Manufacturing systems for 120 mm tank ammunition and artillery shells

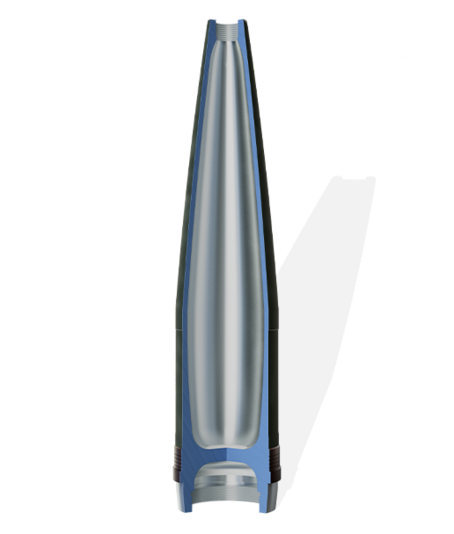

With its vertical VL 8 pick-up turning machines, EMAG offers customized manufacturing systems for the demanding machining of 120 mm tank ammunition and artillery shells. Our expertise in machining guarantees maximum dimensional accuracy and surface finish - decisive factors for the functionality and reliability of modern ammunition components.

High-precision machining of 120 mm armor-piercing ammunition with the EMAG VL 8

Line concepts for every batch size

Line concept | Casing | 2 x VL 8 - Flexible solution for small batches

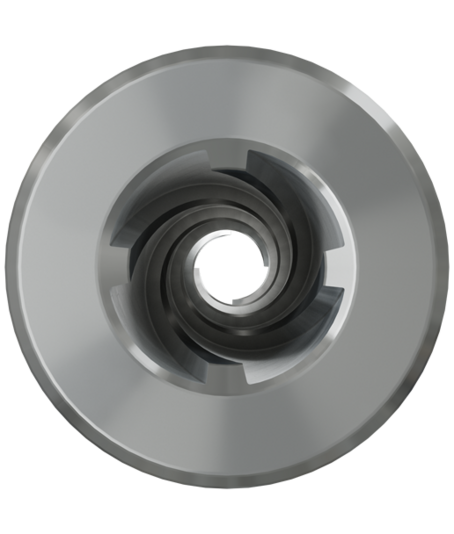

The production line with two VL 8 machines optimally combines flexibility and efficiency. Parts can be handled between the two machines either manually by the operator or automatically using TrackMotion. The machining of the shell is carried out in two operations, consisting of precision turning and drilling.

The advantages:

|

Line concept | Casing | 4 x VL 8 - Efficient and automated for medium batches

The production solution with four VL 8 machines offers a balanced ratio between three OP 10 and one OP 20 machine. The result is fully automated production with low support requirements.

The advantages are:

|

Line concept | Casing | 16 x VL 8 - Fully automatic large-scale production

The complex production line consisting of 16 VL 8 machines is specially designed for large batches and enables fully automated production including parts cleaning and centralized loading and final stacking of the workpieces.

The main advantages are:

|

Machines

(1) machines found

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process…