Classic – Shafts – USC/HSC

HSC 1

- Axes: X / Y / Z + C (2×)

- X-axis travel: 198 mm | 8 in

- Y-axis travel: ± 50 mm | ± 2 in

CNC lathe for two-stage machining processes with automatic spindle transfer

Technical highlights of the HSC 1 lathe

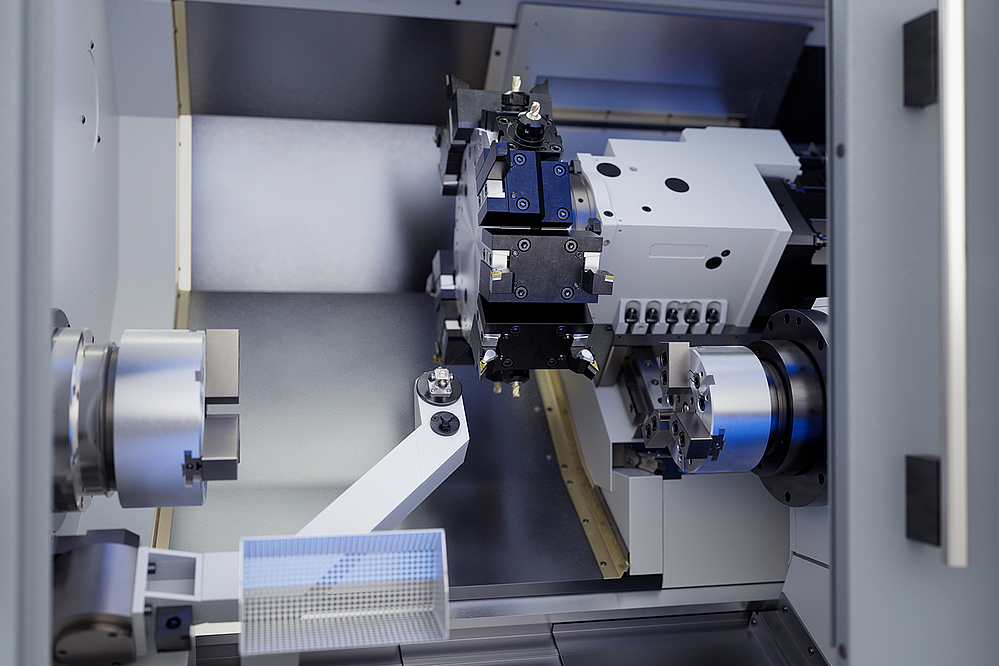

OP 10 / OP 20 machining with main and counter spindle

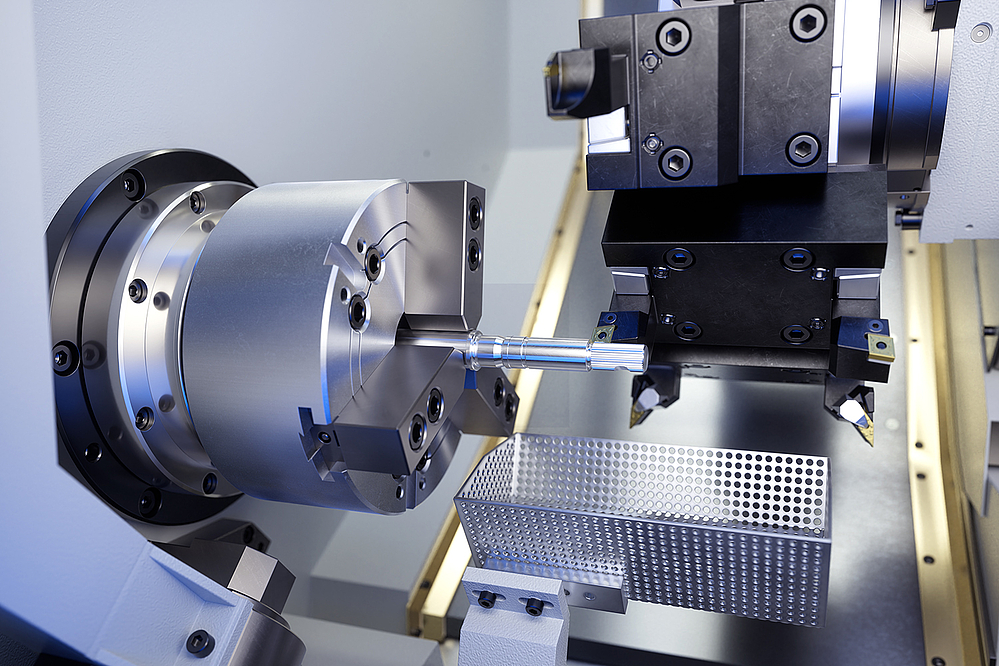

The main spindle (A2-6, Ø 63 mm spindle clearance) and the powerful counter spindle (Ø 110 mm flange) enable complete machining of both sides of the workpiece. Automatic part transfer between spindles increases process reliability and reduces manual intervention - ideal for medium series and complex turned parts.

