Machining differential cases with high efficiency

Turning complex differential housings is a growing challenge, as production volumes are rising—the component will also remain indispensable into the future, for all propulsion systems. EMAG develops production lines with ultrafast processes.

Differential cases: ultrafast machining with EMAG

High production volumes, error-free processes, short cycle times—the production of differential housings naturally has to meet the high requirements typical of the automotive industry. On top of that, however, this central connecting element in the differential also has a very complex shape. The turning operation is therefore quite demanding and involves a number of subprocesses. Moreover, there are various different versions of the component, such as closed full-sphere cases, half-sphere cases, and open cases with a cover.

Modular system is a winner

EMAG has specialized in the machining of this component for many years now. Its mechanical engineers develop end-to-end production lines based on its modular machine platform. These lines make use of standardized and proven pick-up machines that can be interlinked easily using EMAG's own TrackMotion system. The result is an ultrafast, reliable process with little non-productive time. With its vertical turning machines, the line also requires very little space.

Line cycle completed in just two minutes

A total of three or four operations are performed on an EMAG line of this kind—depending on the component version and blank in use. If the component undergoes an initial rough machining process at the foundry or forge shop, all the part manufacturer needs to do for a closed case (for example) is just three more operations. These comprise turning operations on the outside and inside of the differential housing, and various drilling processes. Measuring and positioning units and cleaning systems complete the production line. The line cycle is completed in just two minutes.

