Classic – Chucked Components – MSC

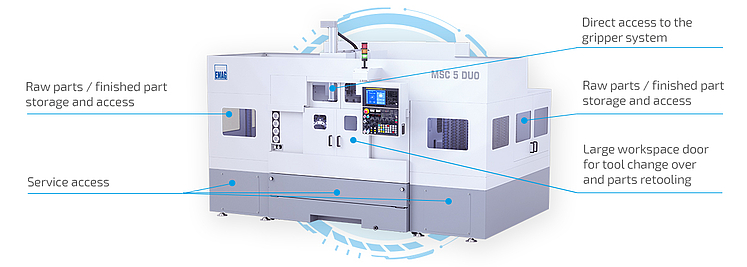

MSC 5 DUO

- Turning diameter, max.: 120 / 240 mm | 4.5 / 9.5 in

- Maximum turning length: 85 / 145 mm | 3.5 / 5.5 in

- X-axis travel: 130 mm | 5 in

Unmatched efficiency in automated batch production

Designed for maximum productivity: Advantages of the MSC 5 DUO lathe

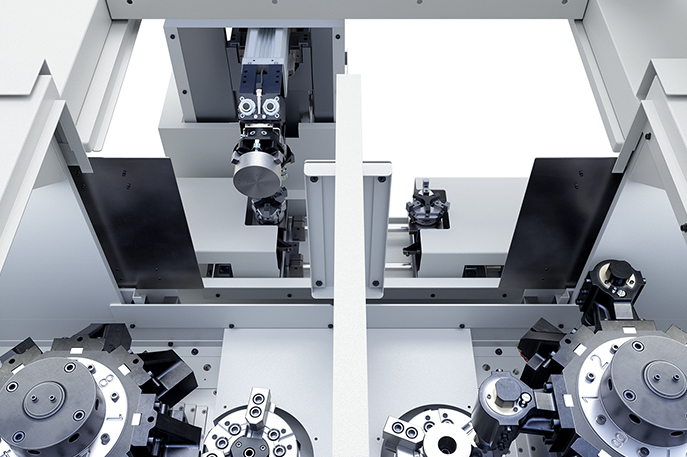

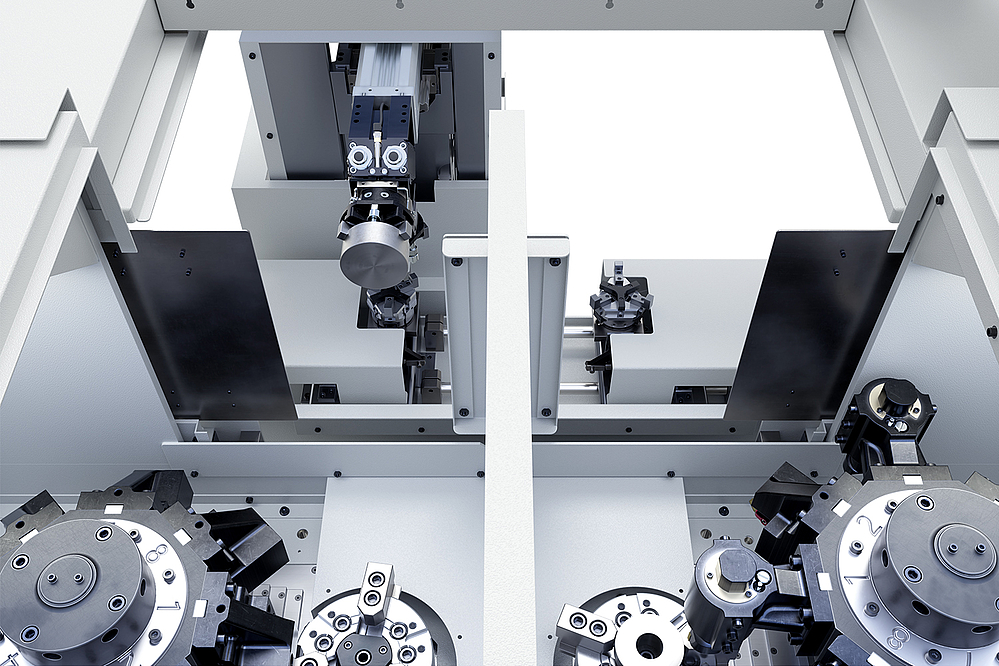

The MSC 5 DUO is designed for maximum productivity, allowing simultaneous machining on both spindles to reduce cycle times. Its integrated 3-axis gantry loading system ensures seamless part handling, minimizing idle time and boosting throughput.