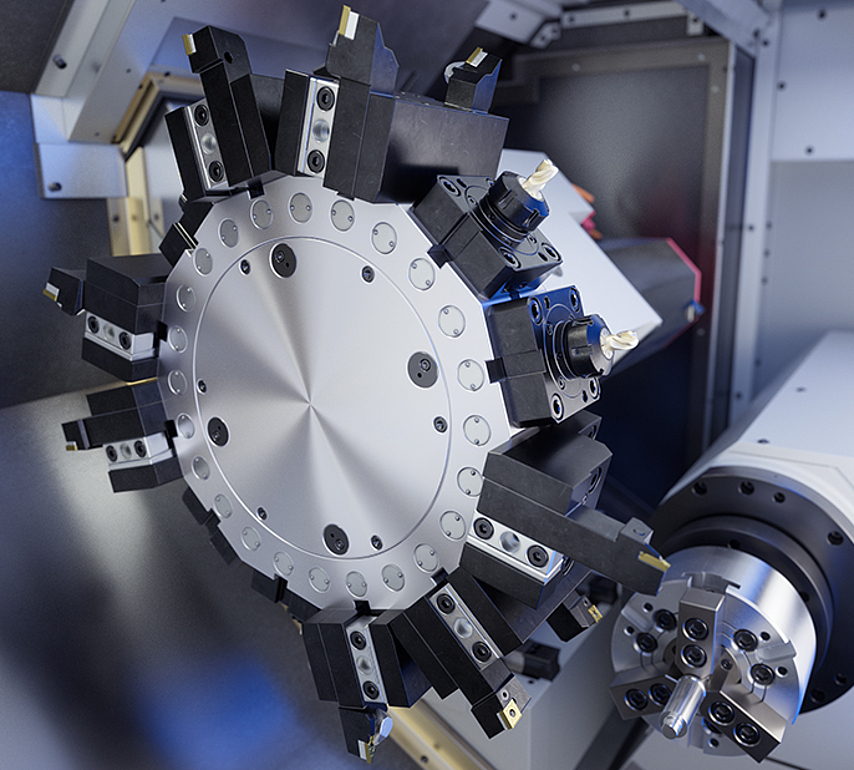

Milling operations using driven tools

The turret with 12 stations (BMT-55) can be fully equipped with driven tools. These reach up to 5000 min-¹ and enable integrated milling operations, e.g. cross drilling, feather key grooves or thread milling - without the need for secondary machines.

Full axis configuration incl. Y-axis

In addition to the linear X, Y and Z axes, the HSC 1 features C axes on both spindles. The true Y-axis with ±50 mm travel significantly expands the machining spectrum: even off-center contours can be produced cost-effectively.

The heavy, inclined bed base frame made of quality cast iron ensures low-vibration machining and optimal chip removal. Linear guides and preloaded ball screws guarantee dynamic movements with high positioning accuracy.

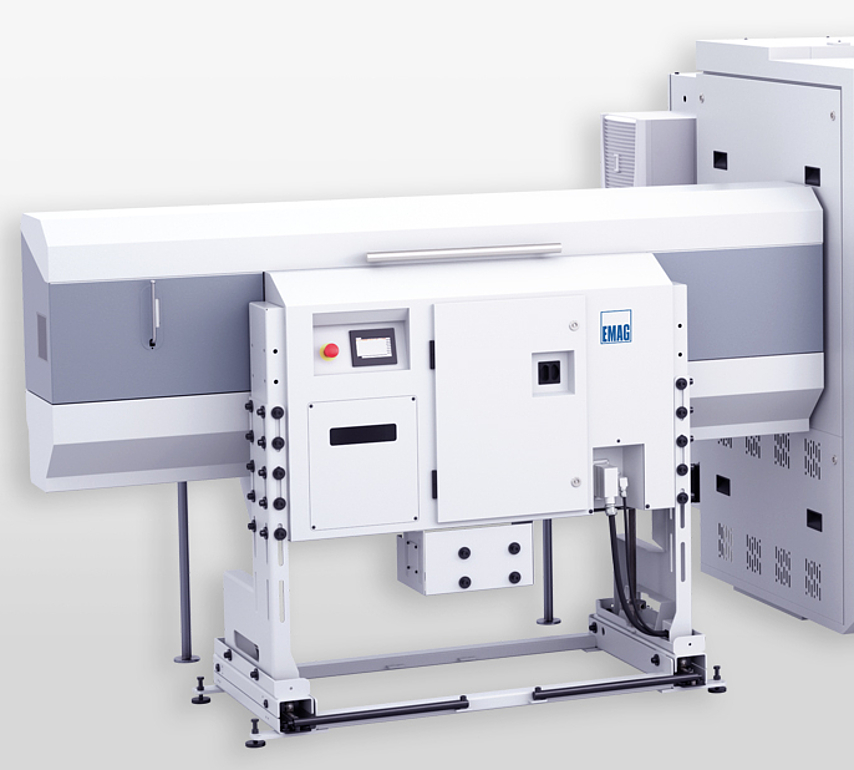

Automated bar processing with bar feeder

The HSC 1 can be optionally equipped with abar feeder for the batch production of turned parts from round material. Depending on the version (hydraulic or servo-controlled), this allows for automatic feeding of bars with diameters from 6 to 50 mm. This setup enables extended unmanned operation - ideal for high-volume production with minimal operator input.

User-friendly. Maintenance-optimized. Efficient.

The HSC 1 was developed not only for precision, but also for comfort:

- Swivel control panel (90°) for optimal view of the machine and controls

- Large doors & LED interior lighting for easy setup and monitoring

- Central lubrication points & excellent accessibility to all maintenance areas

- Tool life monitoring for maximum process reliability

Optional extensions for individual production requirements

The HSC 1 offers numerous optional configurations:

1. Turret with 16 stations (BMT-45 or VDI-30)

2. Big Bore spindle (Ø 74 mm) for larger diameter rods

3. High-pressure coolant systems (up to 25 bar)

4. Tool and workpiece probes

5. Mist separator & switch cabinet cooling

These options allow the lathe to be precisely tailored to your production needs.

Advantages HSC 1

- Machining on both sides (OP 10 / OP 20) via main and counter spindles

- Driven tools for integrated milling and drilling

- True Y-axis for off-center machining (± 50 mm)

- Automatic workpiece transfer between the spindles - no manual reclamping

- High rigidity fromsolid sloped machine base

- Servo turret with 12 stations (optionally 16) for broad tooling range

- Bar feeder option for unmanned batch production