Modular – Chucked Components – VL/VM

VL 6

- Workpiece dia., max.: 300 mm | 12 in

- Workpiece length, max.: 250 mm | 10 in

- Chuck dia., max.: 400 mm | 15.5 in

VL 6 – Vertical Lathe for the Machining of Heavy Workpieces up to 300 mm in Diameter

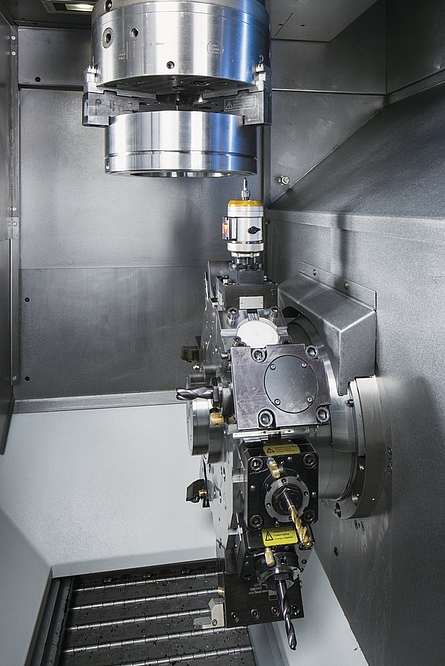

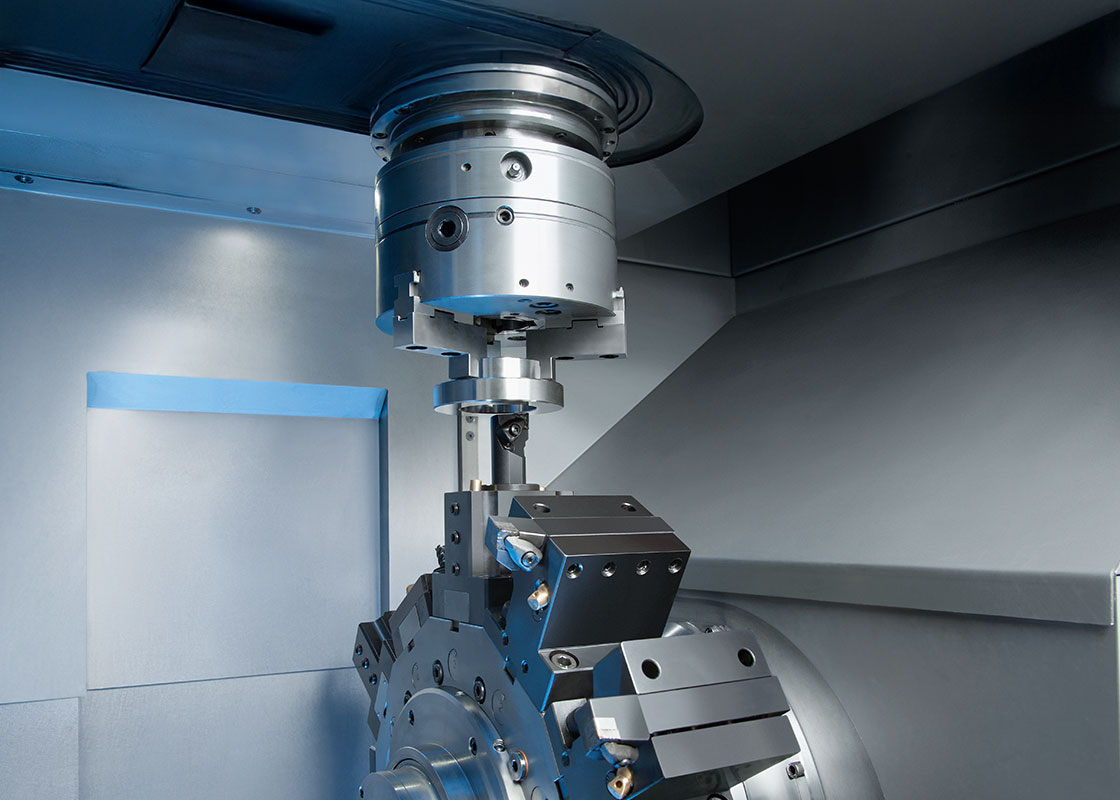

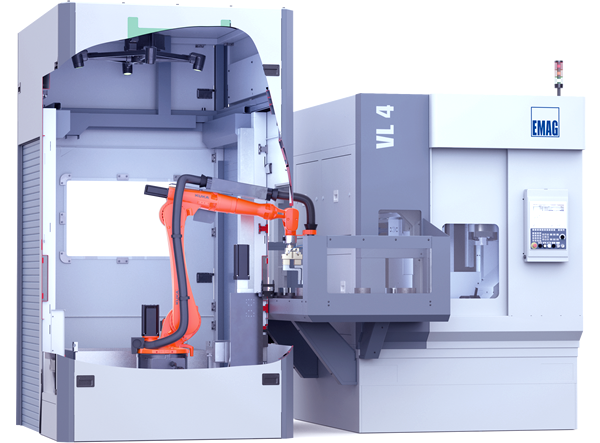

The VL 6 vertical lathe machine offers the same features as the newest EMAG modular designs in a vertical turning machine for larger, heavy workpieces. Equipped with a standard workpiece conveyor and pick-up spindle, the cnc lathe machine loads itself with minimized chip-to-chip times. With a machine base made of the polymer concrete MINERALIT®, a material well-known for its excellent damping quality, it offers extended tool life and outstanding surface finishes.