- High productivity - Simultaneous machining on both spindles for faster cycle times

- Reduced non-productive time - Automated loading and unloading with a 3-axis gantry system

- Exceptional precision -Split-bed design limits vibration transfer for consistent accuracy

- Reliable performance – Thermally stabilized spindles ensure stable machining conditions

- Compact and efficient - Space-saving design allows for easy integration into production lines

- Optimized process reliability – Ensured by the intelligent coolant system and spindle monitoring

- Minimal downtime - Easy-access service components and clear fault diagnostics streamline maintenance

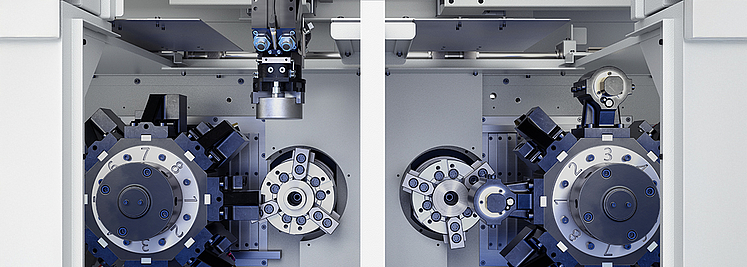

The split-bed design is the foundation of the MSC 5 DUO’s exceptional machining quality. By mechanically isolating the two work areas, it greatly reduces vibration transfer, ensuring consistent precision on both spindles, even in the most demanding production environments.

Main Features of the Machine:

