0 mm

Workpiece dia., max.

380 mm

15 in

Workpiece length, max.

1,150 mm

45.5 in

| Module range | mm | 0.5 - 35.0 |

| Workpiece dia., max. |

mm

in |

380

15 |

| Workpiece length, max. |

mm

in |

1,150

45.5 |

| Profile depth, max. |

mm

in |

80

3 |

| Centre dist. work spindle / tool spindle |

mm

in |

33

/ 460

1.5 / 18 |