Vertical Lathe with Pick-Up Automation for Efficient Machining

With the goal to develop a system of modular machines ideal for use in the manufacturing of medium and large batch runs, one common feature of all the new EMAG modular machines is the basic, compact design. Their small footprint means reduced floor space costs and flexibility in machine layout (for example, Chaku Chaku or closed loop arrangement). Every VL vertical lathe features an integrated O-automation system for transporting workpieces on its left-hand side. When combined with the self-loading pick-up spindles, this automation concept ensures short cycle times and high productivity.

To accommodate machine operators, all the service units are easily within reach, with various units (electrics, hydraulics, cooling system, cooling lubricant and central lubrication system) accessible at any time so that the vertical lathes can be maintained with ease. With low maintenance costs due to the use of standardized components, excellent accessibility, reduced floor space costs, integrated automation and short cycle/idle times bringing the cost per unit to a minimum, the goal of EMAG vertical lathes is clear: cost saving without compromising quality.

EDNA IOT-READY EX-WORKS: Get started with data-optimized production with VL series

Using data analysis, unnecessary downtimes – due to component wear or, in the worst case, due to the failure of a machine – can be reduced or even avoided entirely. Productivity increases of over 10% are the rule here. To make entering the world of data-optimized production as easy as possible for our customers, all the machines of the VL Series now come standard in an IoT-ready state. This means that data analysis on the machines can be started virtually immediately.

Advantages VL 6

- Integrated measuring (optional)

- Small footprint

- Very short chip-to-chip times

- Ideal chip flow conditions

- High degree of availability

- Short travel time for loading and machining, resulting in shortest possible cycle times

- Automatic workpiece changeover

- Integrated automation, low capital outlay

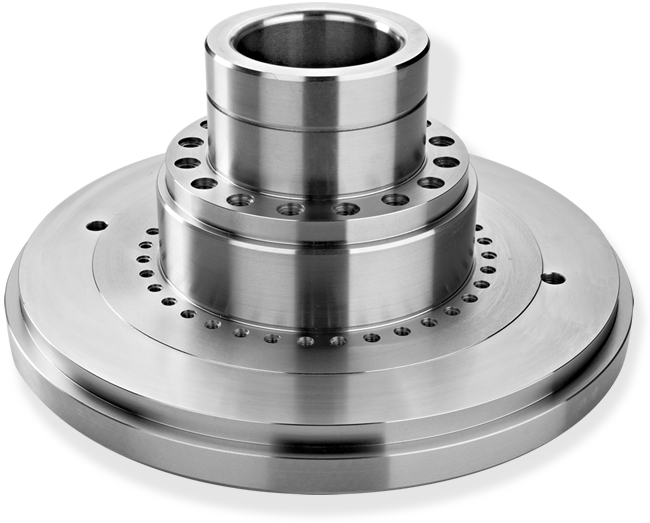

Workpieces

The Right Manufacturing Solution for Every Workpiece

Technologies

Complex Manufacturing Systems from a Single Source thanks to a High Range of Technologies

Vertical turning is a machining process for metal components. EMAG was one of the first machine tool manufacturers to use the vertical turning process…

Automation Solutions

Complete Manufacturing Lines or Automation Systems from EMAG

Technical Data

Workpiece dia., max.

300 mm

12 in

Workpiece length, max.

250 mm

10 in

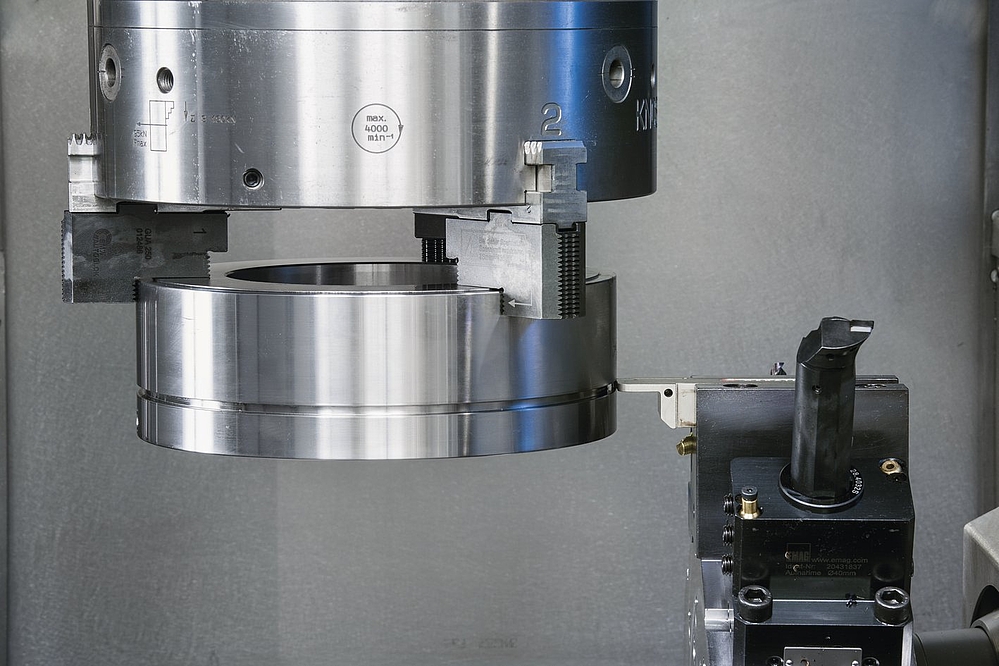

Chuck dia., max.

400 mm

15.5 in

| Workpiece dia., max. |

mm

in |

300

12 |

| Workpiece length, max. |

mm

in |

250

10 |

| Chuck dia., max. |

mm

in |

400

15.5 |

| Swing diameter |

mm

in |

420

16.5 |

| X-axis travel |

mm

in |

900

35.5 |