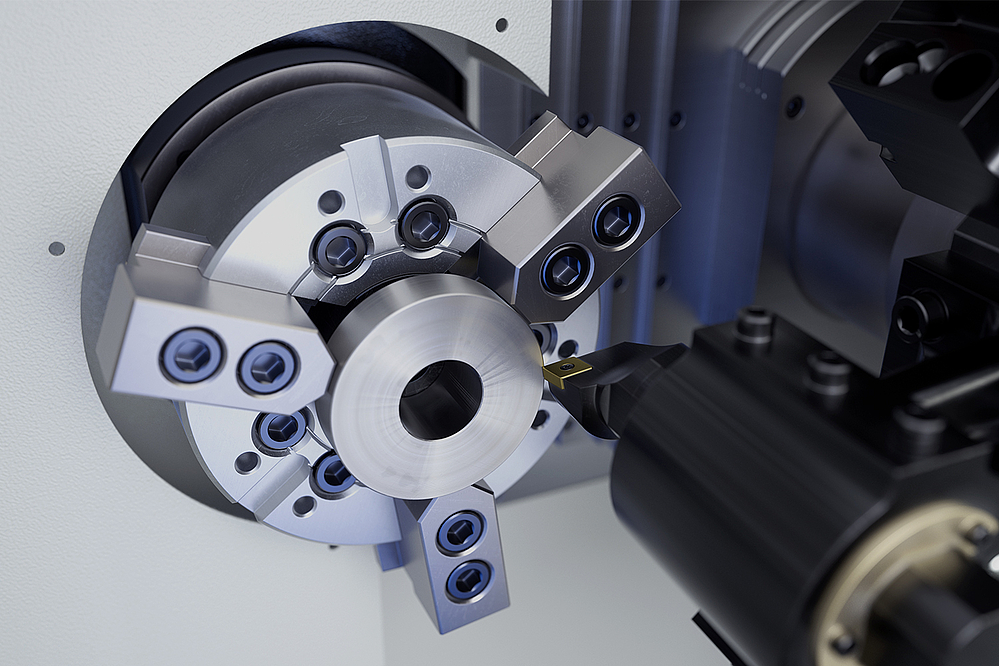

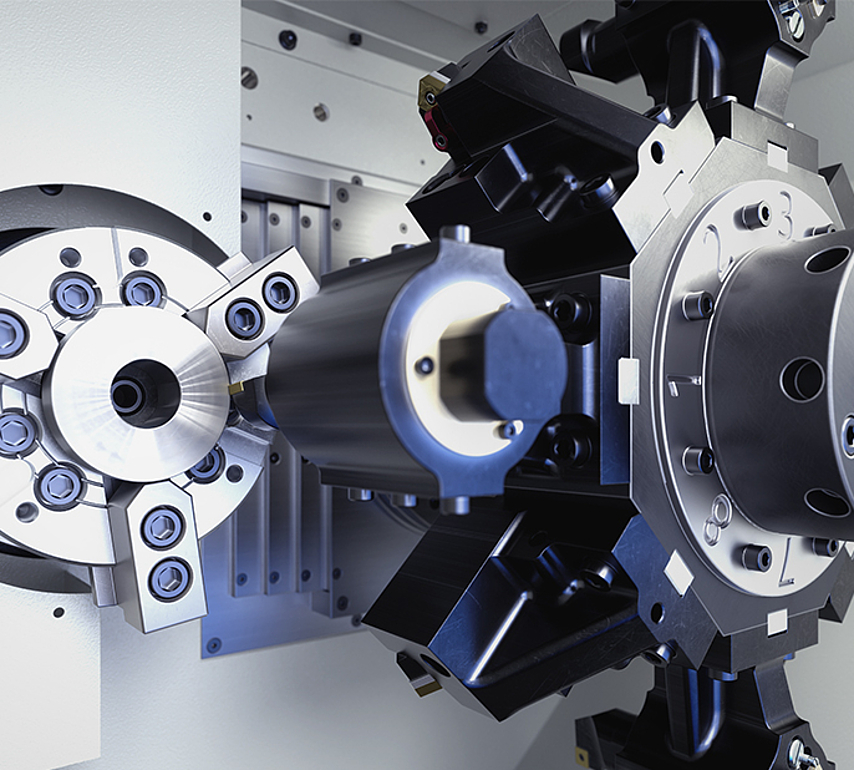

High performance spindles for versatile applications

The MSC 5 DUO is equipped with powerful, precision-engineered spindles designed to handle a wide range of machining tasks with speed, stability and efficiency.

Key spindle features:

- High-speed performance – Reaches upto 4,500 rpm for dynamic machining operations

- Robust power options – Delivers 5.5 kW in continuous operation or 7.5 kW for up to 30 minutes (optional upgrade to 7.5 kW / 11 kW)

- Versatile workholding – Features an A2-5 spindle nose accommodating chucks up to 210 mm (8 inch) in diameter

- Consistent cutting performance – Maintains constant torque between 1,125-4,500 rpm, ensuring stable machining results

To further enhance precision, the thermally optimized spindle bearing system reduces runout and guarantees maximum concentricity. Additionally, an intelligent cooling system with active temperature monitoring maintains stable machining conditions, even during continuous operation.

