Gear Cutting Machines

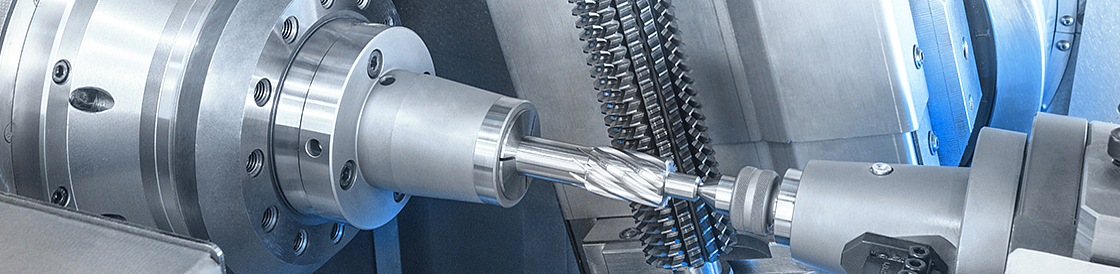

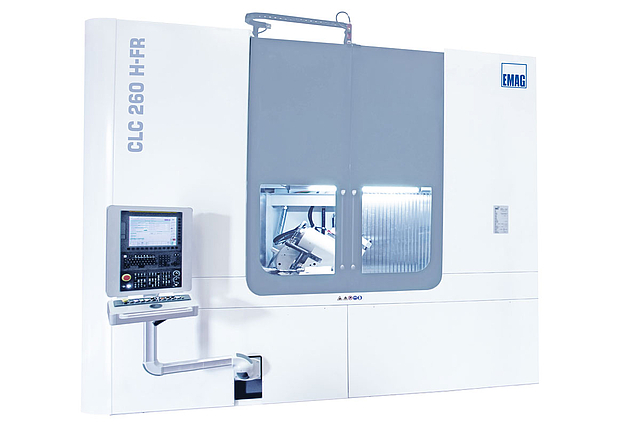

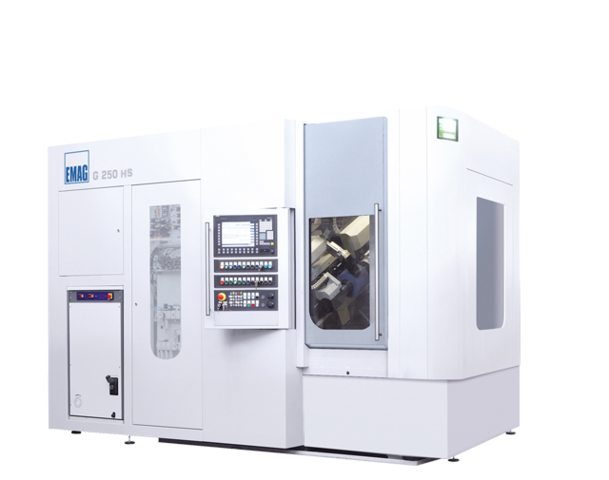

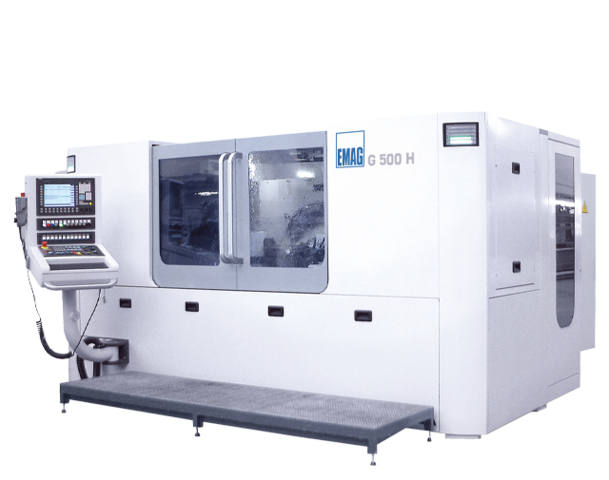

EMAG is known as a supplier of top-quality gear hobbing technology for high-efficiency gear production. EMAG has the right solutions for gear production: cutting-edge gear hobbing technology and the complimentary machines for chamfering and deburring.

With EMAG SU (former Samputensili), EMAG is systematically expanding its scope of technology by adding a range of gear production methods: shaving, shaping, tooth flank grinding, profile grinding and generating grinding.

Overview Gear Cutting Machines from EMAG

(25) machines found