EMAG VL machines excel

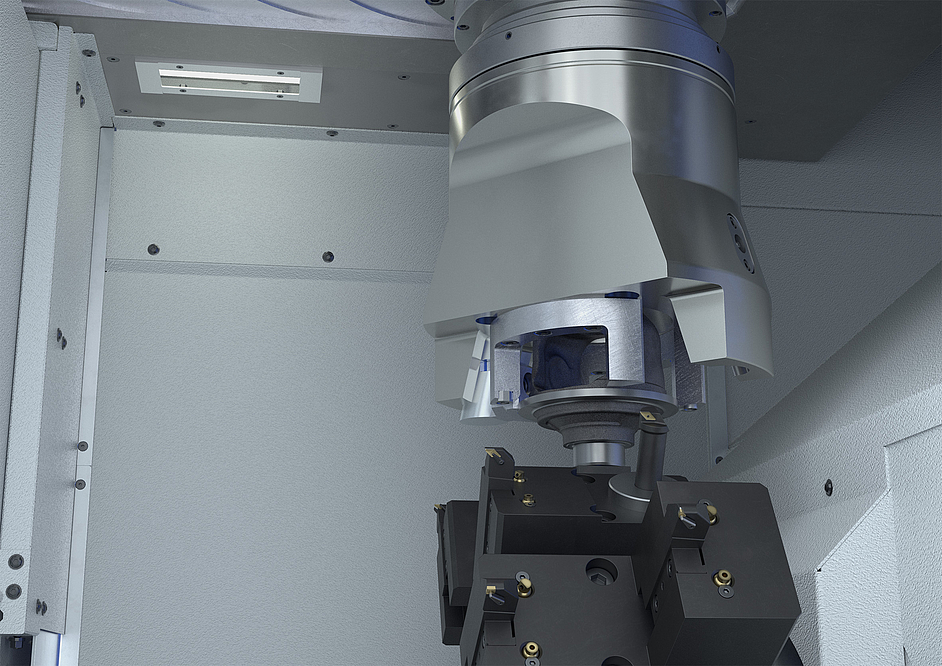

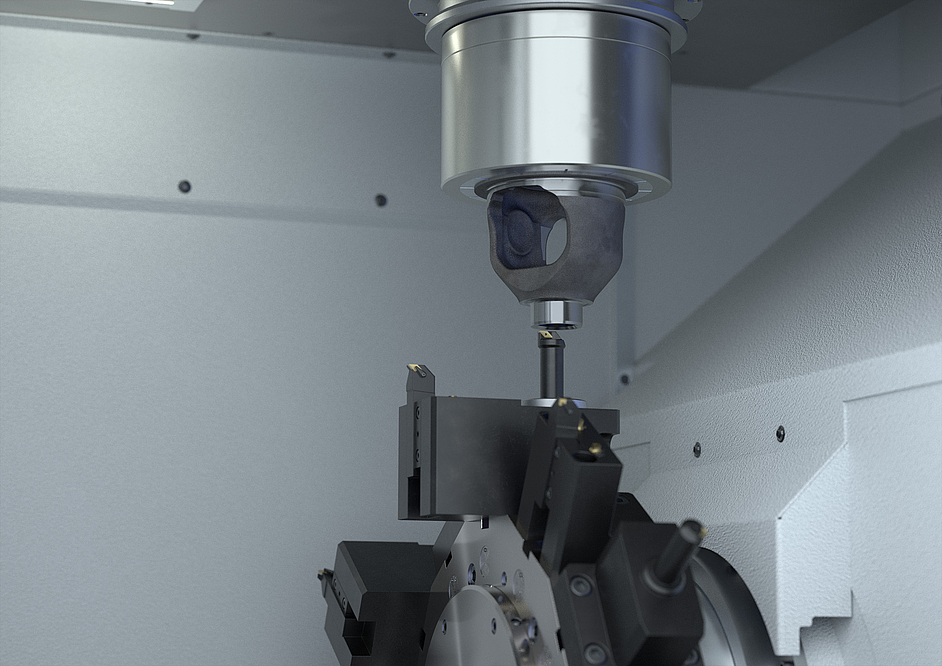

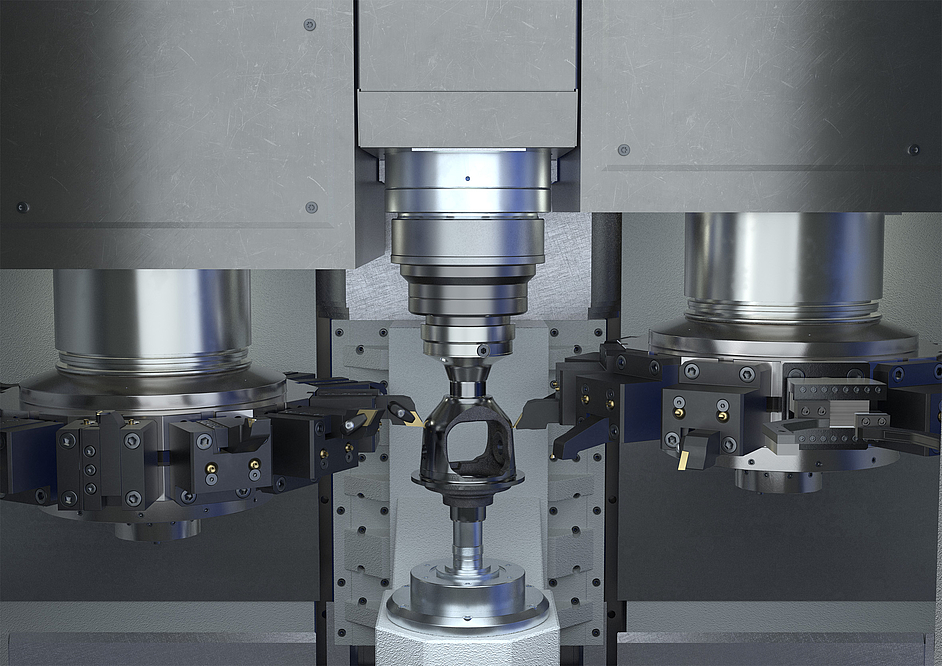

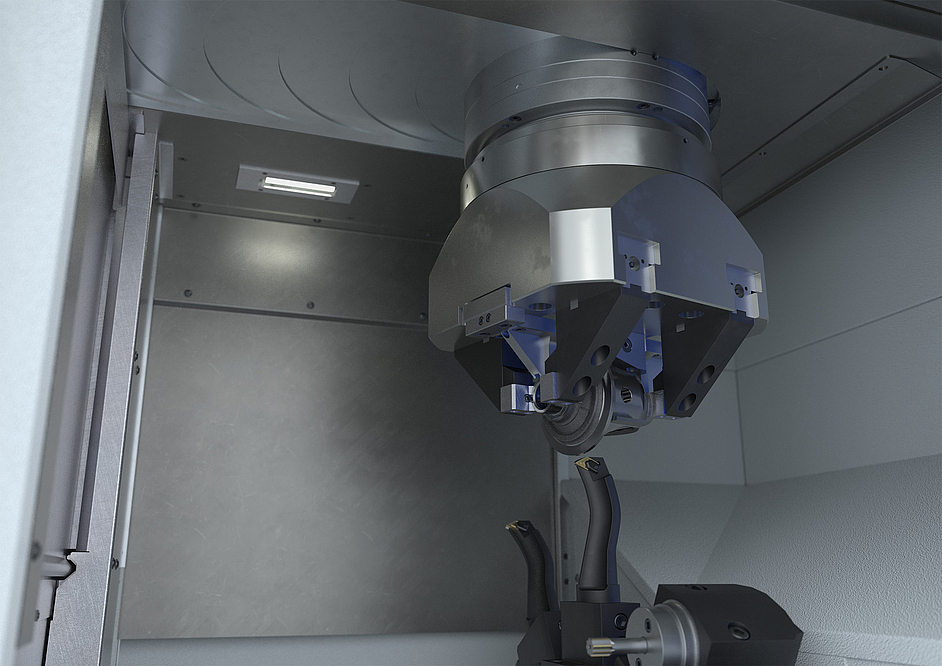

What does the layout of a line like this look like in detail? The example displayed here shows the machining of a full-sphere differential housing. The process has been distributed across four Modular Solutions machines in order to achieve the best possible cycle time. In OP10 and OP20, the two sides of the case are turned on a VL 4 vertical turning center. For the complete machining of the outside in OP30, EMAG uses the VT 4. It allows for four-axis machining to be performed on the entire outside surface in a single clamping position. This technique ensures not only a rapid machining process, but also especially high quality as it eliminates the occurrence of positioning errors when changing the clamping position. Then, in OP40, another vertical turning machine is used, this time a VL 6. For this machining step, the differential housing is clamped at a 90° angle for fine machining of the drilled hole and the inside of the spherical cap. To achieve this task, as for all the other operations, EMAG uses a chuck specially created for this workpiece.

Half-sphere differential housing

The setup would look different for a closed half-sphere differential housing. This time, the process would begin in OP10 with the turning of the first side on an EMAG VL 6. The turning of the second side (OP20) and a drilling process are carried out on a second VL 6. Up to this point the two processes hardly differ. However, the final inside machining of the half-sphere (OP30) is interesting: EMAG’s specialists opted for a VSC 250 DD with specially designed tools to achieve this task. The result is an exceptionally short machining time: this inside turning process is completed in just about 125 seconds.

High-strength welds with EMAG laser welding technology

The differential housing clearly shows the possibilities laser welding technology has in the general development of the automotive industry. For example, for some time now the screw-type connection between differential housing and crown gear used by the German automotive industry has been replaced with a welded connection. This reduces the material volume – an important cost factor, considering the enormous numbers of these components produced. At the same time, the weight of the differential housing has been reduced by approximately 1.2 kg. Looking at the progressive concentration on lightweight constructions in the automotive sector, this represents an enormous saving. Manufacture of the differential housing is a typical and an ideal example. EMAG laser welding technology generates high-tensile welded joints that can replace the classical connections in many areas of application and thus reduce the cost of materials.

Advantages Differential housing

- Less weight

- Lower costs

- Improved component quality

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Laser cleaning is a fast and space-saving process that can replace conventional washing machines in many applications. One of its main strengths is…

Laser welding is a precondition for compact, weight-optimised components and thus for energy- efficient vehicles. Adjustable doses of concentrated…

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process…

Machines for your requirements

(4) machines found