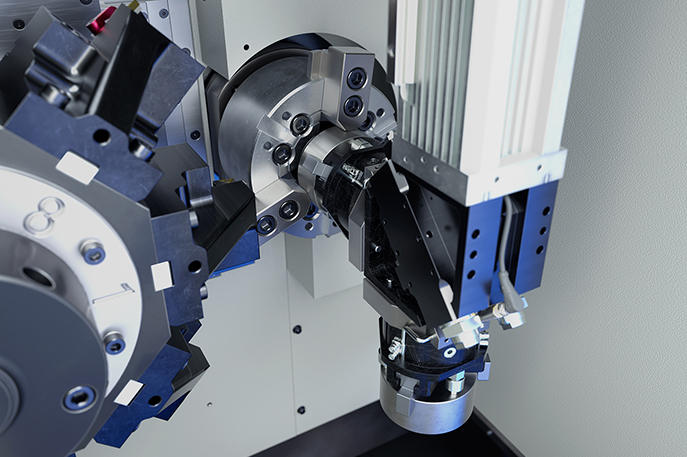

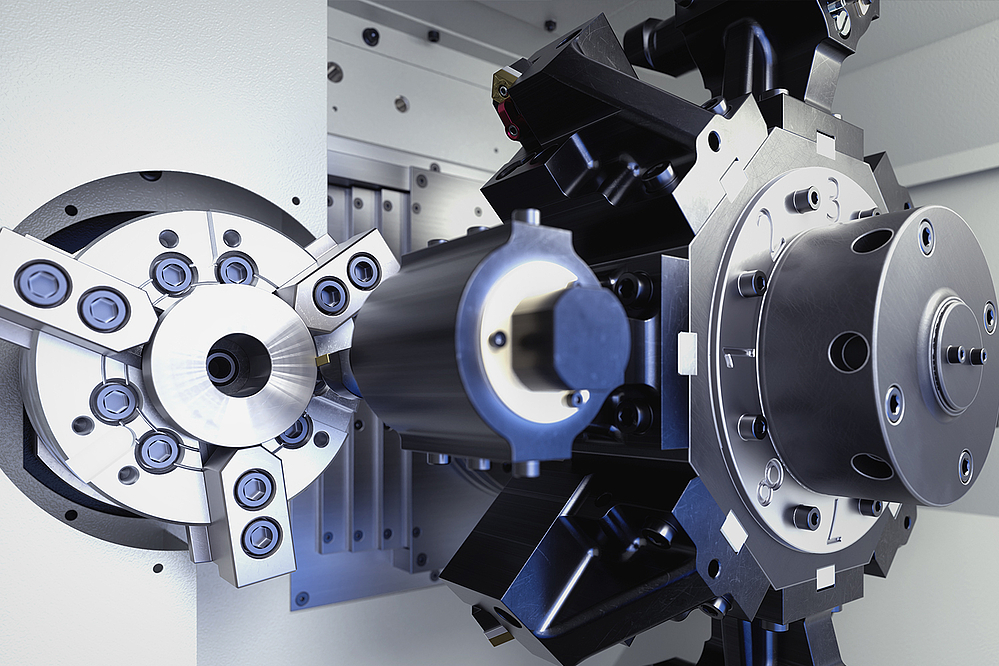

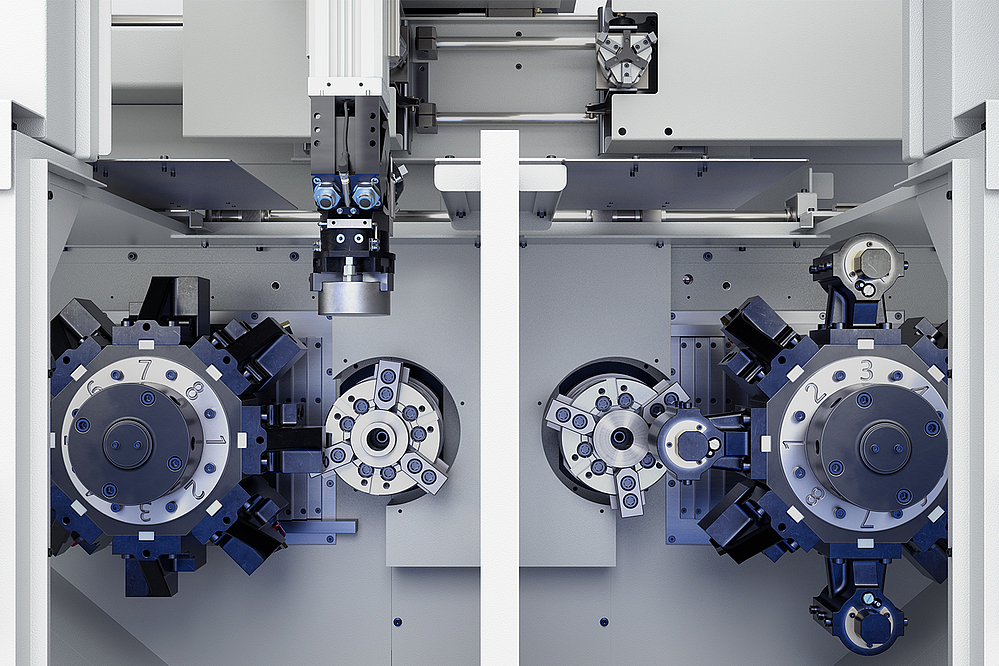

High precision turret system with optimized cooling

At the core of the MSC 5 DUO are two servo-controlled turrets, delivering high rigidity, fast tool changes and exceptional machining flexibility.

