Digitalization EDNA ONE

Increasing digitalization is fundamentally changing the manufacturing industry. Today, companies are faced with the challenge of continuously optimizing their processes, minimizing downtimes and at the same time reacting flexibly to changes. With EDNA ONE, EMAG offers a comprehensive digital solution that is precisely tailored to these requirements. Increase efficiency, flexibility and transparency in your production and secure your long-term competitiveness.

EDNA – Industry 4.0 Ecosystem: EDNA forms the basis for all our developments. EDNA, which stands for EMAG DNA, is a modular software ecosystem consisting of networked software and machine components.

Digital solutions for efficient and future-proof production processes

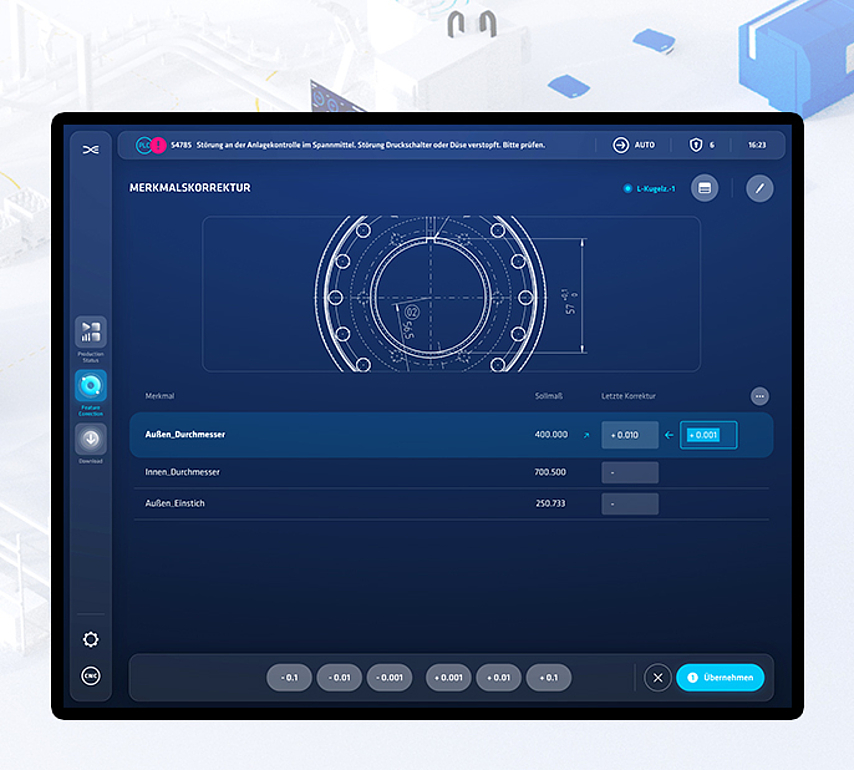

Simplified machine operation and setup with EDNA ONE

Simplify the operation and machine setter of your production systems with the intelligent technologies from EDNA ONE. Our digital solutions reduce complexity, minimize errors and relieve your machine operators through intuitive interfaces and real-time display of all relevant production data. Increase the precision, process reliability and efficiency of your machines - easily and reliably.

Your advantages at a glance:

- Reduced operator complexity thanks to intuitive controls

- Real-time display of all relevant production data

- Efficient planning and implementation of tool changes

- Sustainable increase in your overall equipment effectiveness (OEE)

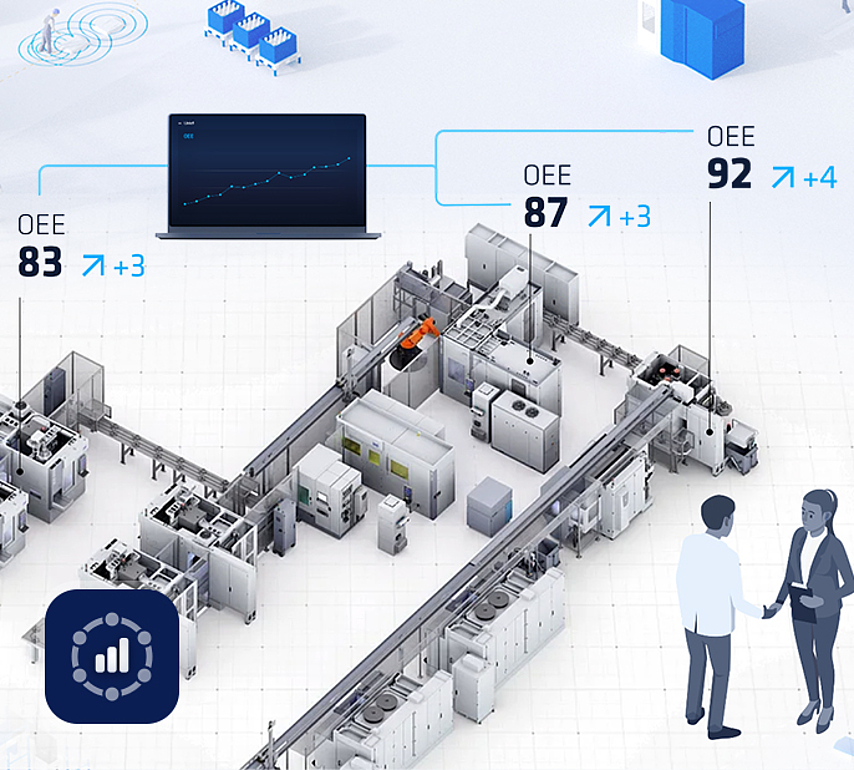

Optimize production processes with EDNA ONE

Optimize your production sustainably through targeted digital process control and in-depth analysis of your production data. EDNA ONE networks your machines and offers detailed workpiece-related analyses and data-based process optimization. Improve transparency, increase the efficiency of your production processes and reduce your operating costs in the long term.

Your advantages at a glance:

- Transparent, cross-technology process optimization

- Comprehensive historical data collection and evaluation

- Workpiece tracking across all production steps

- Expert support for data-based production optimization

- Significant increase in overall equipment effectiveness (OEE)

Automate maintenance with EDNA ONE

Reduce unplanned downtime and increase the availability of your machines with the digital analysis solutions from EDNA ONE. Proactive condition monitoring and automatic diagnostic tools allow you to detect problems before they arise. Use intelligent systems for predictive servicing, sustainably reduce service costs and ensure consistently high production quality.

Your advantages at a glance:

- Predictive servicing through continuous condition monitoring

- Minimization of unplanned machine downtimes

- Proactive spare parts planning and service planning

- Reduced servicing and operating costs in the long term

Contact IoT

Do you have questions or need more detailed information? Please contact us!

iot@emag.com