- Equipped with 8 standard tool positions

- BMT tool interface ensures maximum stability and rigidity for demanding machining operations

- Accommodates 25 x 25 mm shank tools for external machining

- Fast and precise tool indexing minimizes changeover times

- Hydraulic clamping system guarantees secure and accurate positioning

To further enhance machining quality, the advanced coolant management system is engineered for efficient heat dissipation, chip evacuation and tool longevity.

- Strategically positioned coolant nozzles provide effective cooling in the cutting area

- Enhanced flushing system ensures reliable chip removal, even with difficult materials

Targeted coolant supply extends tool life and improves surface finish quality.

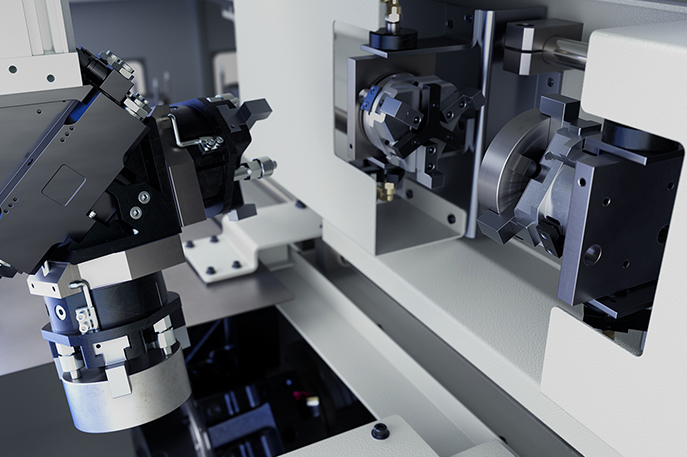

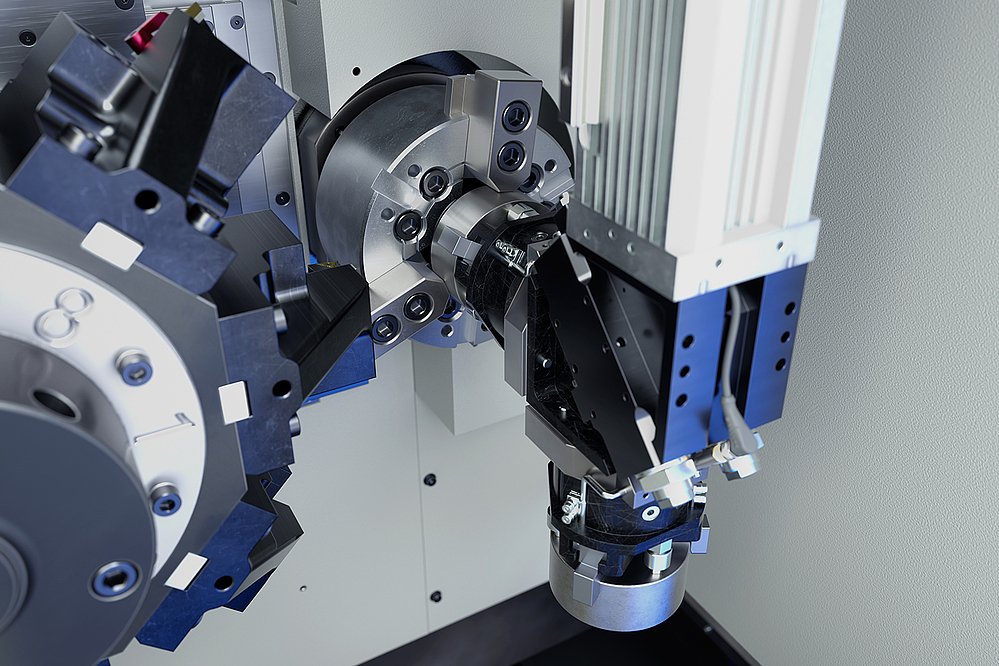

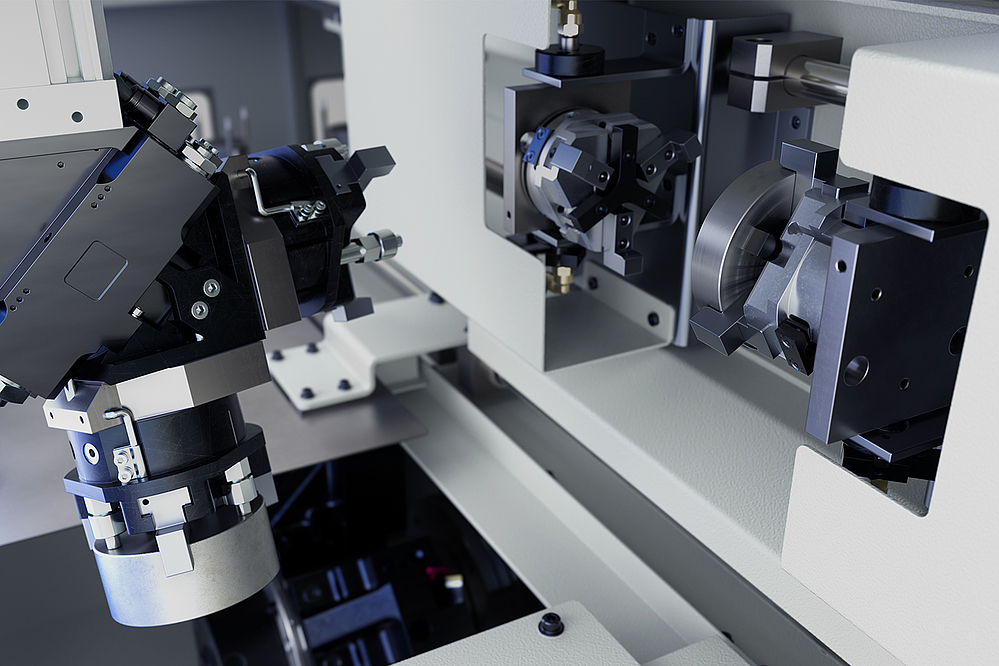

Efficient gantry loading system for maximum productivity

Integrated 3-axis gantry loading system

The fully integrated 3-axis gantry loading system streamlines automation by precisely loading and unloading workpieces with minimal downtime. Designed for high-speed production, it ensures seamless operation with::

- Fast loading and unloading to reduce cycle times

- Servo-driven axes for precise and reliable part handling

- Integrated part turner enabling complete machining on both sides

- Customizable workpiece pallets to accommodate various geometries

- Automated workpiece feed and removal for efficient production with reduced labor requirements

Compact stacking storage system

The stacking system (stacker) for raw and finished parts integrated into the machine saves valuable space and enables automation without additional footprint. The flexible pallet system can be adapted to different workpiece diameters.

Simple servicing for minimal downtime

When designing the MSC 5 DUO lathe, special emphasis was placed on easy servicing:

- Easily accessible service components for quick maintenance

- Ergonomic tool change from the front

- Clear fault diagnosis of the control unit for fast troubleshooting

- Direct access to the workpiece gripper system

- Large work area door for changing tools and retooling components

These well-thought-out details reduce downtimes for maintenance work to a minimum and contribute to the high availability of the machine.

Optimal areas of application for the MSC 5 DUOThe MSC 5 DUO is particularly suitable for:

|

MSC 5 DUO - Component of the EMAG Classic series

The MSC 5 DUO is part of the EMAG Classic series, which is characterized by clarity, efficiency and economy and is the ideal entry-level solution into the world of EMAG.

Features of the EMAG Classic series:

- Optimized basic machines equipped with proven EMAG technologies

- Worldwide service with full access to the global service network

- Focus on low investment budgets with maximum efficiency

- Reduced selection of options with a focus on high-productivity soft turning

Advantages MSC 5 DUO

- Reduced downtime with automated loading and unloading

- Increased efficiency through simultaneous machining on both spindles

- Quick changeovers enabled by a sophisticated tool concept

- Superior machining quality for precise and consistent results

- Energy-efficient drives for lower operating costs

- Minimal maintenance with a service-friendly design